Motor system capable of lowering common mode noise

A common-mode noise and motor technology, applied in the control system, output power conversion device, conversion equipment for intermediate conversion to DC conversion, etc., can solve the problems of complex circuits, inability to control chips to obtain clean feedback signals, etc., to reduce Effects of Common Mode Noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

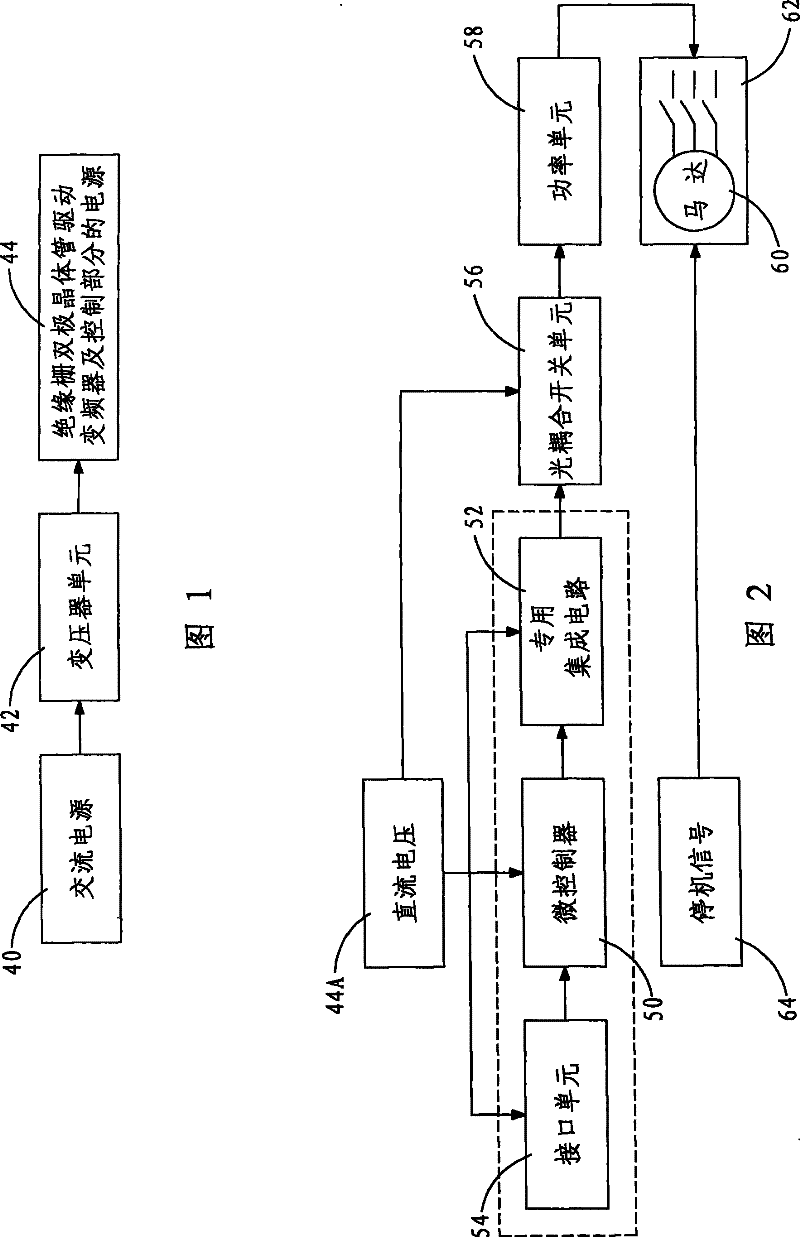

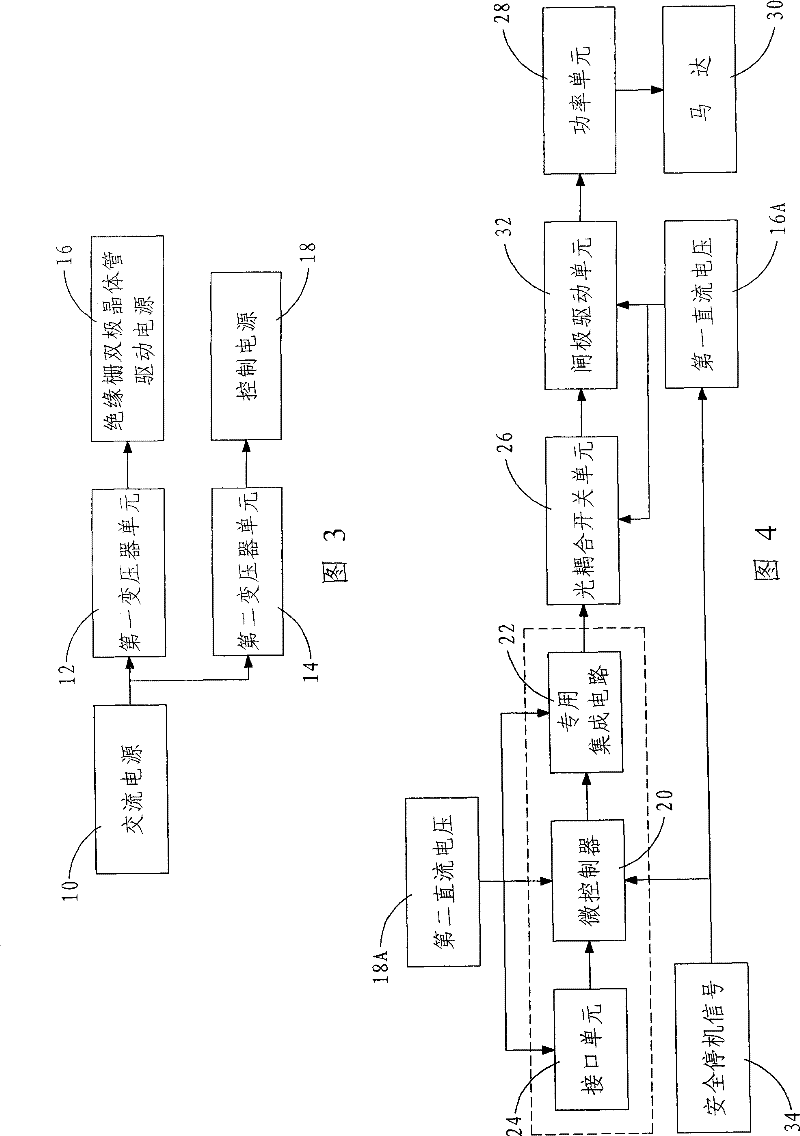

[0035] Referring to FIG. 3 , it is a block diagram of a motor power supply device capable of reducing common mode noise according to the present invention. The motor power supply device capable of reducing common mode noise mainly includes an alternating current (AC) power supply 10, a first transformer unit 12 and a second transformer unit 14 electrically connected to the alternating current (AC) power supply 10, and an IGBT drive power supply 16 connected to the first transformer unit 10. A transformer unit 12 and a control power source 18 are connected to the second transformer unit 14 . The above circuit constitutes the motor power supply device of the present invention, and independent transformers are used for the driving power supply and the control power supply, which can prevent the noise generated by the driving circuit from being coupled to the control power supply. In this circuit, the first transformer unit 12 and the second transformer unit 14 may include a recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com