Sliding mechanism

A technology of sliding mechanism and slide rail, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as troublesome operation, achieve the effect of preventing accidental retreat, simple overall structure, and solving the mutual interference of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

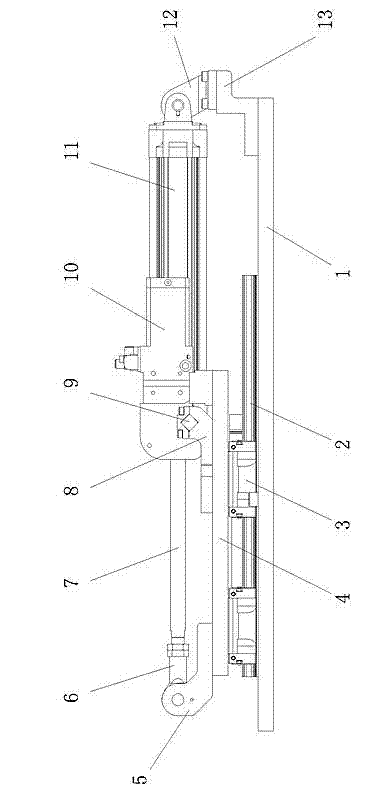

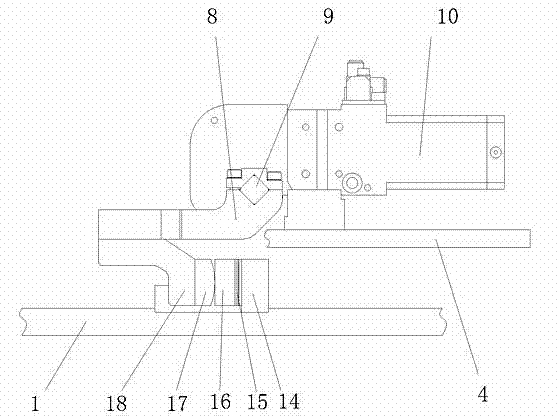

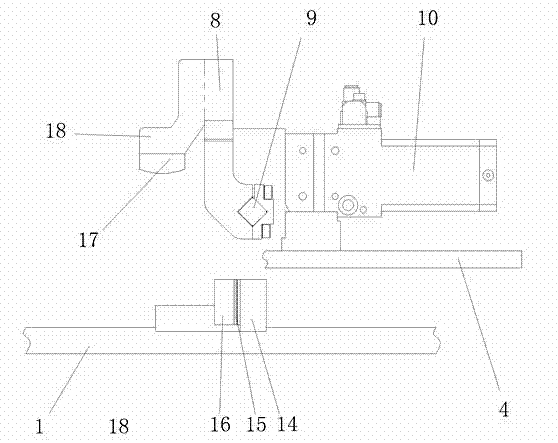

[0009] Such as figure 1 Shown: 1 is the base, on the base 1 are fixedly connected two slide rails 2 arranged in parallel, and each slide rail 2 is equipped with two slide blocks 3, and each slide block 3 is fixedly connected to the bottom surface of the platform 4, The platform 4 is supported on the base 1 through a sliding connection. A support 13 is fixedly connected to one end of the base 1, and one end of the driving cylinder 11 is rotatably connected to the support 13 through a connecting frame 12 and a pin shaft. The outer end of the piston rod 7 matched with the driving cylinder 11 is threadedly connected with a connecting rod 6 , the connecting rod 6 is connected with the connecting head 5 through a pin shaft, and the connecting head 5 is fixedly connected with the platform 4 . When the driving cylinder 11 works, it can drive the platform 4 to slide. A rotary cylinder 10 is fixedly installed on the platform 4 , and the output rotating shaft 9 matched with the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com