Adjustable temperature control valve

A temperature-controlled valve and adjustable technology, applied in the direction of lubricating oil control valve, valve details, valve device, etc., can solve the problems of affecting valve opening, high cost, fatigue damage, etc., to save component costs and labor costs, Ease of manufacture and use, the effect of reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

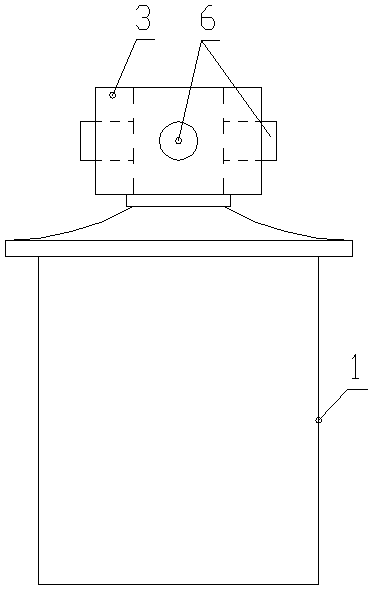

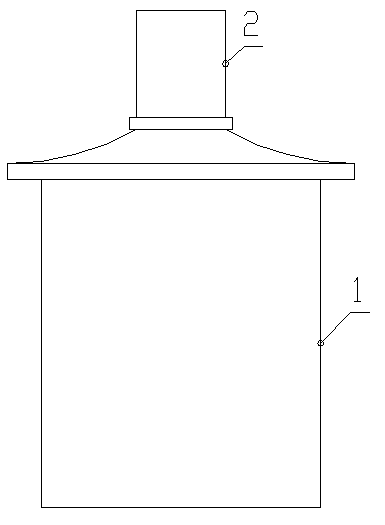

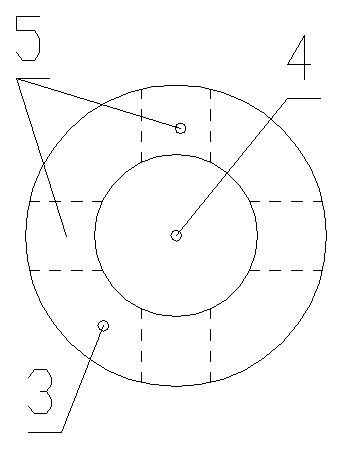

[0010] Such as Figure 1 to Figure 3 As shown, the adjustable temperature control valve of the present invention includes a valve body 1, a cylindrical thermal element 2 is connected to the middle of one end of the valve body 1, and an expansion control sleeve 3 is sleeved on the radial circumferential surface of the thermal element 2. The expansion control sleeve 3 The inner hole 4 is adapted to the outer diameter of the thermal element 2, specifically, the inner hole 4 and the thermal element 2 are tightly fitted. The expansion control sleeve 3 is evenly distributed with three or more radially arranged bolt through holes 5 along its circumferential direction, and each bolt through hole 5 is screwed with an adjusting bolt 6 . The bolt through holes 5 and the adjusting bolts 6 are preferably provided with four respectively.

[0011] When in use, since the inner hole 4 of the expansion control sleeve 3 in the present invention is adapted to the outer diameter of the thermal el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com