Method for manufacturing cylindrical components

A technology for cylindrical parts and components, applied in the field of reprocessing cylindrical parts, can solve the problems of reducing the elongation at break, reducing the mechanical strength of castings, etc., and achieve the effect of a small amount of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

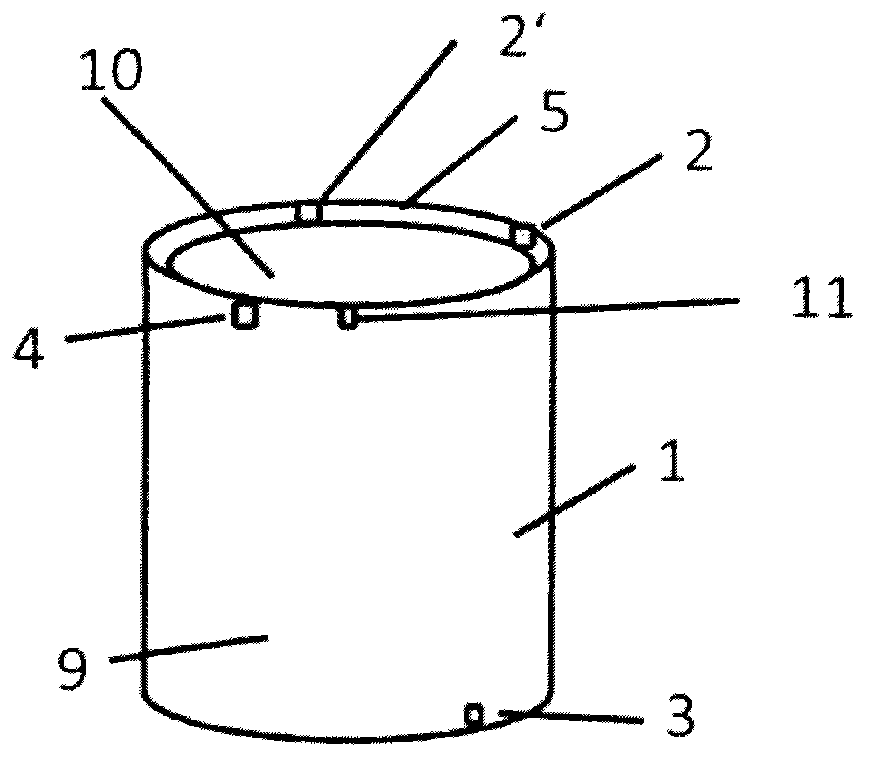

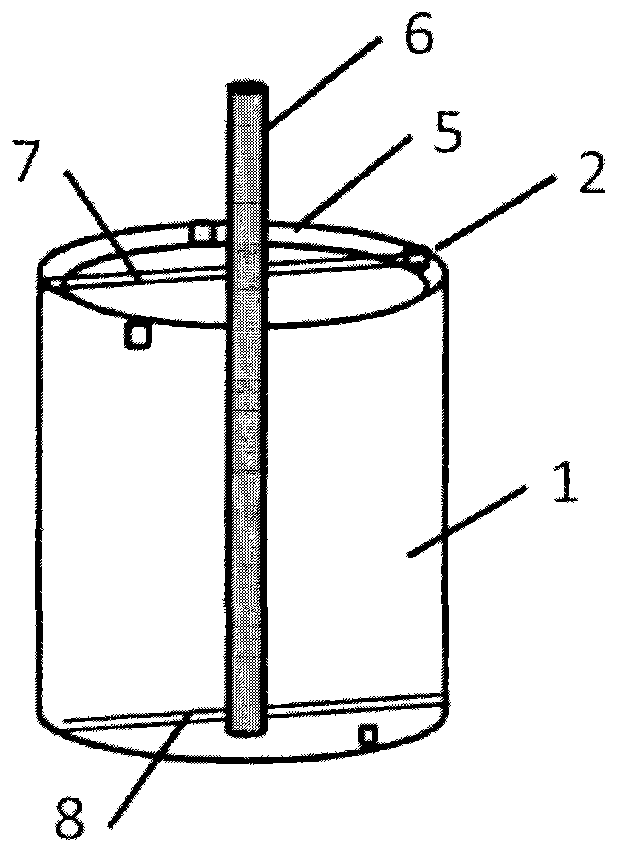

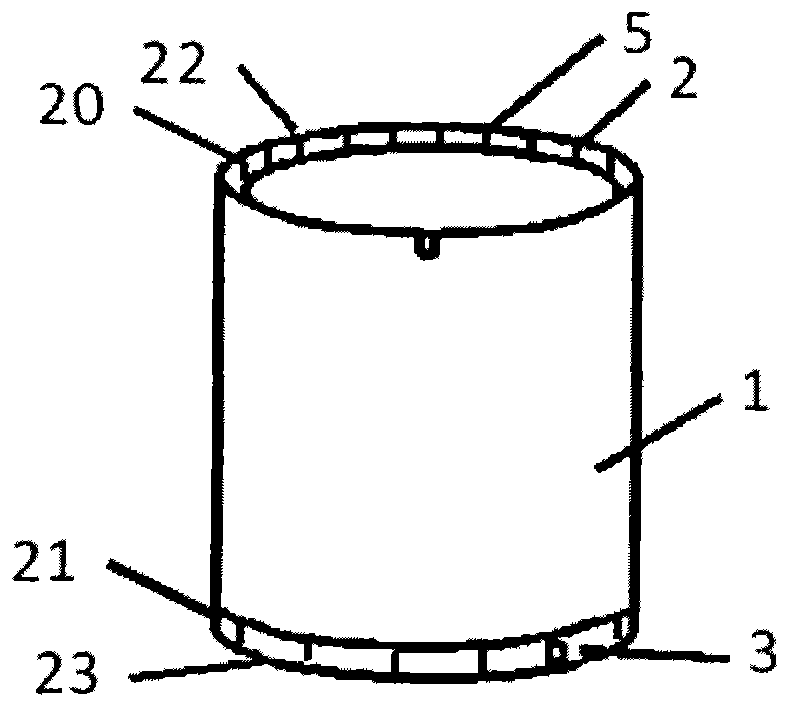

[0018] figure 1 An example of a cylindrical part is shown, which in this embodiment is open at both end faces 22 and 23 . The cylinder 1 has an outer surface 9 and an inner surface 10 .

[0019] The cylinder is cast as a casting with at least one lug 3 on the lower periphery of the cylinder and / or at least one lug 11 on the upper periphery. The function of the lugs 3 and 11 is explained below. The cylinder 1 has a subregion 5 along the edge of the inner surface 10 . This subregion 5 is not used for subsequent surface treatment. The bearing surfaces 2 and 2 ′ are present in a subregion 5 . The bearing surface 4 is also shown by way of example on the housing 9 .

[0020] In the production process, in the first step, the cylinder 1 is cast out of aluminum alloy, corresponding to Figure 4 Step S1 in . The casting mold includes a central core and an outer mold in which lugs are provided. After casting, the blank casting is coded, the position of the blank casting being cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com