Weighing mixing control system in aerated concrete production line

An aerated concrete and control system technology, applied in the direction of control devices, etc., can solve the problems of large signal interference, waste of resources, large batching errors, etc., to achieve accurate water supply systems, eliminate waste of resources, and uniform delivery of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

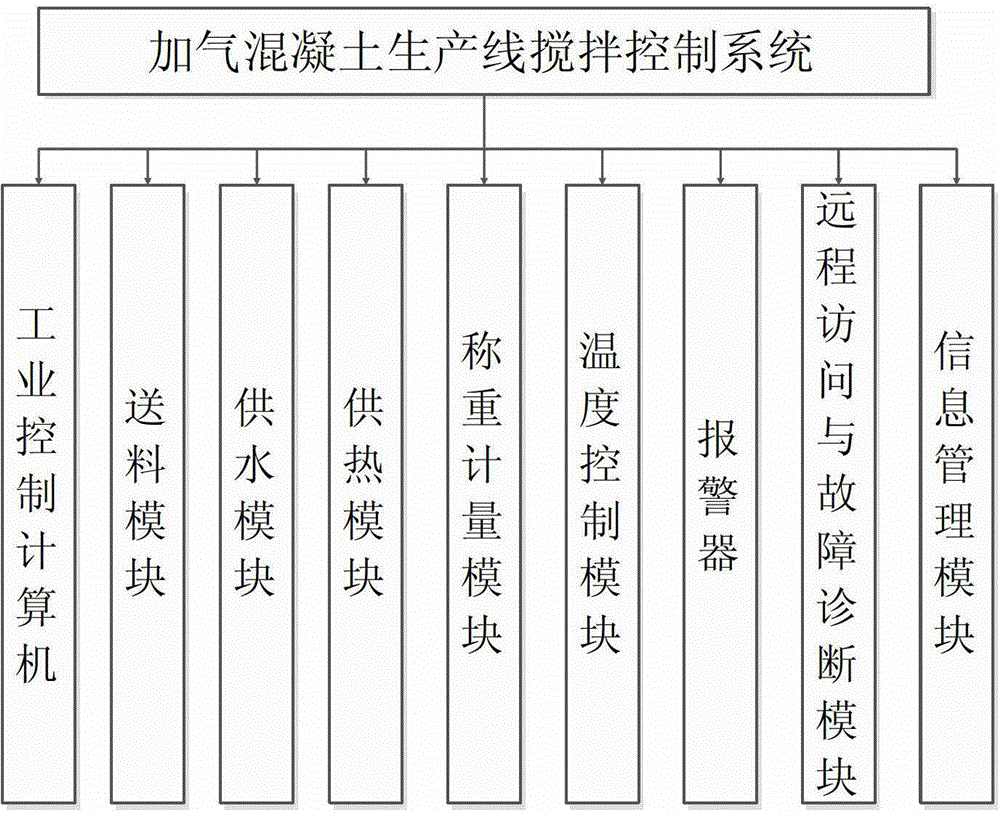

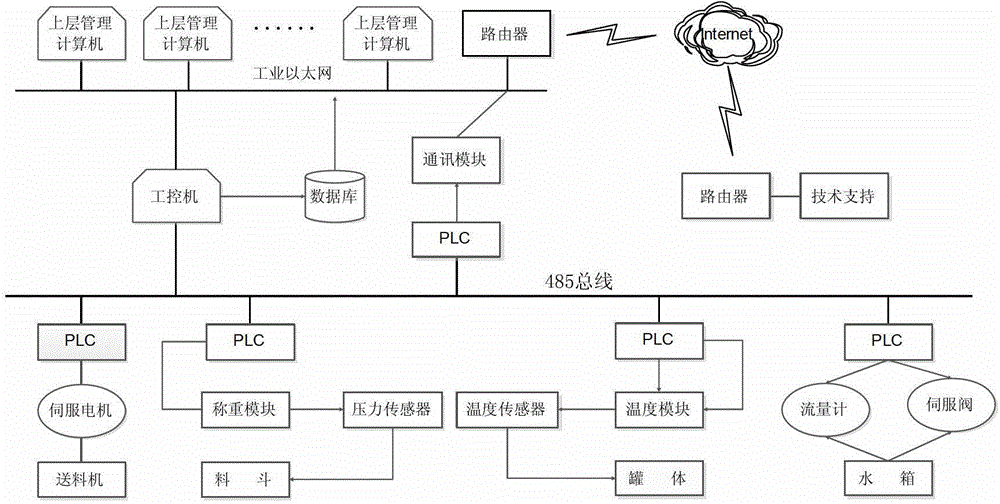

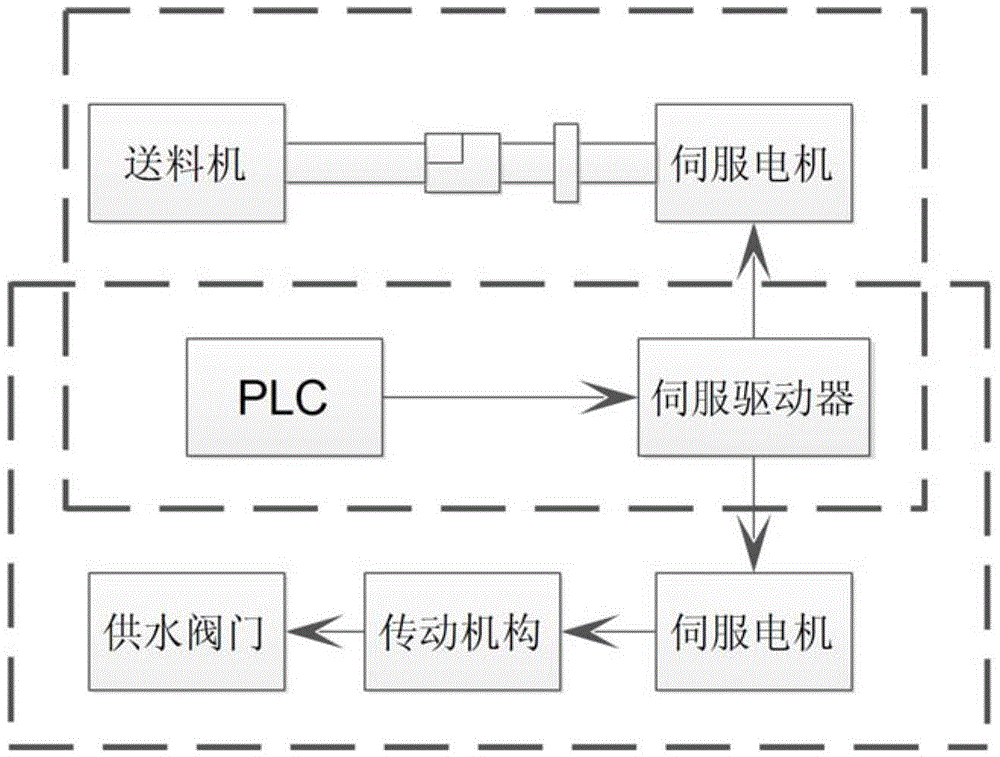

[0018] The weighing and stirring control system of the aerated concrete production line of the present invention includes: a feeding module, a water supply module, a heating module, a weighing and measuring module, a temperature control module, an alarm, a remote fault diagnosis module and an information management module; the hardware includes: industrial control Computer, upper management computer, external database, pressure sensor, temperature sensor, Siemens PLC, Siemens weighing module, Siemens temperature module, Siemens communication module, flow meter, servo motor and supporting equipment, including ADSL router, GPRS router, switchboard communication equipment. The feeding module, weighing and measuring module, temperature control module, and water supply module are connected to the industrial control computer through the RS-485 bus; the industrial control computer and the upper management computer form a computer network through the industrial Ethernet to manage the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com