Groove bottom surface rolling tool

A surface rolling and tooling technology, which is applied in the field of groove bottom surface rolling tools, can solve the problem that the roller cannot be submerged in the sealing groove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

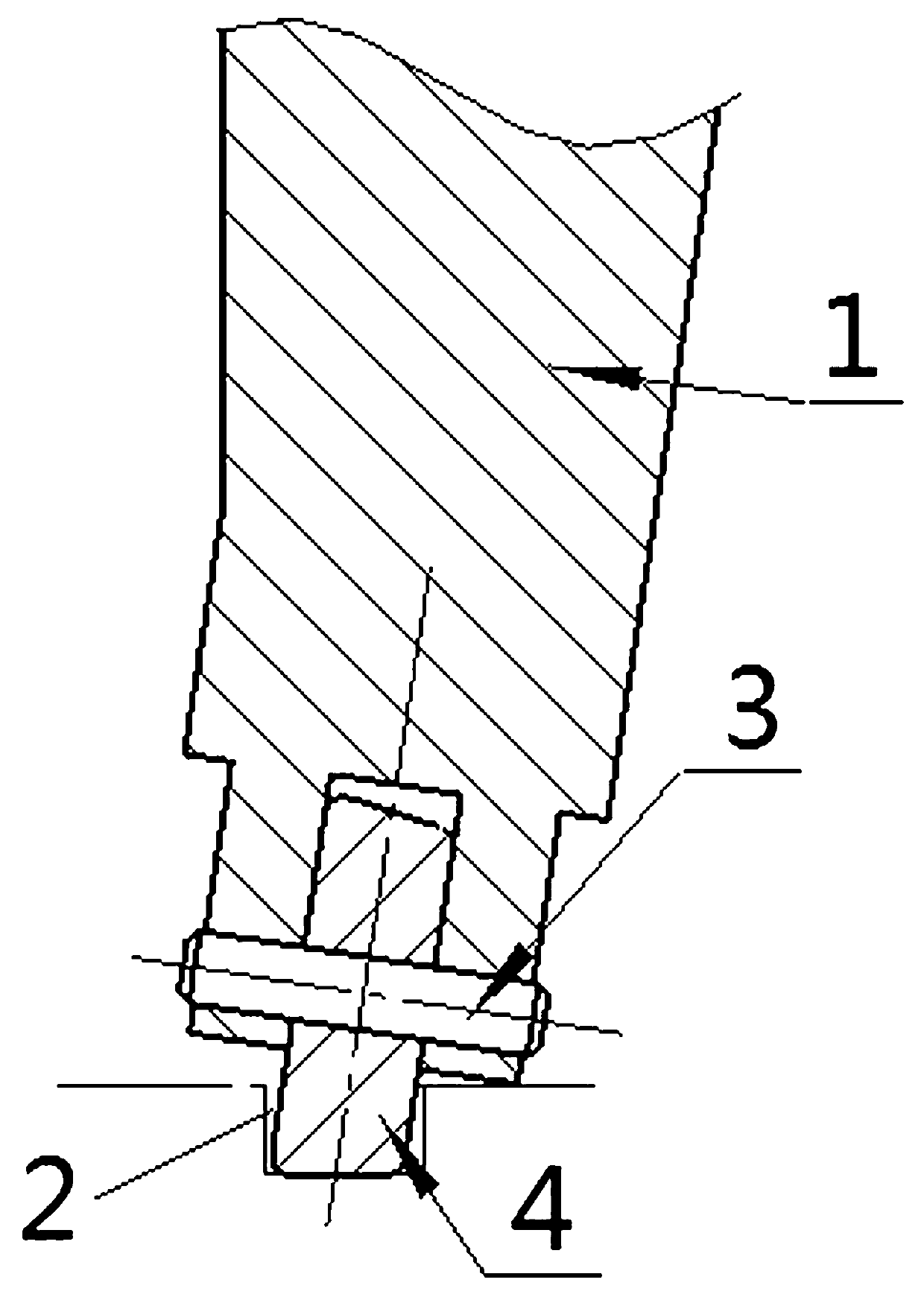

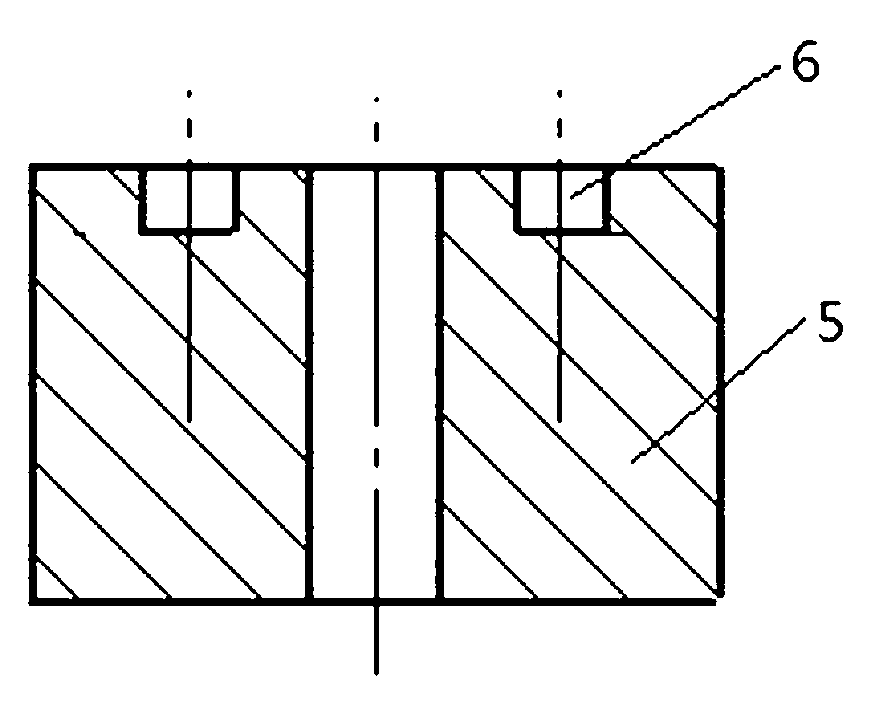

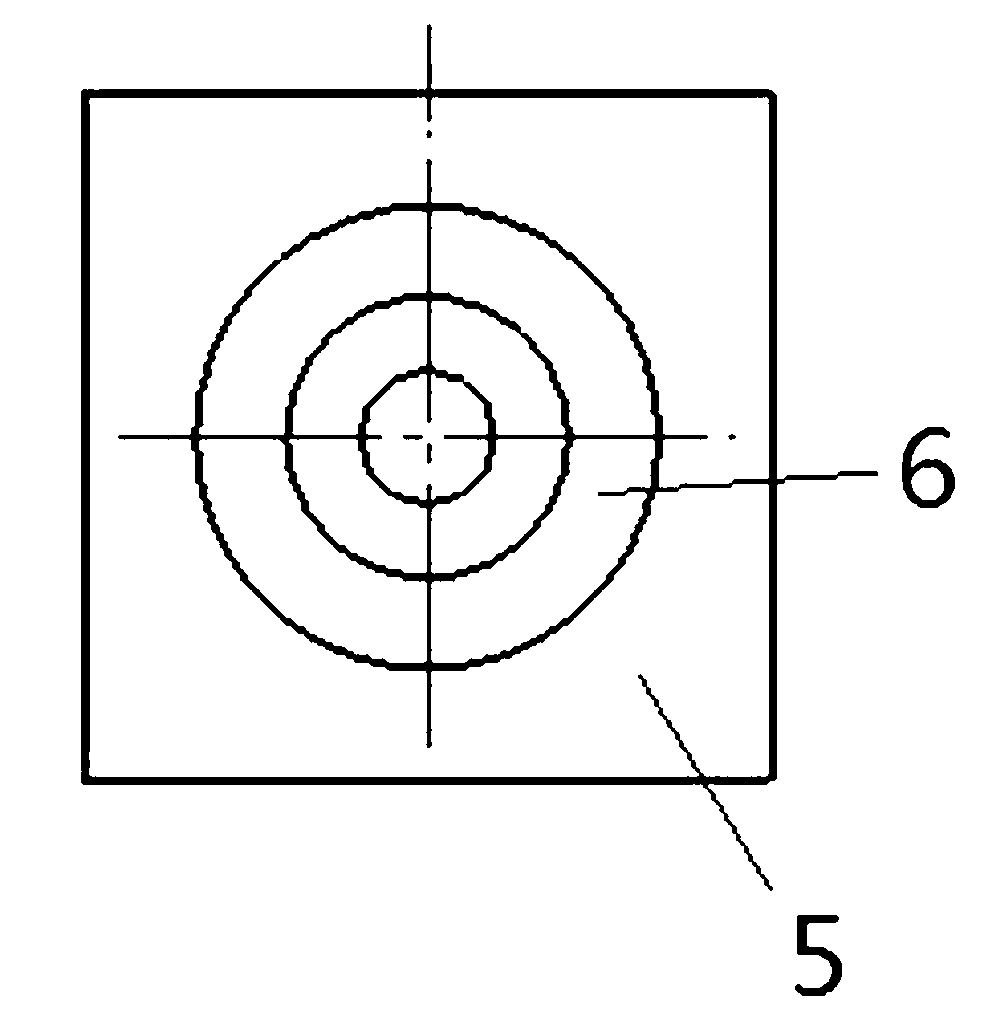

[0031] The structure of the sealing groove that needs to be rolled is as follows: Figure 2~3 As shown: the sealing groove 6 is opened on the end surface of the workpiece 5, and the groove width of the sealing groove 6 is small, and the groove bottom surface of the sealing groove 6 cannot be rolled with conventional rolling tools.

[0032] An embodiment of a groove bottom surface rolling tool is Figure 4~17Shown: including the knife rest, the knife rest includes the knife body 7 and the side support plate 8 and the stop piece 9 fixed on the lower end of the knife body 7 from left to right through the fixed connection structure. The fixed connection structure includes realizing the side support plate 8 and the stop piece respectively Sheet 9 and cutter body 7 positioning pins 12 and connecting screws 11 for positioning assembly and fixed assembly, side support plate 8, retaining plate 9 and cutter body 7 are all provided with positioning holes that are matched with positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com