Flexible support micro-vibration testing device for simulating whole satellite

A flexible support and testing device technology, used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of complex loading and unloading, no coupling effect of micro-vibration source disturbance characteristics, etc., to achieve a wide range of adaptability and save development Expenses, the effect of meeting the measurement needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

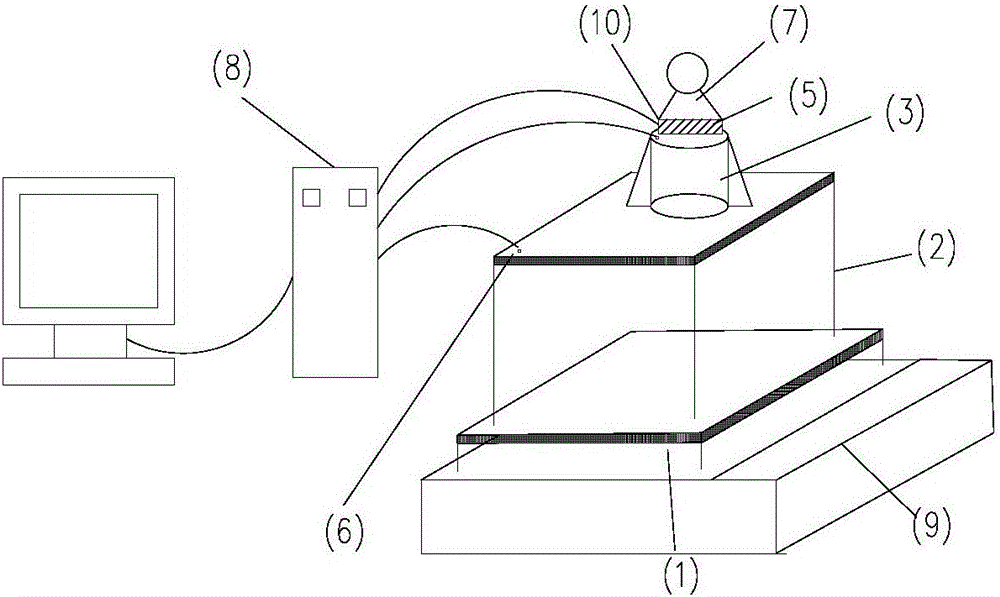

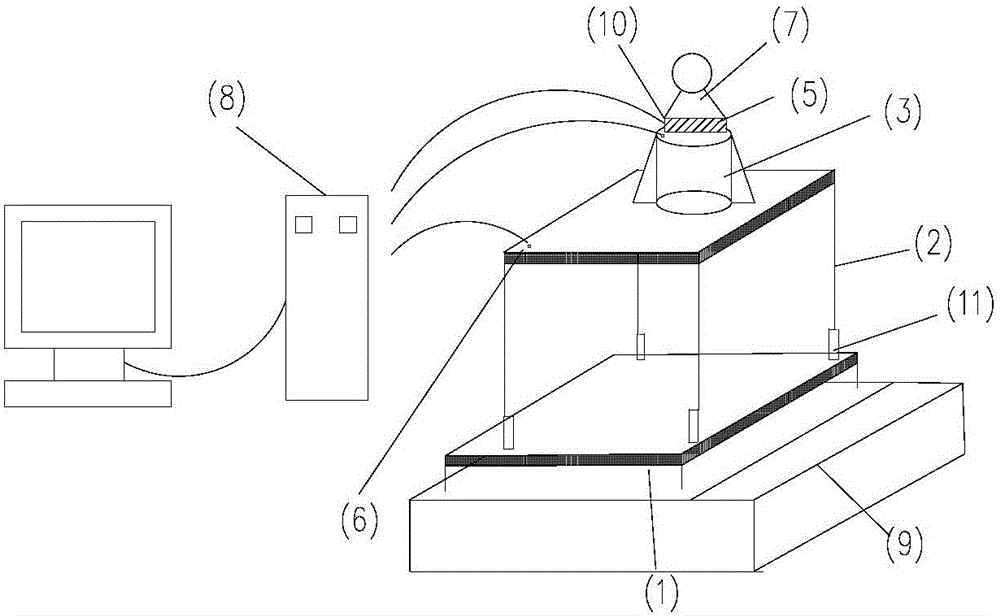

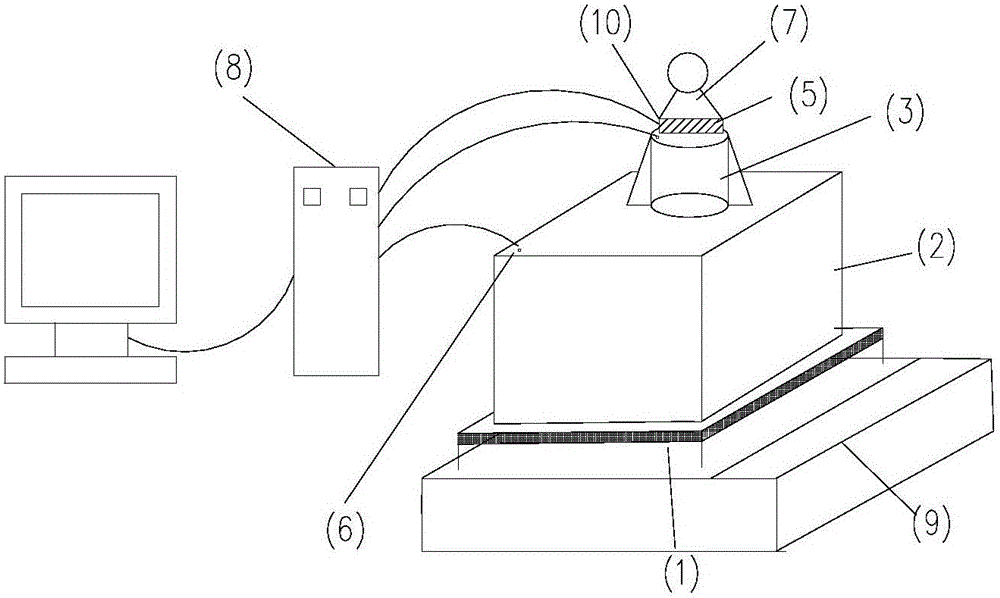

[0043] A flexible support micro-vibration test device for simulating a satellite whole star, which includes: a support structure 3, a six-component force sensor 5, an acceleration sensor 6, a data acquisition and processing system 8 and a transfer support 10, and the test object is a whole star Analog 7;

[0044] The upper part of the bracket support structure 3 is fixed with the six-component force sensor 5 through the interface, the six-component force sensor 5 is fixed with the whole star simulation part 7 through the adapter support 10, the acceleration sensor 6 is pasted on the bracket support structure 3, and the data acquisition and processing system 8 are respectively connected with the six-component force sensor 5 and the acceleration sensor 6;

[0045] Such as Figure 6 As shown, the flexible support micro-vibration testing device also includes a rigid platform 9; several ground rails are arranged on the rigid platform 9, and the bracket support structure 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com