Rear wall shape designing method for square-cone pulp distribution header of pulp flow tank

A design method and headbox technology, applied in textiles and papermaking, paper machine, paper machine wet end, etc., can solve problems such as uneven distribution of slurry, and achieve the effect of ensuring rationality and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

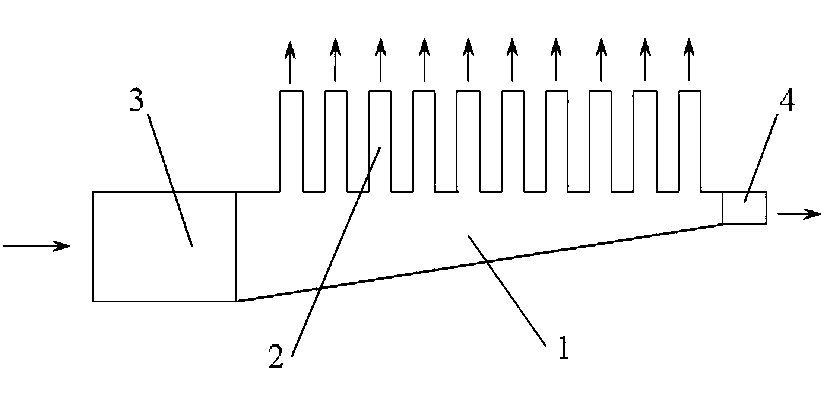

[0023] refer to figure 1 , The square cone tube slurry distributor of the present invention is composed of a square cone main pipe 1 and a branch pipe bundle 2. One end of the square cone main pipe 1 feed port has a transition pipe 3, and the other end is a return end 4.

[0024] A method for designing the shape of the rear wall of a headbox square cone main pipe provided by the invention comprises:

[0025] a. Use GAMBIT software to conduct geometric modeling and grid division of the square cone slurry distributor, and set the boundary type to generate the header.msh file;

[0026] b. Import the header.msh file into the FLUENT software, check the grid quality, set the flow model, medium, and boundary conditions, perform automatic solution and post-processing of the results, and output the calculation results;

[0027] c. Use iSIGHT software to analyze the calculation results;

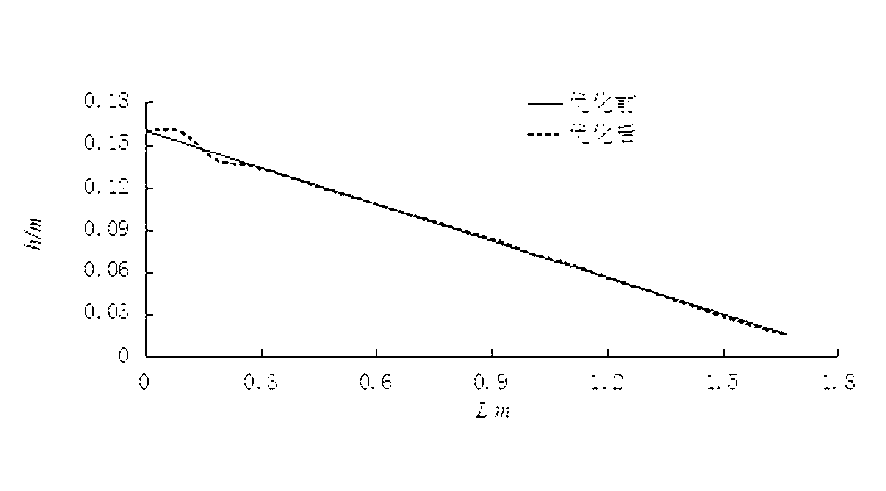

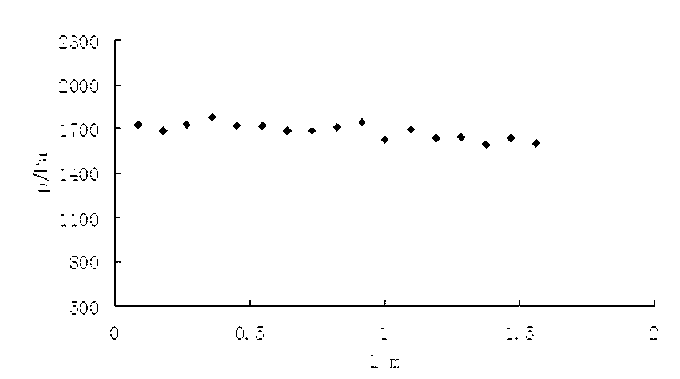

[0028] If in the calculation result of step c, the deviation of the slurry distribution mass flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com