Method for determination of reversal time of sheet glass melting furnace

A technology for flat glass and determination method, applied in glass production, glass furnace equipment, glass manufacturing equipment and other directions, can solve problems such as reducing energy saving effect, and achieve the effect of improving energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

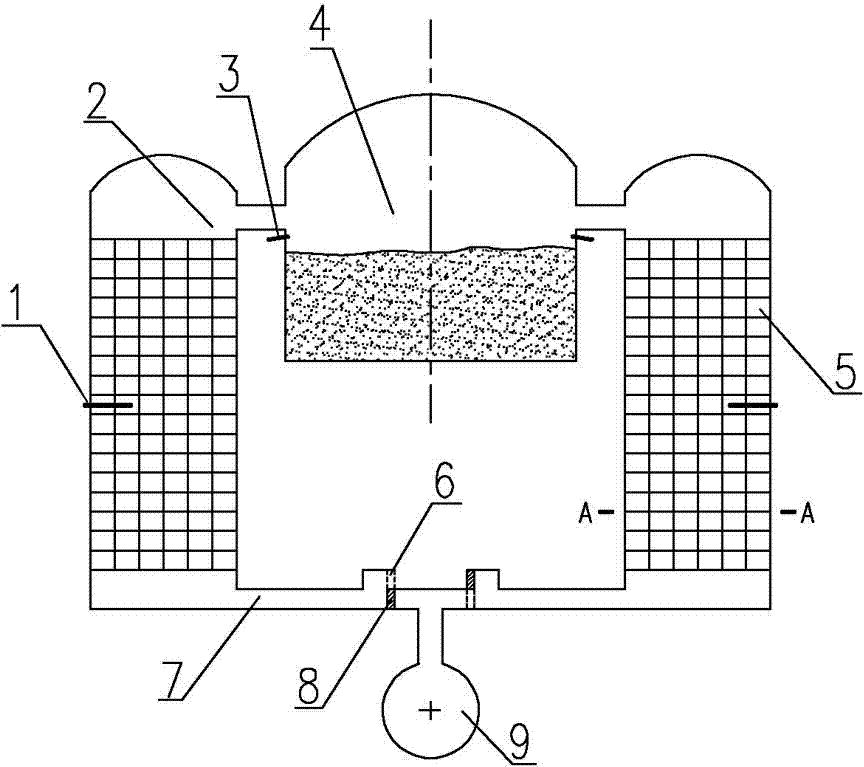

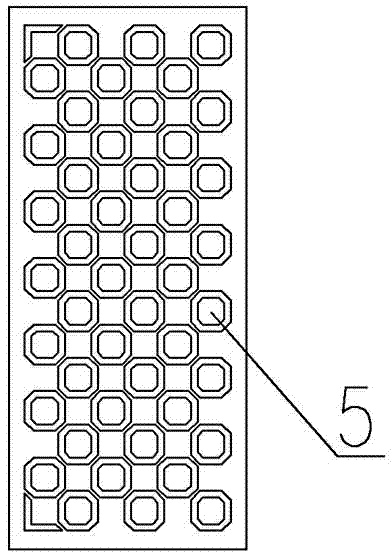

[0018] Such as figure 1 with figure 2 As shown, the glass melting furnace in the method for determining the fire exchange time of the plate glass melting furnace of the present invention includes a glass melting furnace 4, the inner walls of both sides of the melting furnace 4 are provided with symmetrical spray guns 3, and the outer side of the melting furnace 4 is symmetrically provided with a heat storage chamber and a heat storage chamber One end of the regenerator is the flue one 2 communicating with the interior of the melting furnace 4, and the other end of the regenerator is flue two 7. The middle part of the regenerator is filled with cylindrical checker bricks 5, and each side flue two 7 has an air inlet 6 at the outlet. The two air inlets 6 are arranged symmetrically, and each air inlet 6 is provided with a movable shutter 8 which forms a half-closed and half-open state on the air inlet 6, and half of the two air inlets 6 pass through T The arc-shaped channel is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com