Shortener locking mechanism

A locking mechanism and dough mixer technology, applied in the structural parts of mixing/kneading machinery, household appliances, applications, etc., can solve the problems of loose hinge structure, large vibration, affecting the service life of equipment, etc., and achieve fast connection. Convenient, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

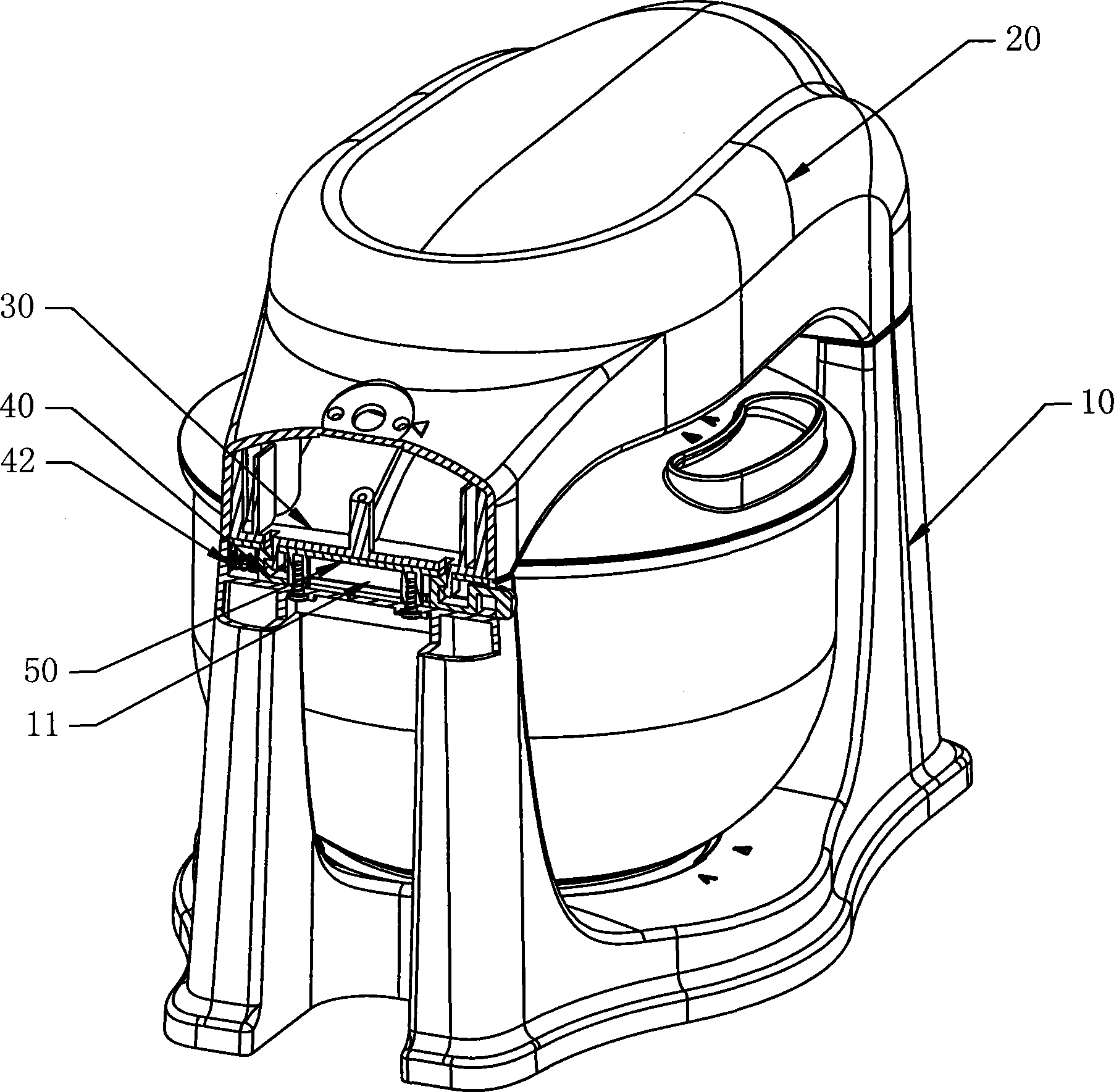

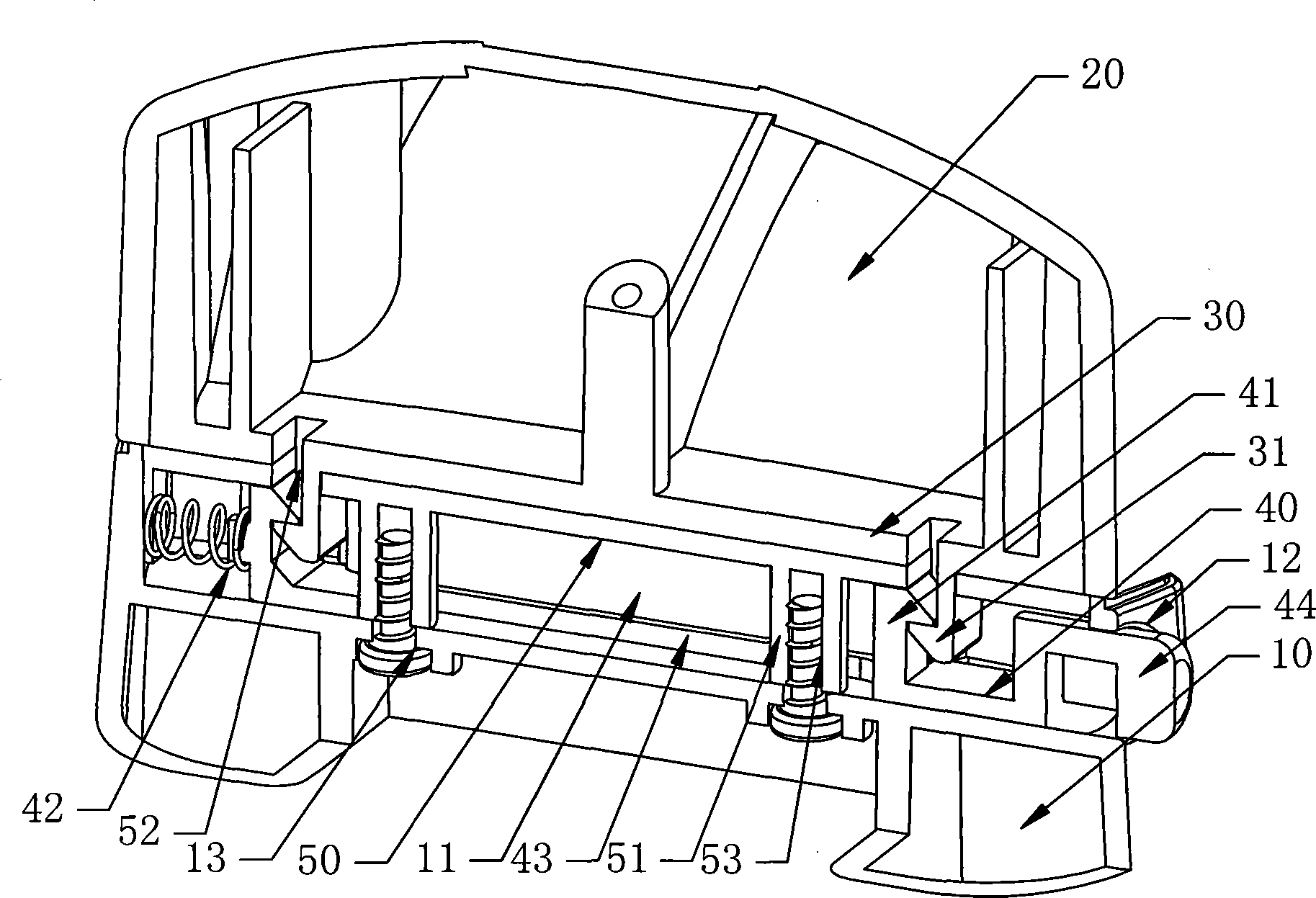

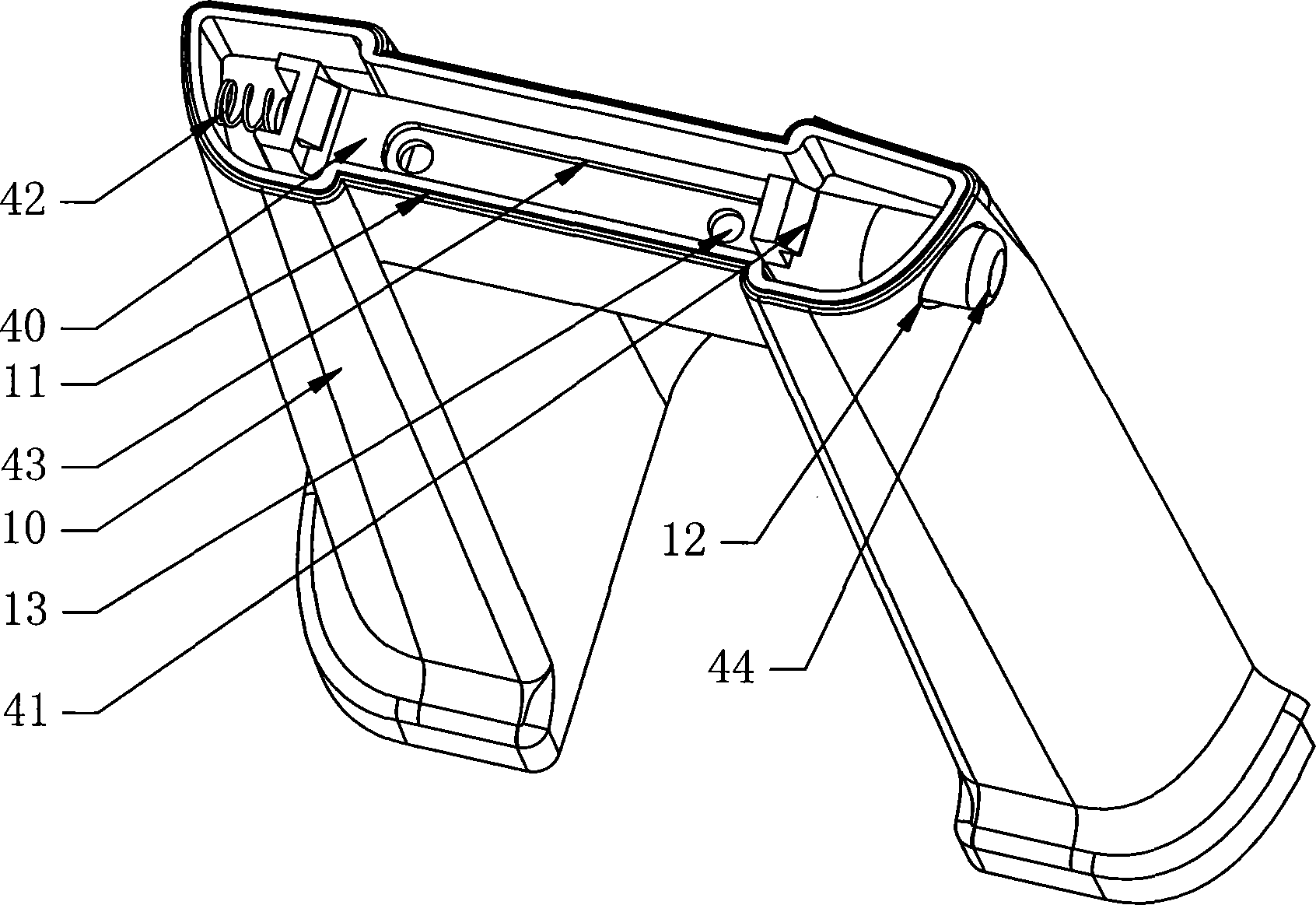

[0024] A noodle mixing machine locking mechanism according to the present invention comprises a base 10 and an upper cover 20 of the main body of the noodle mixing machine, the rear end of the upper cover 20 is hinged to the rear end of the base 10, and the bottom surface of the front end of the upper cover 20 is provided with There is a latch 30, and the latch 30 is used to cooperate with and lock the base 10, so that the upper cover 20 and the base 10 are connected and locked when the noodle mixer is in operation.

[0025] A chute 11 is provided on the top surface of the front end of the base 10, and a shutter 40 that can move laterally is provided in the chute 11, and the latch 30 and the shutter 40 are connected by a buckle, and the bottom side of the chute 11 is A locking spring 42 is provided between the wall and one end of the shutter 40 .

[0026] When the pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap