Full-automatic spring winding and cutting machine

A fully automatic, wire-winding technology, which is applied to the manufacture of springs from wires, other household appliances, household appliances, etc., can solve the problems of low production efficiency, waste of labor, and low pass rate of manual measurement and cutting of springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

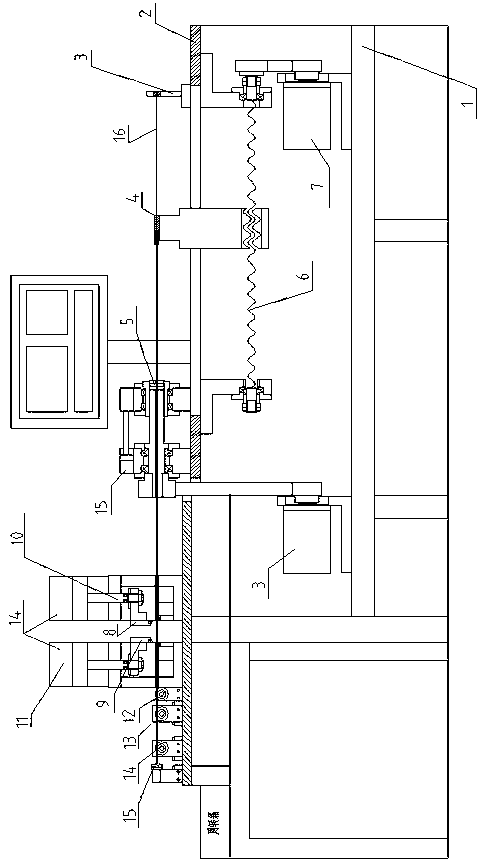

[0008] Such as figure 1 As shown, the fully automatic winding spring cutting machine includes a frame 1, a wire winding mechanism 5, and a wire breaking mechanism 14. A working platform 2 is arranged on the upper end of the frame 1, and the wire winding mechanism 5 and the breaking wire mechanism 14 are fixed on the working platform. 2, the wire winding mechanism includes a steel wire support 3, a special clamp 4, and a wire winding device 15. The special clamp 4 is arranged on the left side of the steel wire support 3, and the wire winding device 15 is arranged on the left side of the special clamp 4. Connect the ball screw 6, one end of the ball screw 6 is connected to the motor 7, the wire breaking mechanism 14 includes a first wire cutting knife 8, a second wire breaking knife 9, two wire breaking knife brackets 11, and the second wire breaking knife 9 is set On the left side of the first wire breaking knife 8, the upper ends of the first and second wire breaking knives 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com