Load driving device

A technology of load drive and power storage device, which is applied in the direction of control drive, circuit device, output power conversion device, etc., can solve the problems of high cost, increased assembly man-hours, large configuration space, etc., and achieves simple structure, common mode noise, etc. Reduction effect increases, common mode noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

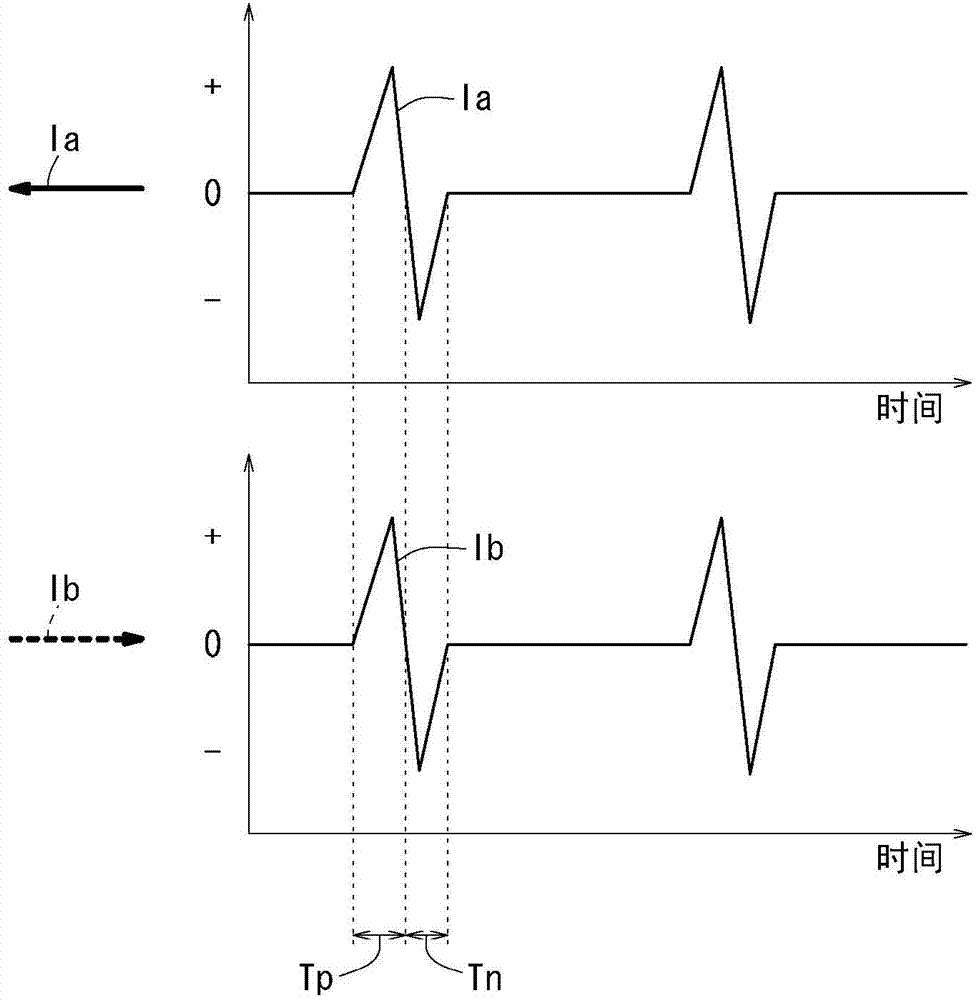

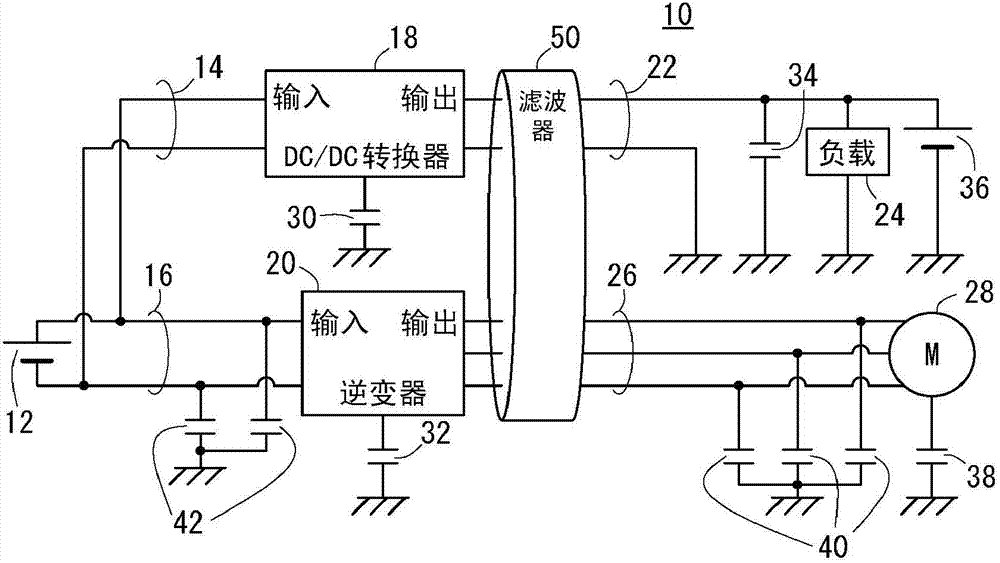

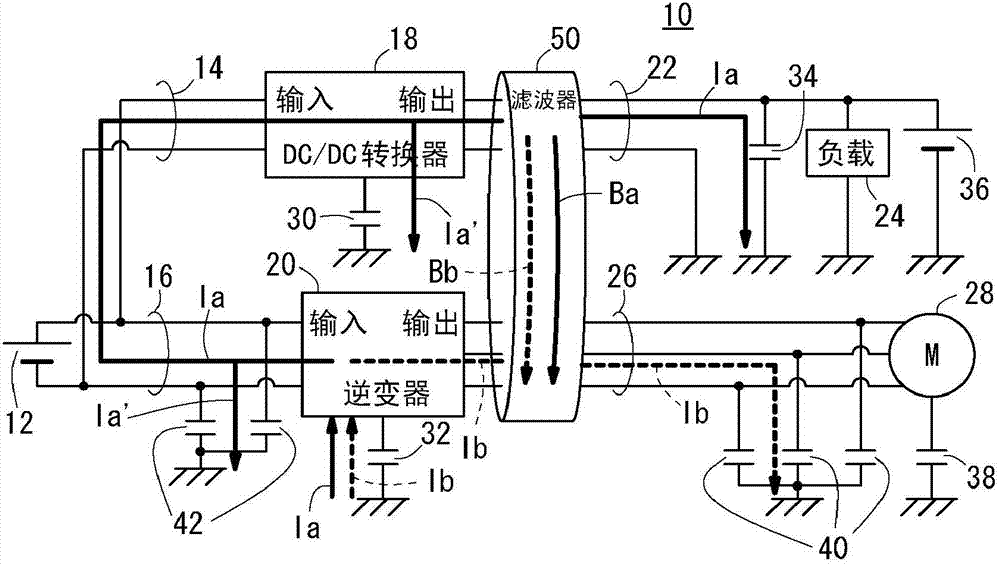

[0062] Figure 2A It is a configuration diagram of a load driving device 10 according to the first embodiment of the present invention applied to an electric vehicle. Figure 2B It is an explanatory diagram of the common mode noise reduction operation in the load driving device 10 according to the first embodiment.

[0063] exist Figure 2A , Figure 2B Among them, the load driving device 10 basically includes: a high-voltage power storage device 12 as an energy storage such as a lithium-ion secondary battery, a capacitor, and the like; Converter 18 (power conversion device) and inverter 20 (power conversion device); load 24 (auxiliary load) connected through output side power line 22 of DC / DC converter 18 ; output through inverter 20 A three-phase electric motor (motor) 28 as a main load connected to the side power line 26 .

[0064] An output shaft of the electric motor 28 is engaged with drive wheels via a transmission not shown.

[0065] The DC / DC converter 18 and the...

no. 2 example

[0100] Next, a second embodiment will be described. Including this second embodiment, in the third to fifth embodiments described later, the same components as those shown in the above-mentioned first embodiment or corresponding components are assigned the same symbols, and A detailed description thereof is omitted.

[0101] Figure 5A It is a configuration diagram of a load driving device 10A of the second embodiment in which a motor 28 is driven from a DC power supply 12A (it may also be a power storage device) via an inverter 20 , not limited to an electric vehicle. Figure 5B It is an explanatory diagram of the common mode noise reduction operation in the load driving device 10A according to the second embodiment.

[0102] The load driving device 10A can be applied as an example for driving the motor 28 for cooling fans of electronic equipment such as notebook computers or the motor 28 for electric compressors, wherein the motor for cooling fans of electronic equipment s...

no. 3 example

[0112] Next, a third embodiment will be described.

[0113] Figure 6 It is a configuration diagram of a load driving device 10B according to the third embodiment applicable to an electric vehicle. Figure 7 It is an explanatory diagram of the common mode noise reduction operation in the load driving device 10B according to the third embodiment.

[0114] exist Figure 6 , Figure 7 Among them, the load driving device 10B basically includes: a high-voltage power storage device 12; and a DC / DC converter 18 (power conversion device) connected to the high-voltage power storage device 12 through input-side power lines 14, 16, 64, and 66 on the input side. , inverter 20 (power conversion device), air conditioner inverter (A / C inverter) 68 (power conversion device), generator inverter (GEN inverter) 70; by DC / DC conversion A load 24 (auxiliary load) connected to the output side power line 22 of the inverter 18; a three-phase electric motor (motor) 28 for driving the front wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com