Drill lip automatically sticking and adhering device

An automatic and sticky technology, applied in the direction of grinding/polishing safety devices, drilling tool accessories, drilling/drilling equipment, etc., can solve the problem of production yield decline, poor chip removal efficiency, visual misjudgment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

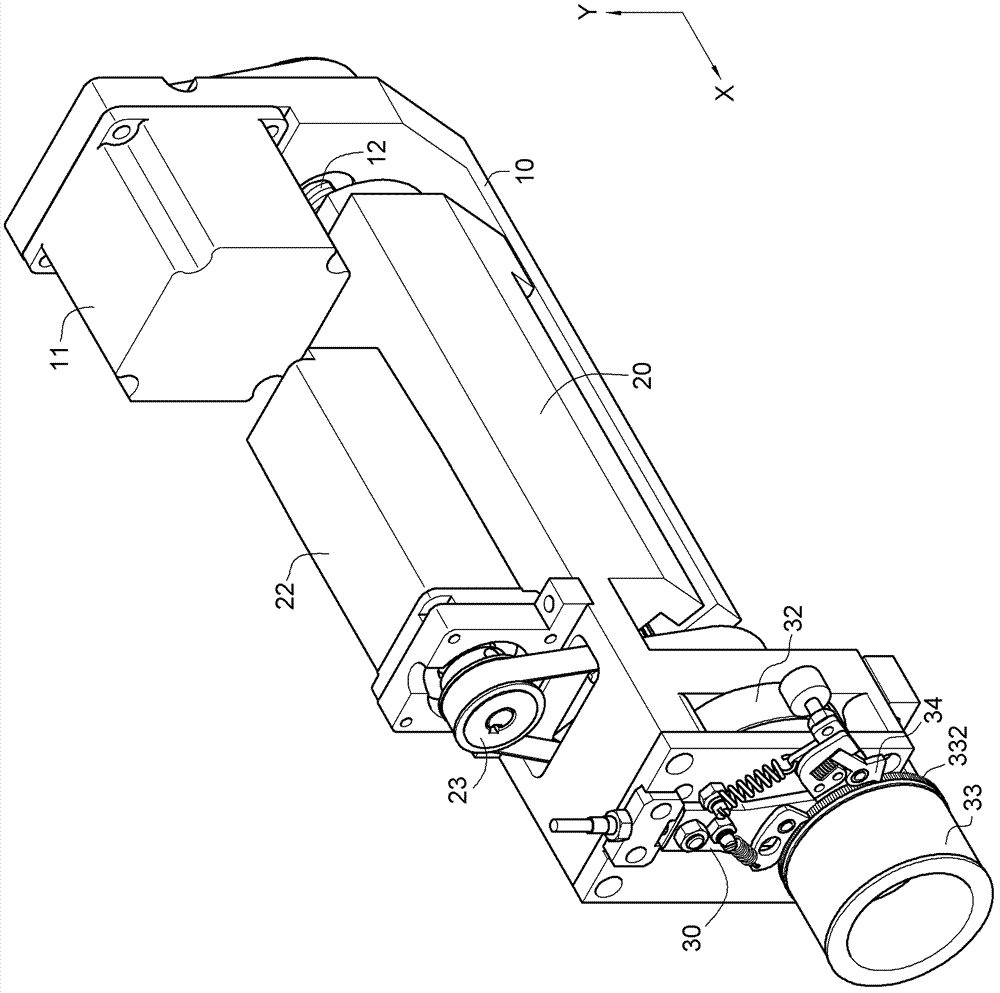

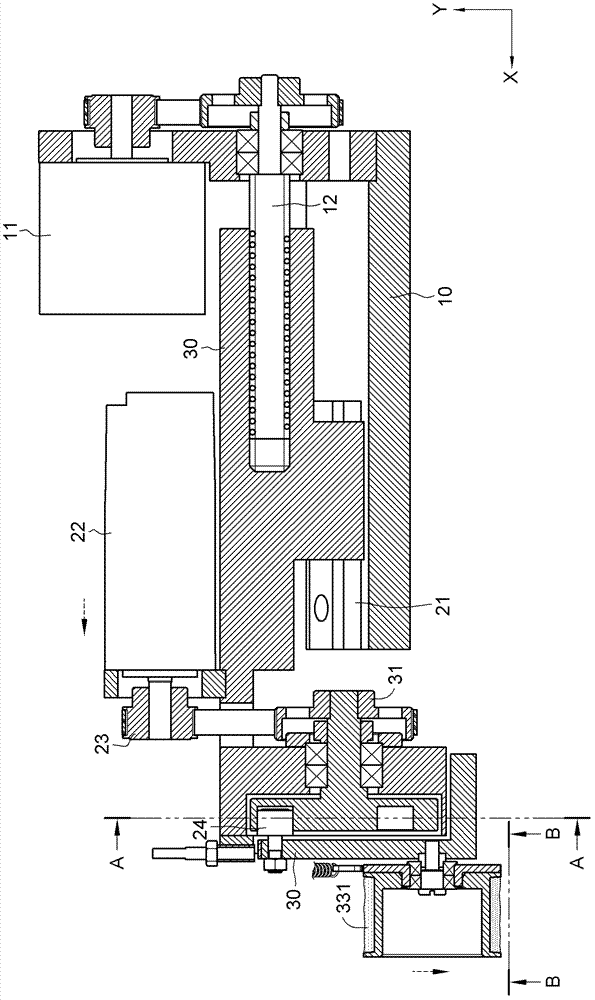

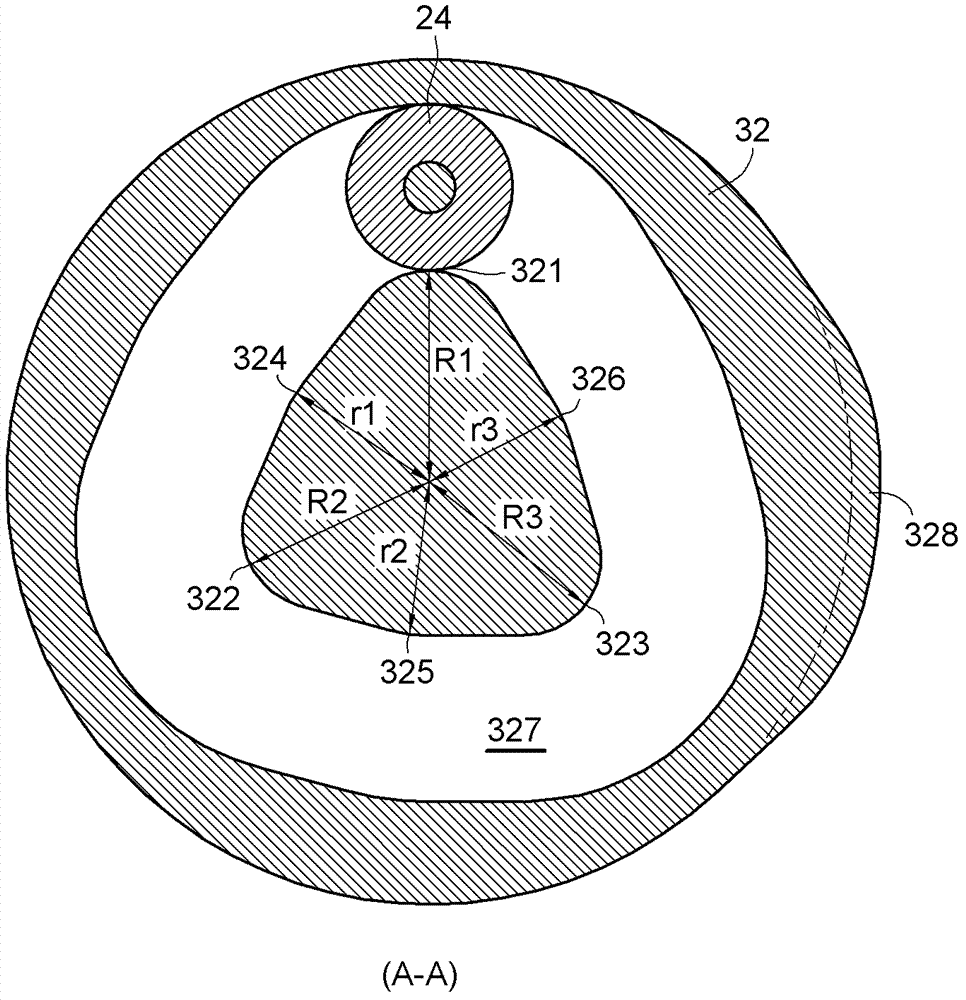

[0032] First view figure 1 As shown, the present invention provides an automatic sticking device for a drill blade, which includes a first sliding table 20 slidably arranged on a supporting and positioning base 10, and a first sliding table 20 is slidably arranged on the first sliding table 20 Two sliding tables 30 to implement the assembly of the following components:

[0033] Different linear axes are defined on the base 10, and the linear axes include an X axis and a Y axis. The base 10 is provided with a first driver 11, and the first driver 11 can essentially be a motor. Or other components that can push objects to perform X-axis linear displacement operations. The output end of the first driver 11 is connected to a ball screw 12 (with figure 2 As shown), the ball screw 12 is driven to produce linear reciprocating movement in the X-axis.

[0034] Between the first sliding table 20 and the base 10 is a sliding rail 21 (such as figure 2 (Shown), the first sliding table 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com