Filter plate component in multifunctional filter dryer

A filter dryer and multi-functional technology, which is applied in the mechanical field, can solve the problems of strengthening the filter plate assembly, deformation and failure of the filter plate assembly, etc., and achieve the effect of prolonging the service life, preventing deformation, and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

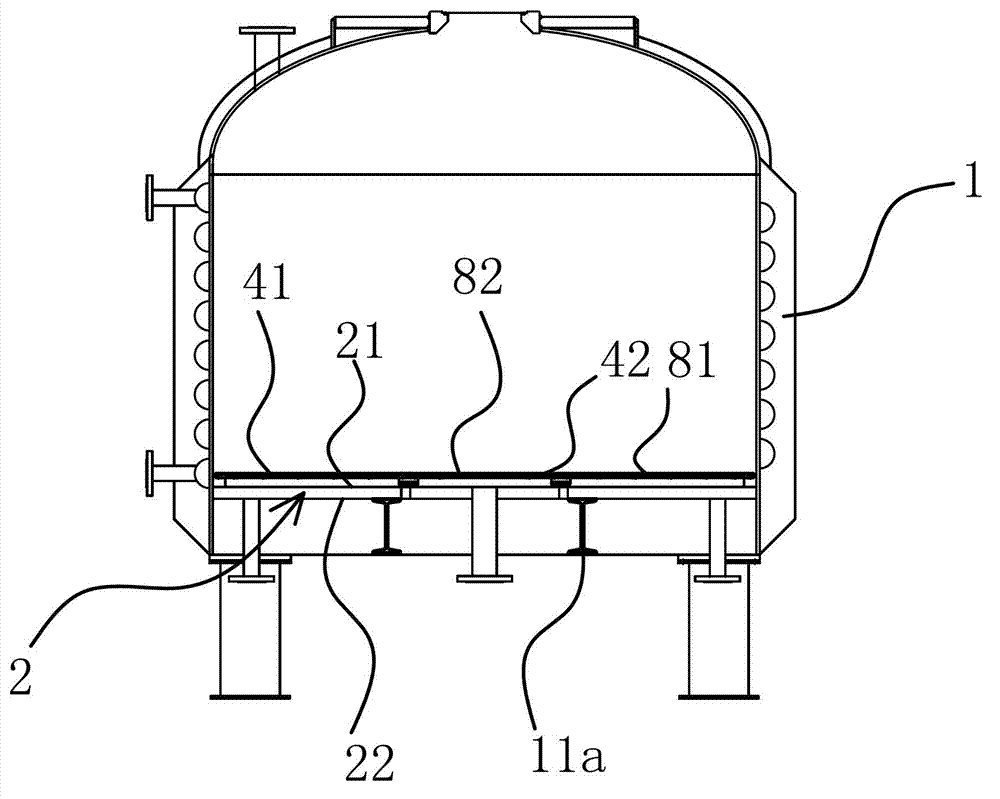

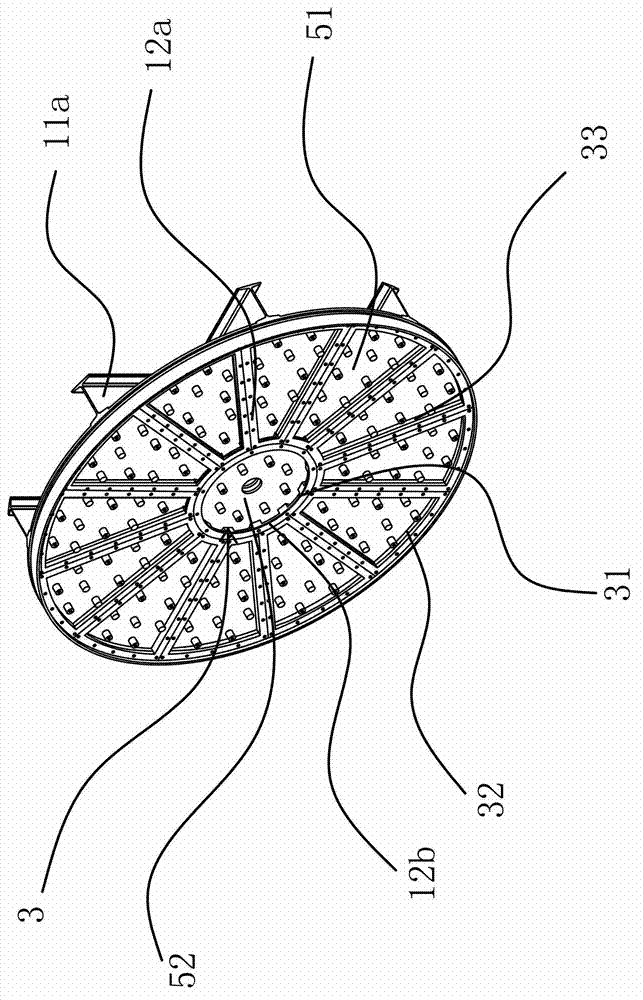

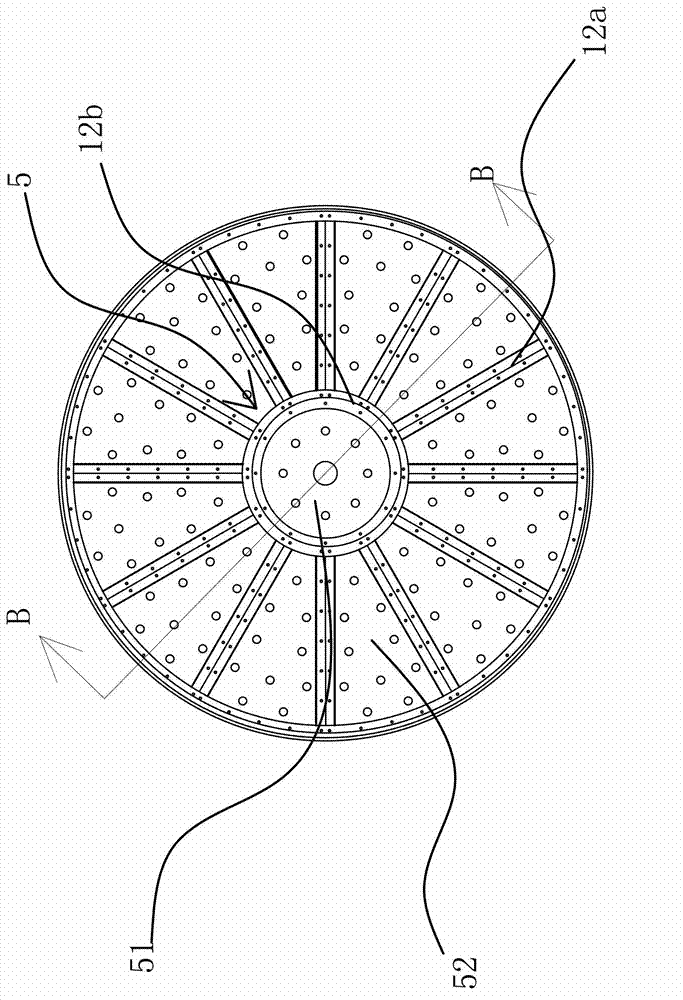

[0035] A filter plate assembly in a multifunctional filter dryer, the dryer includes a tank body 1 with a cavity inside and an open lower end, the filter plate assembly is arranged at the lower end of the tank body 1 and closes the opening of the tank body 1, the The filter plate assembly includes a bottom plate 2, a support frame 3 and several sintered plates 4. The shape of the bottom plate 2 matches the shape of the lower end section of the tank body 1. The support frame 3 is welded to the bottom plate 2. The support frame 3 has several mounting parts 5. The sintered plate 4 Welded in the installation part 5 so that the sintered plate 4 and the support frame 3 cover the bottom of the entire tank body 1, the support frame 3 includes an inner flange 31, an outer flange 32 and radially connected inner flange 31 and outer flange 32 Between the square steel 33, the mounting part 5 is surrounded by the inner flange 31, the outer flange 32 and the square steel 33. The traditional ...

Embodiment 2

[0042] The content of this embodiment is roughly the same as that of Embodiment 1, except that the positioning structure 9 includes several support plates 94 welded between the lower base plate 22 and the upper base plate 21, and the positioning structure 9 also includes several support plates welded on the upper base plate. 21 and the support plate two 95 between the fan-shaped filter plate 81 and the circular filter plate 82, the plate surface of the support plate one 94 is provided with some and through holes 96, and the support plate one 94 connects both the upper base plate 21 and the lower base plate 22 The support plate 2 95 securely connects the upper bottom plate 21 with the fan-shaped filter plate 81 and the circular filter plate 82 , and the through hole 96 provided on the support plate 1 94 facilitates the circulation of the heating medium in the heating chamber 10 .

[0043] The principle of the present invention is: in order to prevent the filter plate assembly fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com