Method for rapid detection of ventilation performance of filter rods for high air permeability formed cigarettes

A filter rod and forming paper technology, which is applied in the fields of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as the influence of cigarette product quality, tar fluctuation of cigarettes, hidden dangers of cigarette product quality, etc. Accurate and effective quality evaluation, good accuracy and repeatability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] The method for quickly detecting the ventilation performance of a filter rod for high air permeability formed cigarettes provided by the present invention comprises the following steps:

[0023] (1), determine the closed suction resistance, circumference, length, hardness index processing parameters of the filter rod;

[0024] (2), using forming papers with different air permeability indexes to make test filter rod samples;

[0025] (3) Use the Borgwatt KC3 instrument to test the open suction resistance of different test filter rod samples;

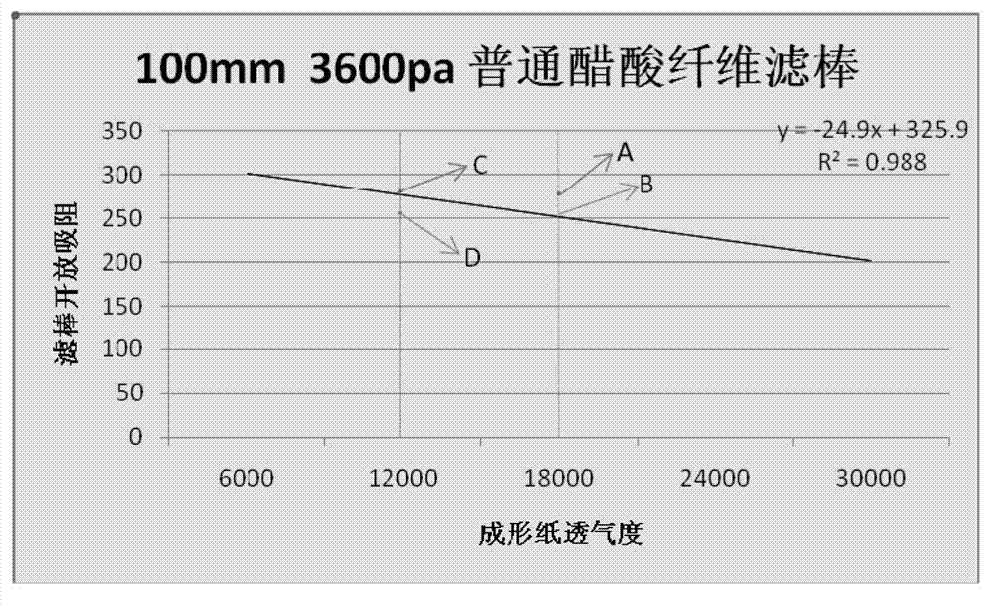

[0026] (4), through the open suction resistance of step (3) gained, make a straight line graph to the air permeability of the forming paper;

[0027] (5) Test the open suction resistance of the filter rod to be tested, and judge its ventilation performance by the size of the open suction resistance value. If the open suction r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com