Zero power starting method of thermal generator set with high-voltage direct-current transmission system

A technology for thermal power generating units and power transmission systems, which is applied to output power conversion devices, power transmission AC networks, electrical components, etc., to reduce voltage fluctuation problems, facilitate assembly and disassembly, and have excellent control capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] The inventive method comprises the following steps:

[0023] 1) Determination of equipment parameters of flexible direct current transmission system

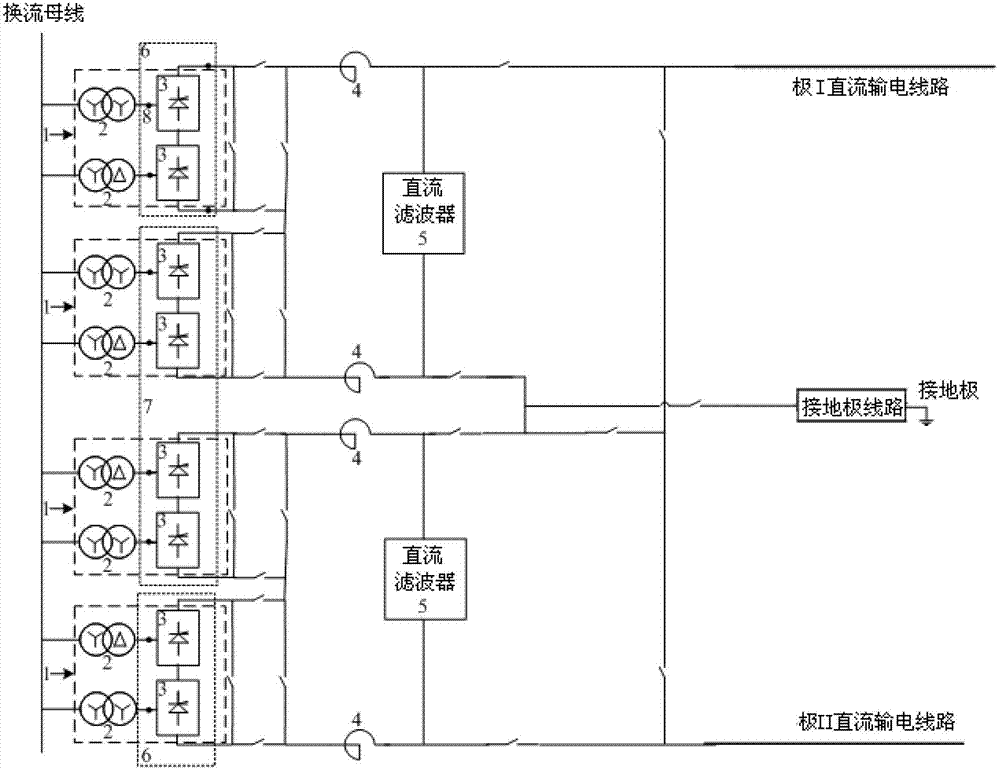

[0024] The invention combines the flexible direct current transmission technology and the high voltage direct current transmission technology to solve the problem of zero-power start-up of the high voltage direct current transmission system in the thermal power base belt. Therefore, the high-voltage direct current transmission system will be introduced first: the high-voltage direct current transmission system is usually composed of a sending-end and a receiving-end converter station, and the main wiring of the two converter stations is the same. Such as figure 1As shown, each end converter station usually includes symmetrical pole I and pole II. Each pole usually includes two series-connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap