Device for conveying fuel

A fuel and guide device technology is applied in the field of fuel conveying devices to achieve the effect of simplifying installation and improving functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

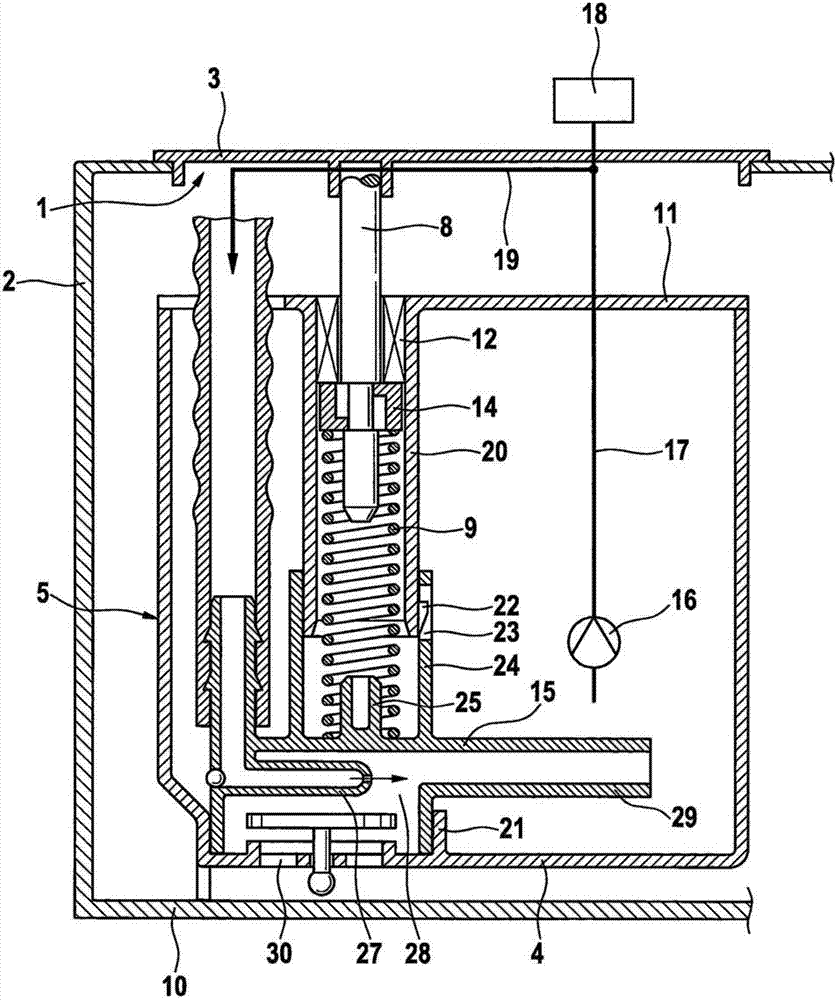

[0015] The drawing shows a simplified sectional illustration of a device according to the invention for delivering fuel, which is also referred to as a fuel delivery module.

[0016] The device for conveying fuel has a tank flange 3 closing off a tank opening 1 of a fuel tank 2 and a storage tank 5 with a tank bottom 4 . The tank flange 3 and the storage tank 5 are connected to one another via at least one guide rod 8 , wherein the storage tank 5 can be adjusted relative to the tank flange 3 along the guide rod 8 . The storage tank 5 is pressed by a spring element 9 , for example a helical compression spring, away from the tank flange 3 , so that the storage tank 5 always rests with its bottom 4 on the bottom 10 of the fuel tank 2 . The storage tank 5 has a cover 11 which is fixedly connected to the storage tank 5 and on which a bearing 12 is respectively arranged for guiding the at least one guide rod 8 . The guide rod 8 is free to move in its bearing 12 in the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com