Center pipe fixation member

A technology for fixing parts and central pipes, applied in the field of filtration equipment and water softening, can solve the problem of bringing out the central pipe and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

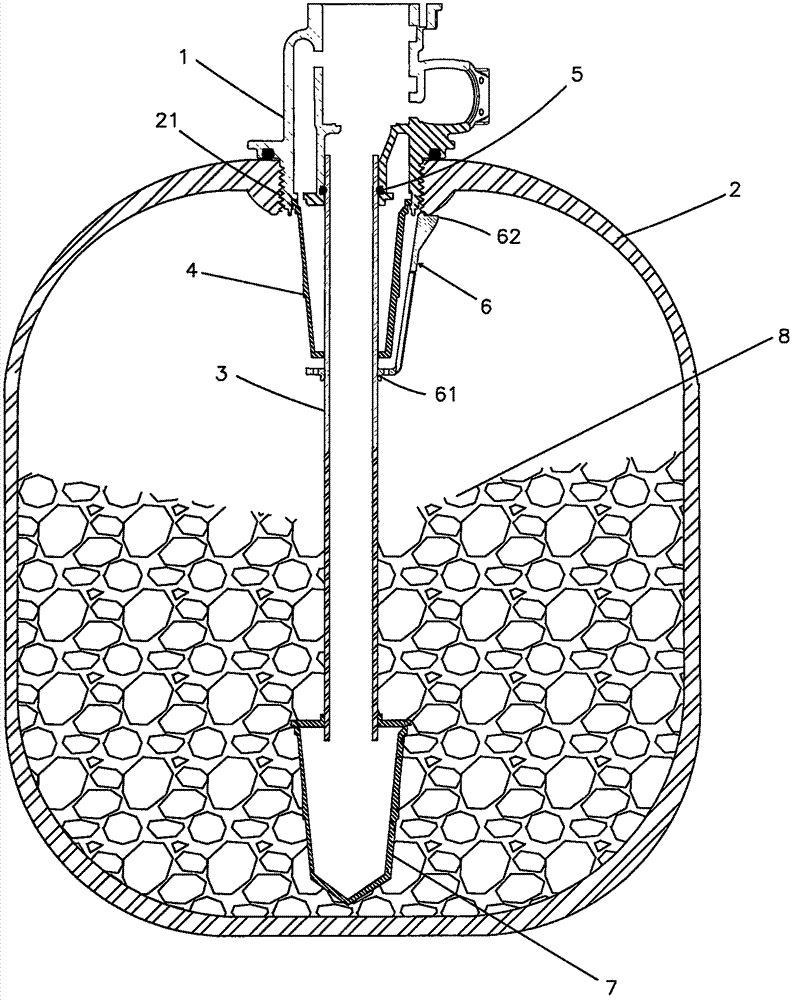

[0019] Such as figure 1 As shown, the control valve 1 and the upper water cap 4 are connected together by the threaded opening, that is, the tank mouth 21 and the tank body 2. There is a gap on the upper water cap 4 for passing water and preventing the filter material from leaking out. The central pipe 3 is buried in the filter material layer 8, and the upper end is inserted into the control valve 1 below the upper water cap 4 with a loose fit, and is sealed with the central pipe O-ring 5.

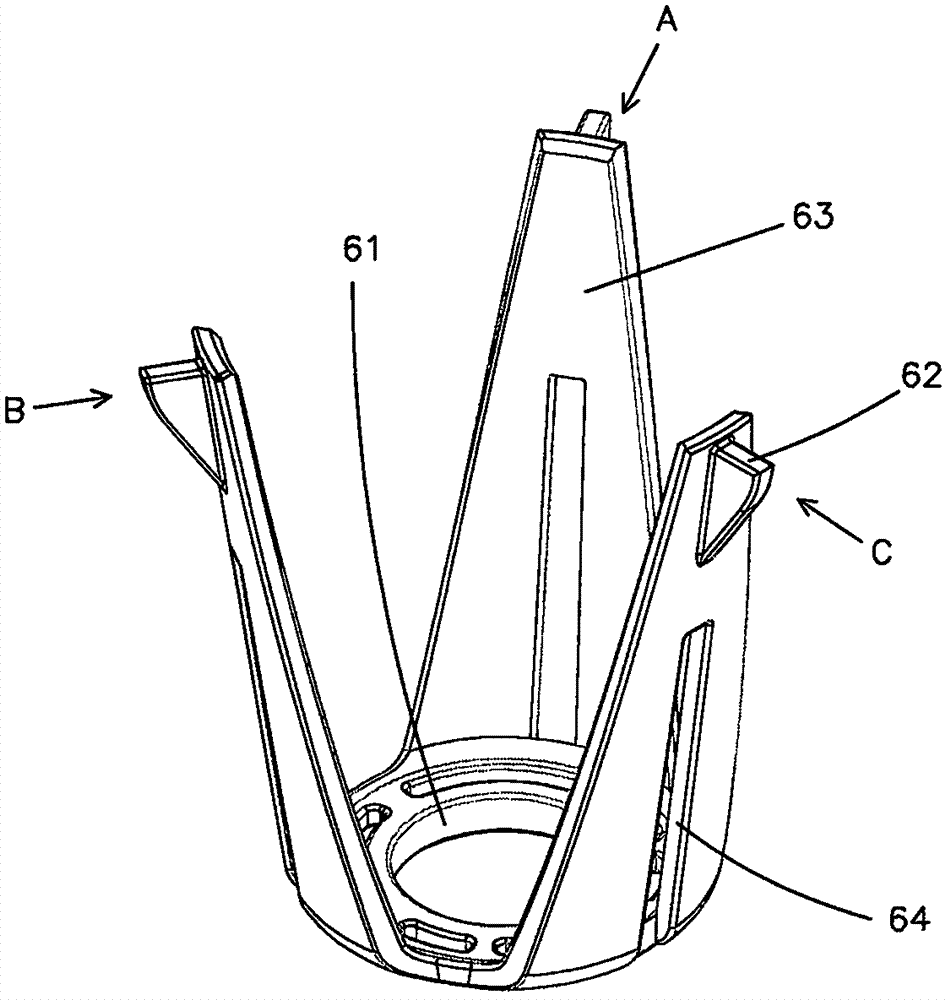

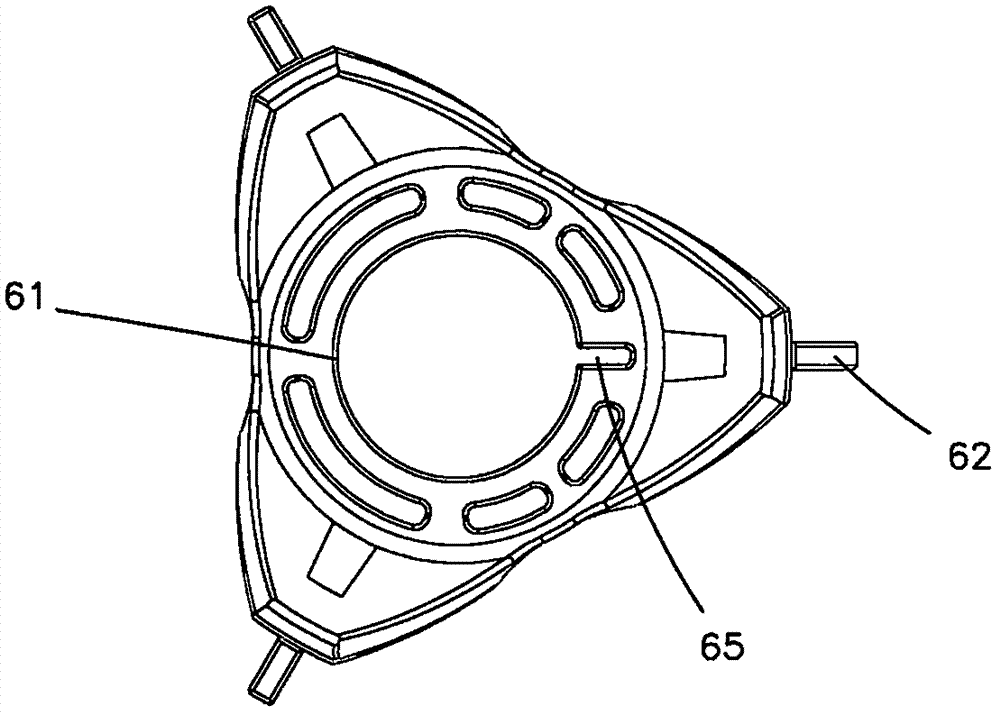

[0020] The central tube fixing part 6 is fastened to the proper position on the central tube 3 by tight fitting at the fixing hole 61, so that the platform 62 of the three claws on the central tube fixing part 6 is just stuck on the lower end of the tank mouth 21, when the control valve is disassembled 1, due to the friction caused by the O-ring 5 being compressed, it will drive the center tube 3 to move up together. At this time, the fixed part 6 fixed on the center tube 3 will also move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com