Testing device for simulating spontaneous combustion and fire extinguishment processes of coal

A test device, a technology for spontaneous combustion of coal, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of large testing workload, difficult promotion and application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

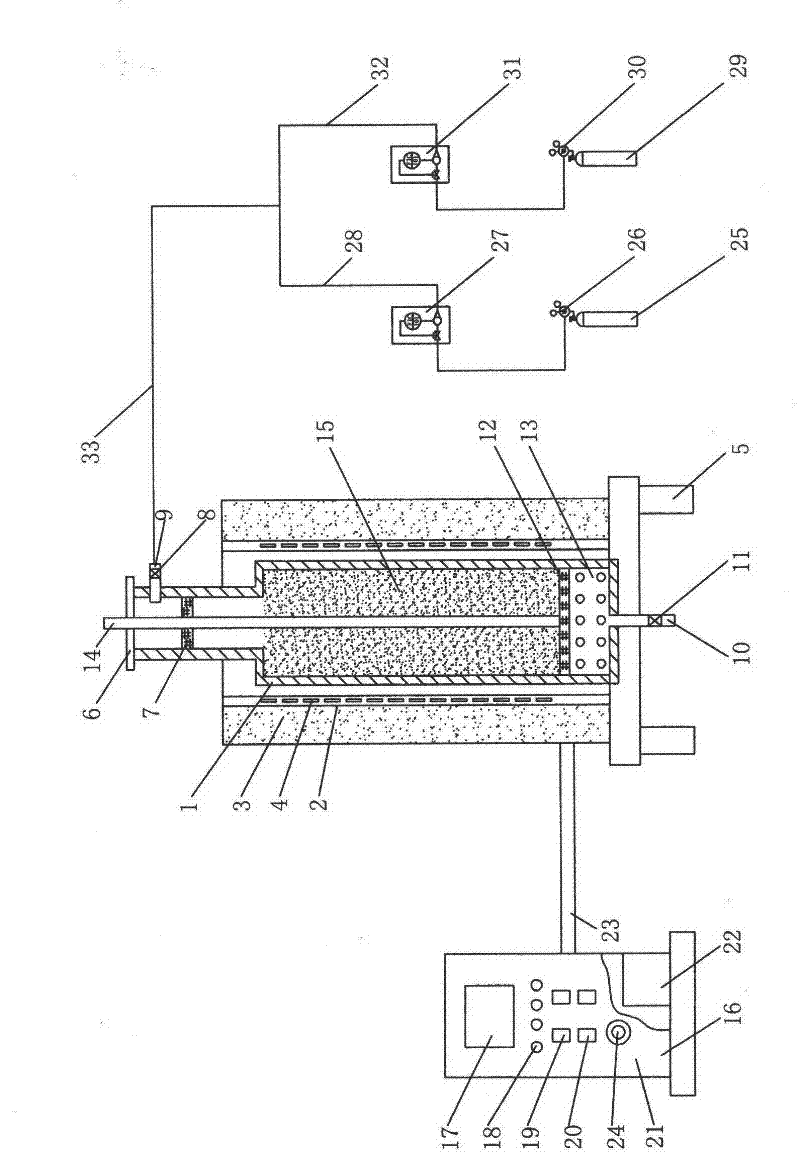

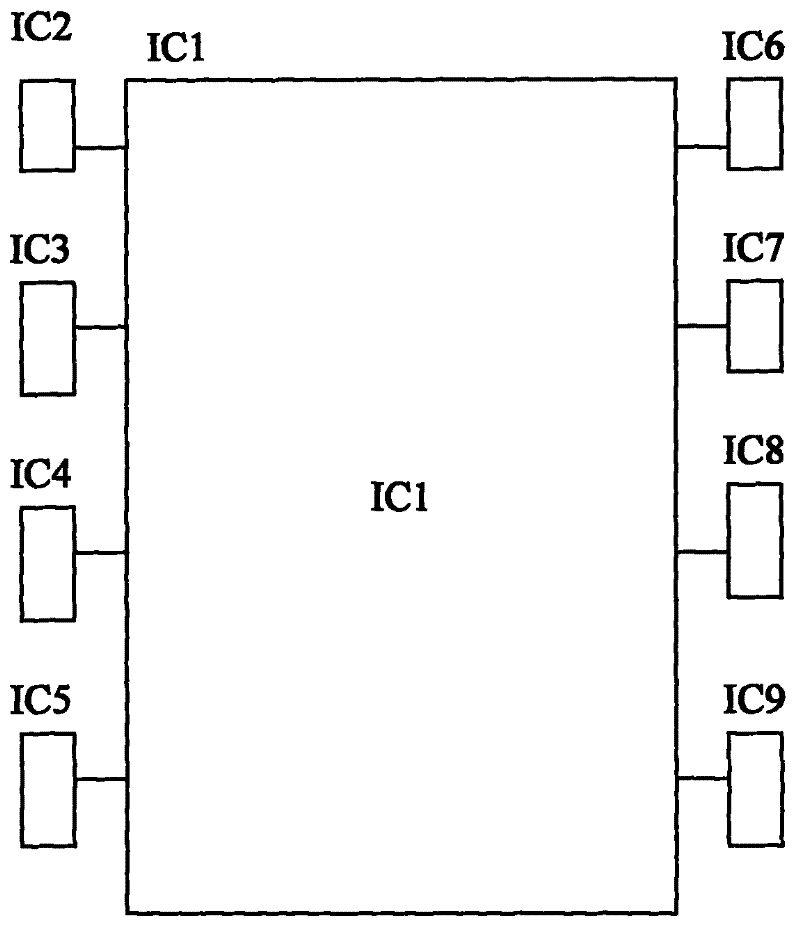

Method used

Image

Examples

Embodiment 1

[0026] The simulated coal spontaneous combustion and fire extinguishing test methods are as follows:

[0027] 1), sample preparation

[0028] Take a fresh coal sample for crushing, sieve through a 60-80 mesh screen, dry the coal sample, and then loosely put it into the reactor;

[0029] 2), ventilation

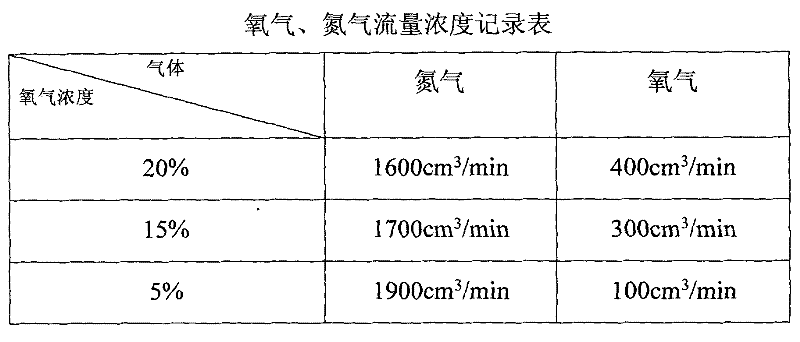

[0030] The oxygen cylinder and the nitrogen cylinder are fed into the kettle at the same time, and the flow rate of oxygen and nitrogen is observed by adjusting the ratio of the mixed gas of oxygen and nitrogen, that is, the concentration of oxygen in the mixed gas. The total flow rate is 2000cm 3 / min, and recorded in Chart 3;

[0031] 3), temperature control

[0032] ① Regulate the temperature in the reaction kettle through the temperature controller on the electric control box, so as to control the temperature of the sample coal in the reaction kettle;

[0033] ②Adjust the heating frequency of 5°C / min, 10°C / min, 20°C / min, and adjust to a maximum temperature of 1100°C; ...

Embodiment 2

[0039] 1), ventilation

[0040] When the coal temperature in the reaction kettle rose to 200°C, turn off the oxygen cylinder to stop the oxygen supply, then connect the nitrogen cylinder, and adjust the nitrogen flow meter to the same value as the flow rate of the mixed gas in Example 1, 2000cm 3 / min;

[0041] 2), turn off the temperature controller

[0042] When the temperature in the reactor rises to 200°C, close the reactor warmer, stop heating, and then let the reactor cool down to normal temperature 25°C;

[0043] 3. Temperature and index gas monitoring

[0044] Reduce the temperature in the reactor by closing the temperature controller, and use a gas chromatograph to detect the gas sample at the outlet pipe. The coal temperature in the reactor is lowered by 10°C, and the gas components and their concentrations are detected and recorded in Chart 5;

[0045] 4), result analysis

[0046] Through the detection of the index gas at different temperatures, it is concluded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com