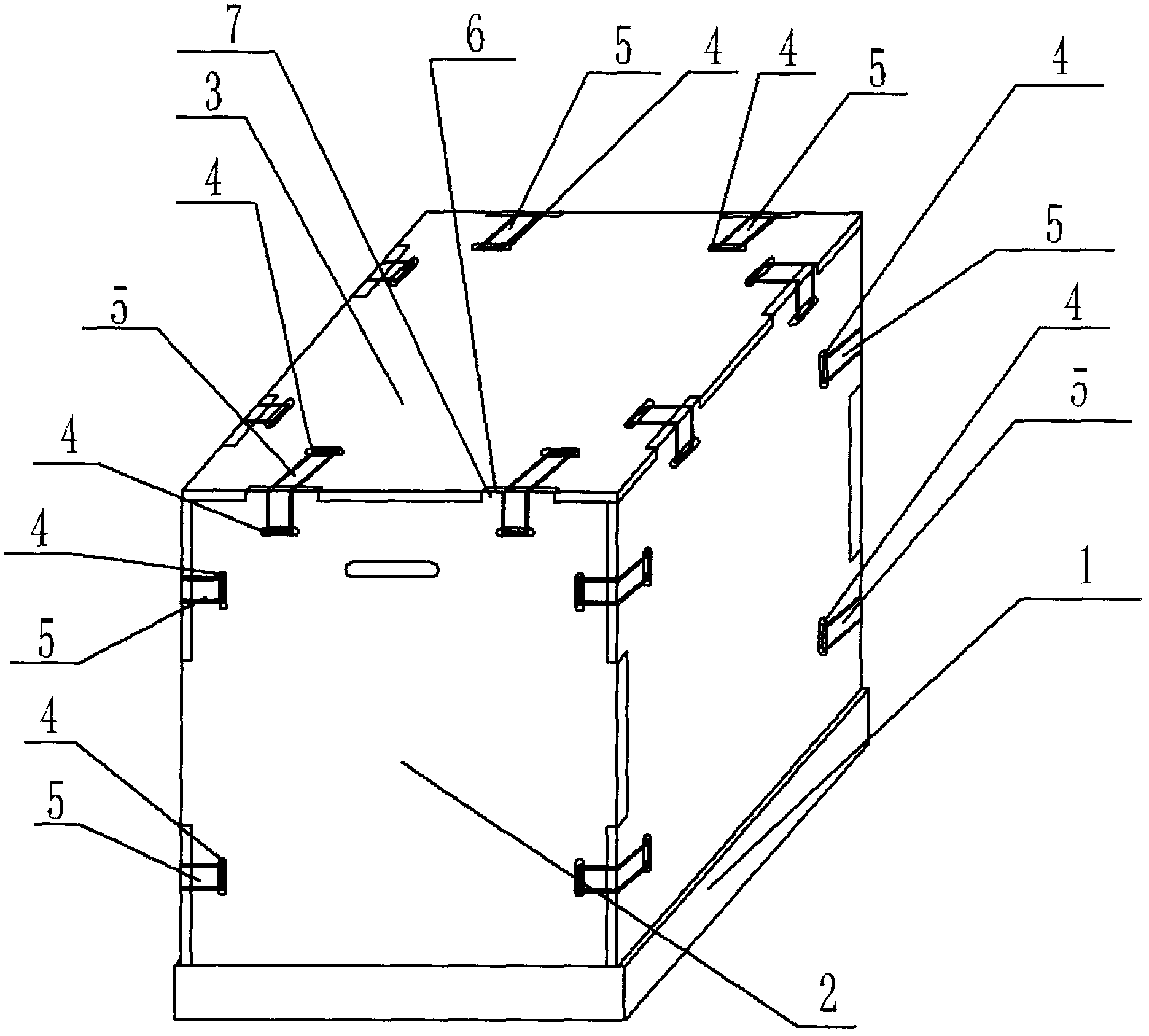

Packing box structure

A packing box and side panel technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of wasting wood, destroying the natural environment, increasing production costs, etc., and achieve the effect of reducing waste and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

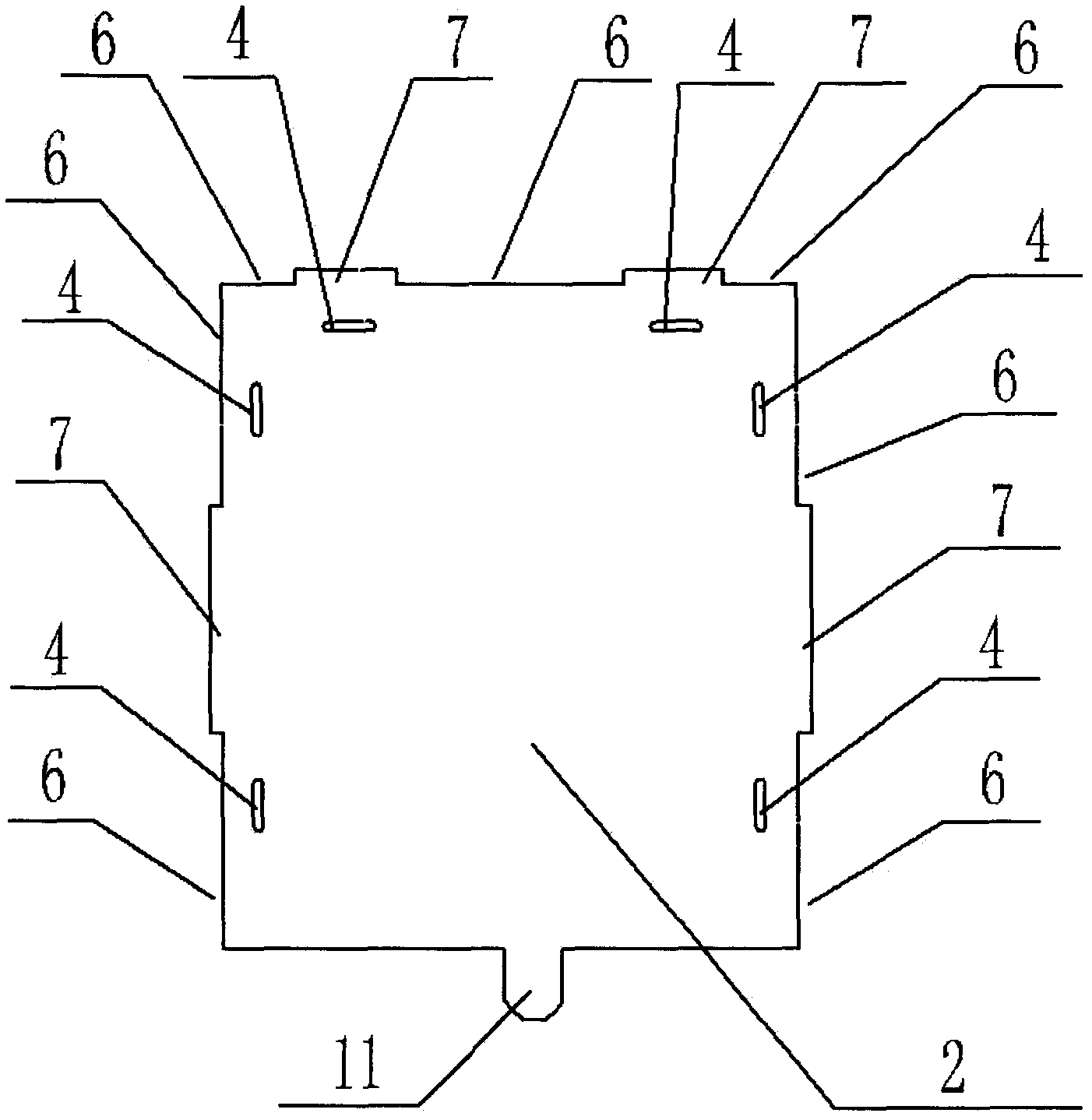

[0016] Example one, see figure 2 , image 3 with Figure 5 , The base 1 is provided with a bottom plate 8, a T-shaped groove 9 is provided on the side of the bottom plate 8, a pair of opposite side plates 2 are provided with a T-shaped connecting rod 10 that matches the T-shaped groove 9, and the T-shaped connecting rod 10 is inserted into the T The groove 9 moves to the outside of the bottom plate to realize the stable and detachable clamping connection between the side plate 2 and the bottom plate 8. The other pair of opposite side plates 2 are provided with positioning rods 11 that cooperate with the T-shaped groove 9 to ensure the side plates. 2. Positioning.

Embodiment 2

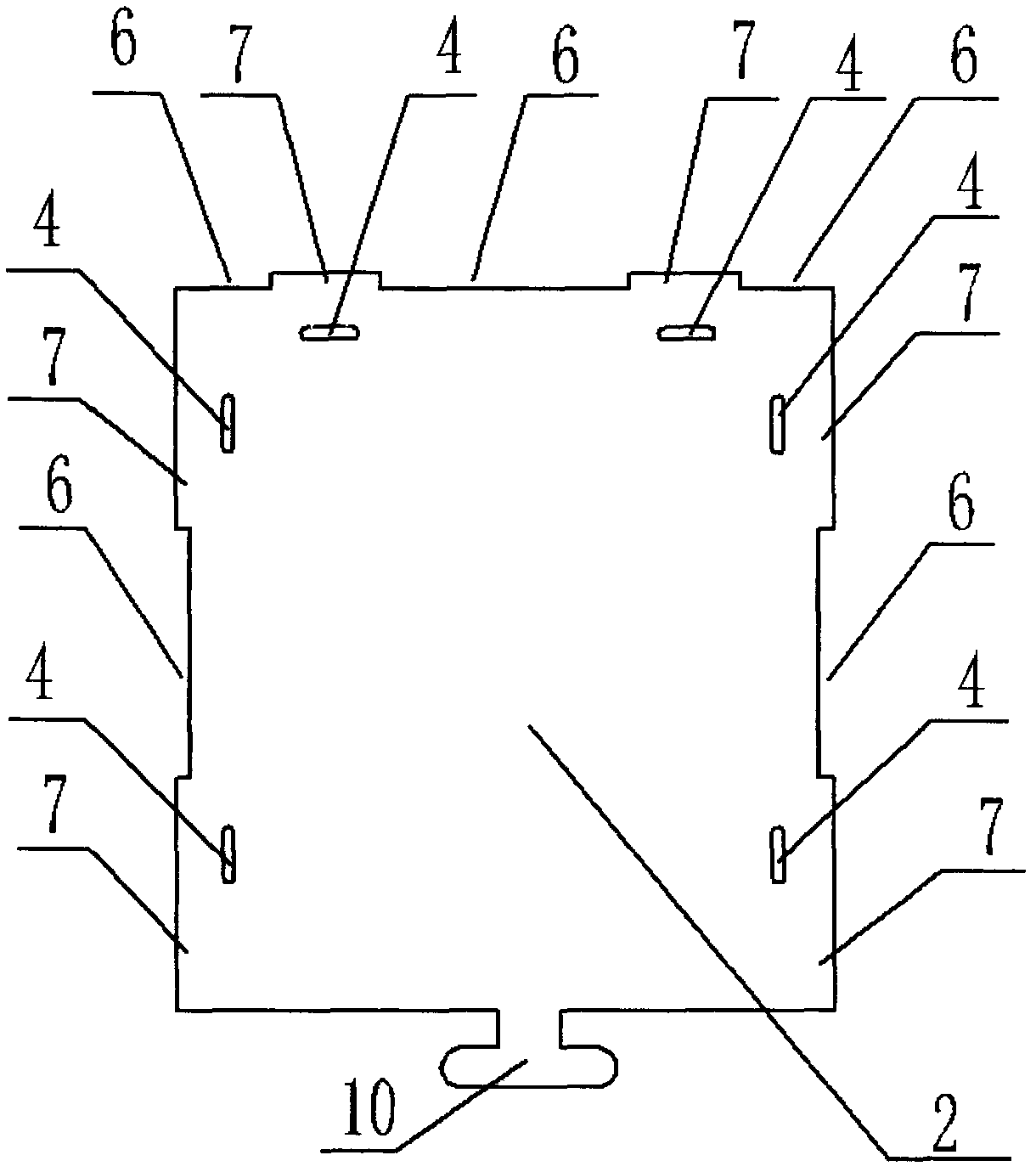

[0017] Example two, see figure 2 , Image 6 with Figure 7 , The base 1 is provided with a bottom plate 8, a positioning groove 13 is provided on the side of the bottom plate 8, a positioning rod 11 matching the positioning groove 13 is provided on the side plate 2, and a pair of positioning rods 11 are provided with a positioning groove 13 The matching positioning circlip 12, after the positioning circlip 12 is inserted into the positioning slot 13, realizes the stable and detachable snap connection between the side plate 2 and the bottom plate 8. In order to facilitate processing and the versatility of the positioning groove in the structure of the positioning groove, the positioning groove in the second embodiment can also be added to the T-shaped groove in the first embodiment to realize the versatility of the positioning groove and the unity of processing.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap