Obtaining method of large deformation pipe line steel double phase structure

A dual-phase microstructure and acquisition method technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problem of duplex microstructure photos and stress-strain curves without providing manufacturing process plans, large-deformation duplex microstructure, production methods and The process has not been publicly reported and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for obtaining a dual-phase structure of X70 steel grade large deformation pipeline steel, comprising the following steps:

[0028] Step 1: Determine the chemical composition of the steel (as shown in the table below): the units of the following parameters are mass percentages

[0029]

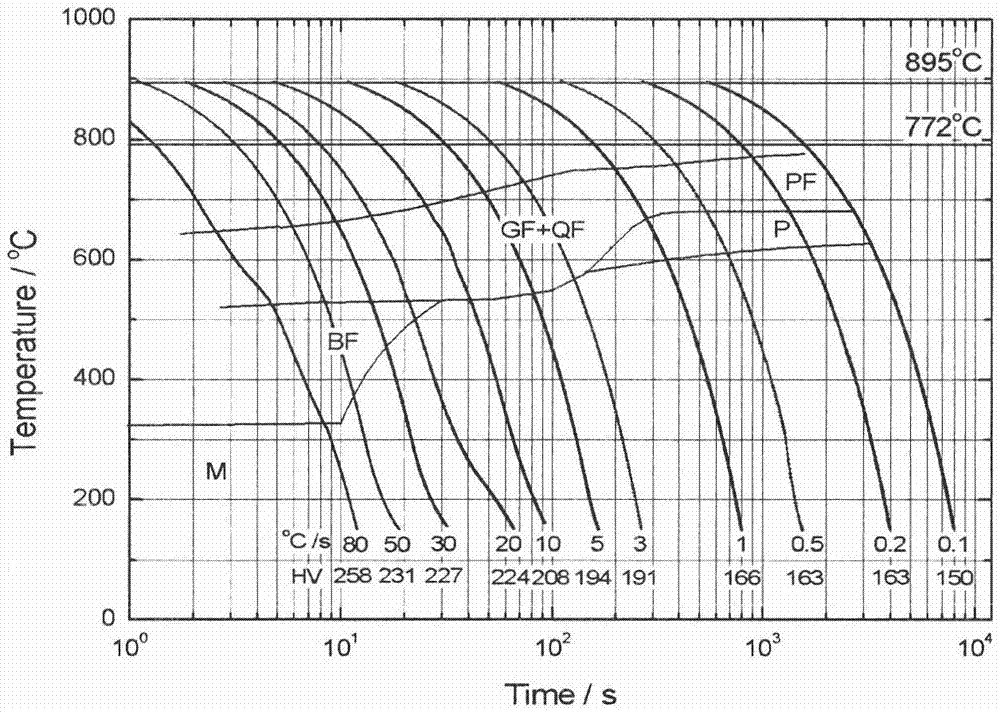

[0030] Step 2: The continuous cooling transformation curve of steel, such as figure 1 The CCT curve shown;

[0031] Step 3: According to the continuous cooling transformation curve, the cooling rate of the moderately accelerated cooling for obtaining the dual-phase structure of the steel is determined to be in the range of 37-46°C / s;

[0032] Step 4, determining that the range of the phase transition point corresponding to the cooling rate range is 663-660°C;

[0033] Step 5. Determine the starting cooling temperature of the steel as 680° C. and the cooling rate as 40° C. / s according to the determined phase transition point and cooling rate range;

[0034] Step six, adopti...

Embodiment 2

[0046] A method for obtaining a dual-phase structure of X80 steel grade large deformation pipeline steel, comprising the following steps:

[0047] Step 1: Determine the chemical composition of the steel (as shown in the table below): the units of the following parameters are mass percentages

[0048]

[0049] Step 2: The continuous cooling transformation curve of steel, such as Figure 4 shown;

[0050] Step 3: According to the continuous cooling transformation curve, the cooling rate of the moderately accelerated cooling for obtaining the dual-phase structure of the steel is determined to be in the range of 45-55°C / s;

[0051] Step 4, determine the range of the phase transition point corresponding to the cooling rate range (700-708°C);

[0052] Step 5. Determine the starting cooling temperature of the steel as 720° C. and the cooling rate as 50° C. / s according to the determined phase transition point and cooling rate range;

[0053] Step six, adopting the moderately acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com