Foam caulking gun with safety mechanism

A safety mechanism and caulking technology, which is applied to building structures, single handheld devices, spraying devices, etc., can solve problems such as inability to pull, inability to rotate, inaccurate adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

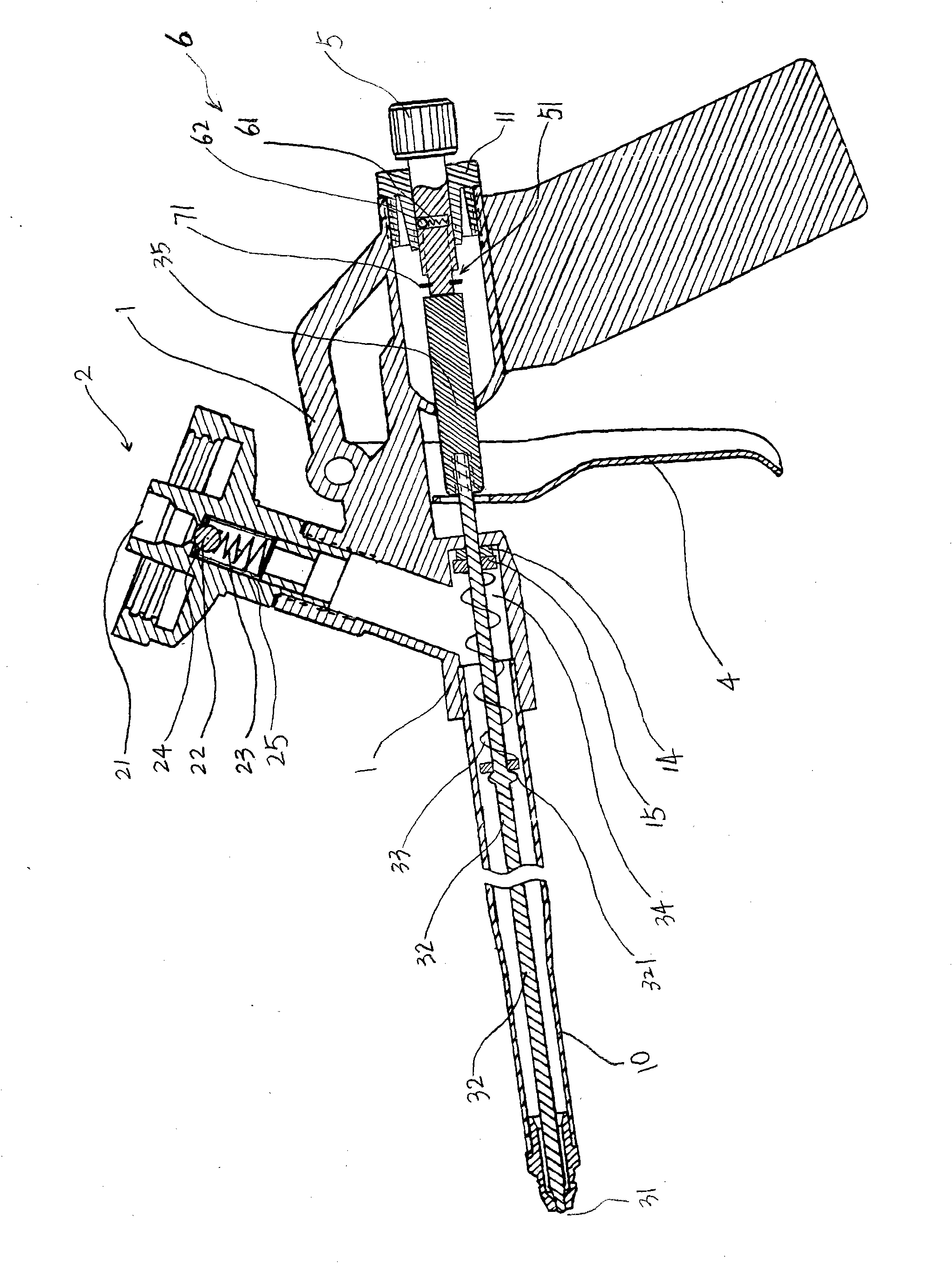

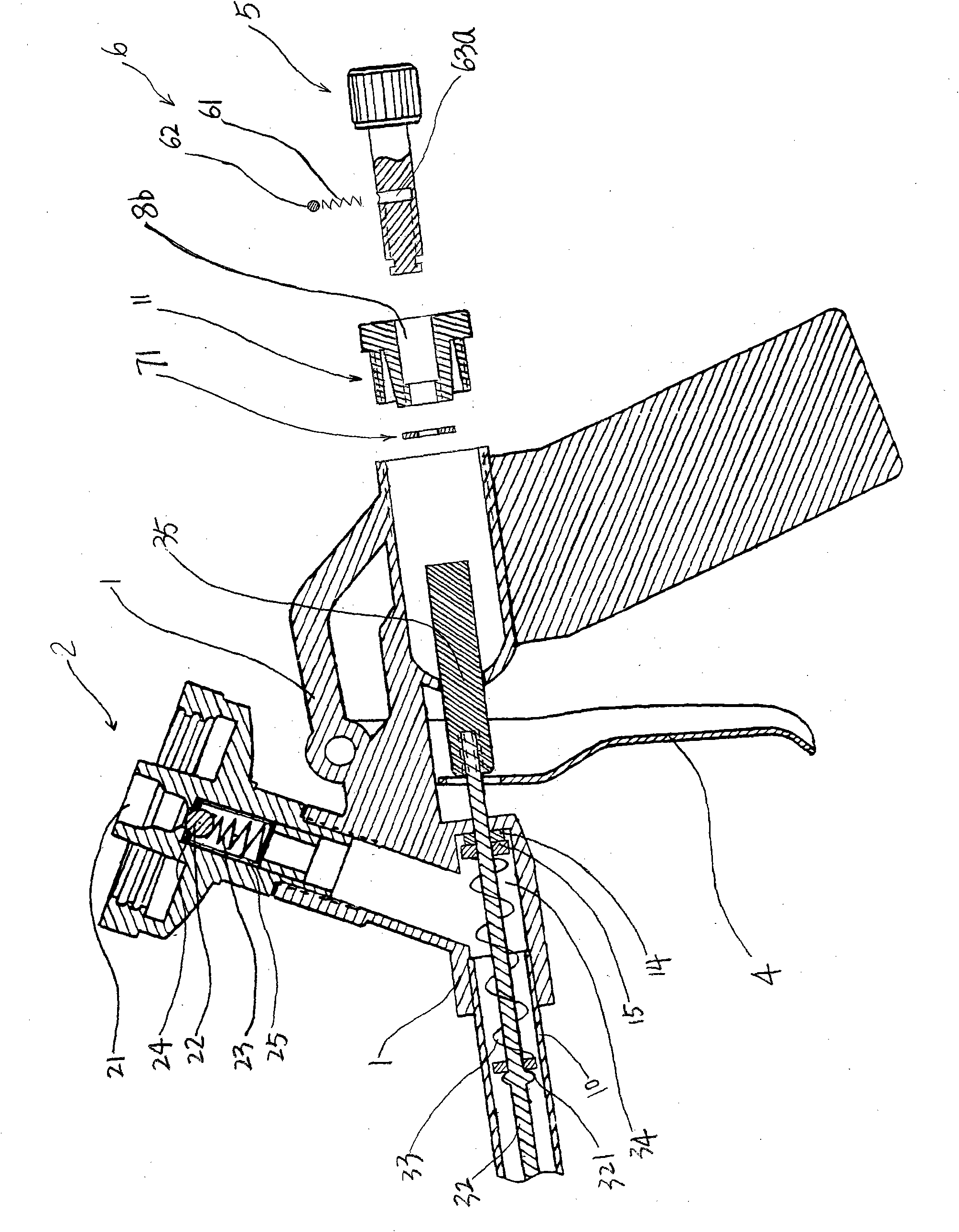

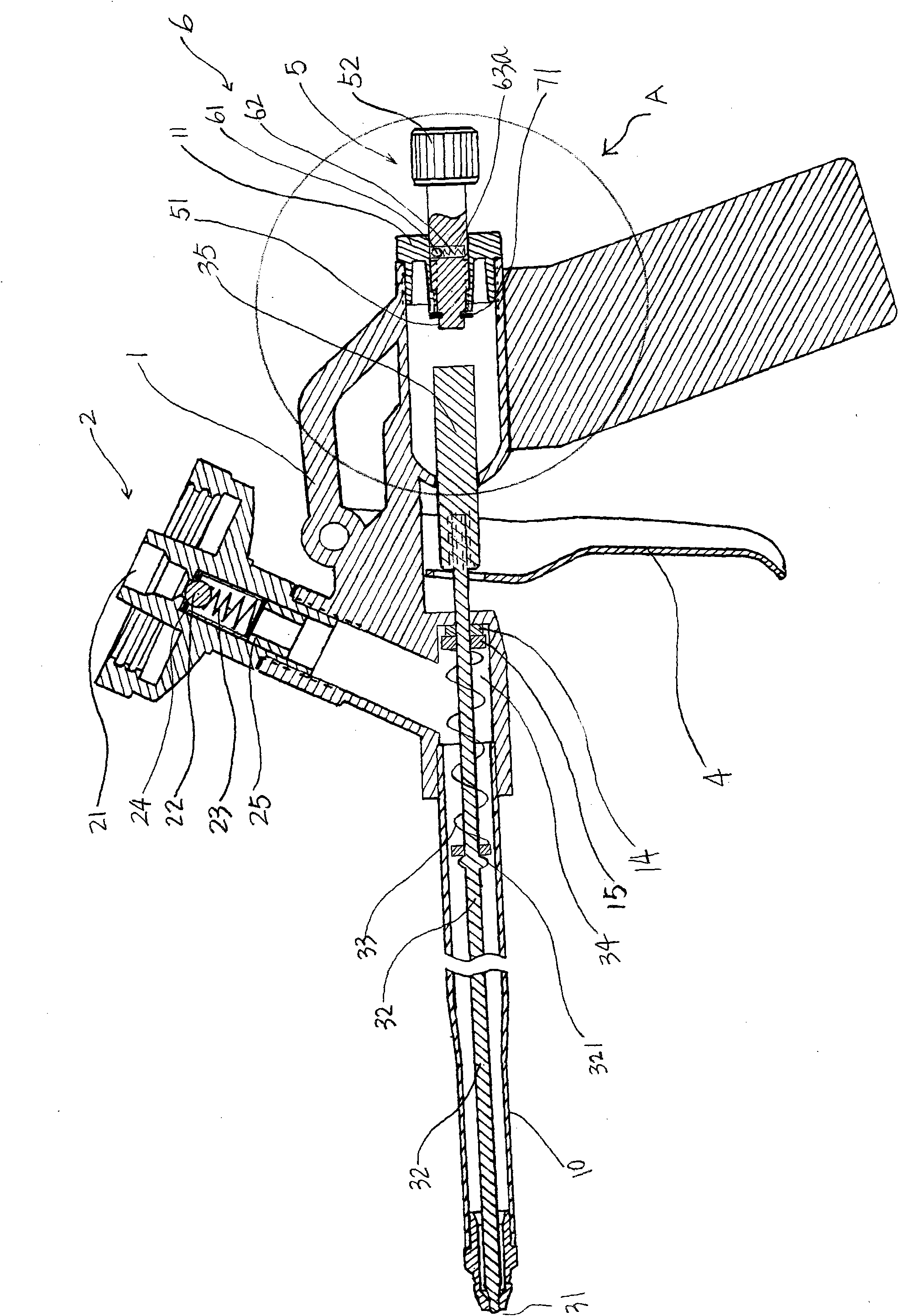

[0121] see figure 1 , figure 2 with image 3 , including gun body 1, liquid inlet valve 2, liquid outlet 31, spool 32, switch 4, return spring 33 and regulator 5 for resetting the spool, it is characterized in that: a set is used to prevent the adjustment The safety mechanism 6 for the accidental retreat of the adjustment member 5 is provided with an anti-off mechanism to prevent the safety mechanism 6 from falling off. The adjustment part is unexpectedly retreated, the adjustment telescopic movement is obvious, it is easy to grasp the adjustment and locking situation, the stability of the adjustment and locking is high, effectively prevent the safety mechanism from falling off, it is safer and more reliable, improve the construction quality and avoid the waste of foaming agent , Effectively prevent and avoid leakage or accidental injection or combustion or explosion or curing phenomenon.

[0122] Further, the safety mechanism 6 is a mechanism that utilizes frictional forc...

Embodiment 2

[0142] see Image 6 with Figure 7, a fixed sleeve 11 is provided between the adjustment member 5 and the gun body 1, and the safety mechanism 6 is arranged between the adjustment member 5 and the fixed sleeve 11, further, the fixed sleeve 11 is connected to the gun body 1 connected, a second adjustment through hole is provided on the fixed sleeve 11, and the adjustment member 5 passes through the second adjustment through hole and can generate relative displacement with the fixed sleeve 11. This structural adjustment is easy, stable and It is safe and reliable, effectively avoiding the free movement of the adjustment parts, preventing the adjustment parts from backing up unexpectedly, the adjustment telescopic movement is obvious, easy to grasp the adjustment and locking situation, the adjustment and locking are highly stable, safe and reliable, and further, it also includes the third Friction sleeve 92, the third friction sleeve 92 is at least partly arranged in the second ...

Embodiment 3

[0147] see Figure 8 with Figure 9 , a fixed sleeve 11 is provided between the adjustment member 5 and the gun body 1, and the safety mechanism 6 is arranged between the adjustment member 5 and the fixed sleeve 11, further, the fixed sleeve 11 is connected to the gun body 1 connected, a second adjustment through hole is provided on the fixed sleeve 11, the adjustment member 5 passes through the second adjustment through hole and can generate relative displacement with the fixed sleeve 11, for example, the adjustment member 5 and the The fixing sleeve 11 is threadedly connected. This structural adjustment is easy, stable, safe and reliable, which effectively avoids the phenomenon of free movement of the adjusting part, prevents the adjusting part from unexpectedly retreating, the adjustment movement is obvious, and it is easy to grasp the adjustment and locking situation. Adjustment and locking High stability, safe and reliable.

[0148] It may also include a fourth friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com