Micro-mixing detecting chip

A detection chip and micro-mixing technology, which is applied in mixers, color/spectral characteristic measurement, dissolution, etc., can solve the problems of increasing costs, flow dead angles, unfavorable micro-channel flushing and reuse, and increasing the difficulty of micro-channel processing. Achieve the effects of low cost, improved mixing reaction efficiency, and fast and efficient mixed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

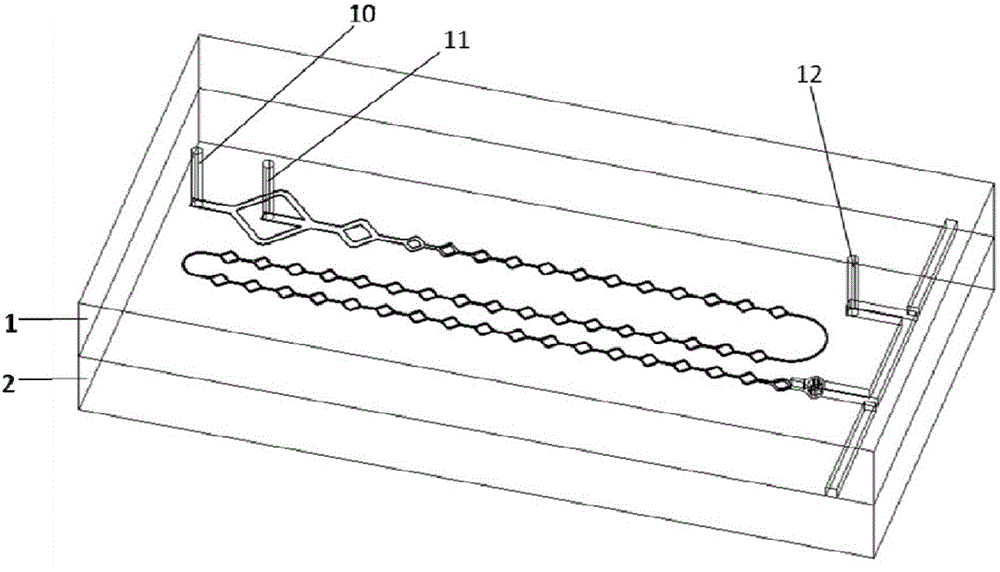

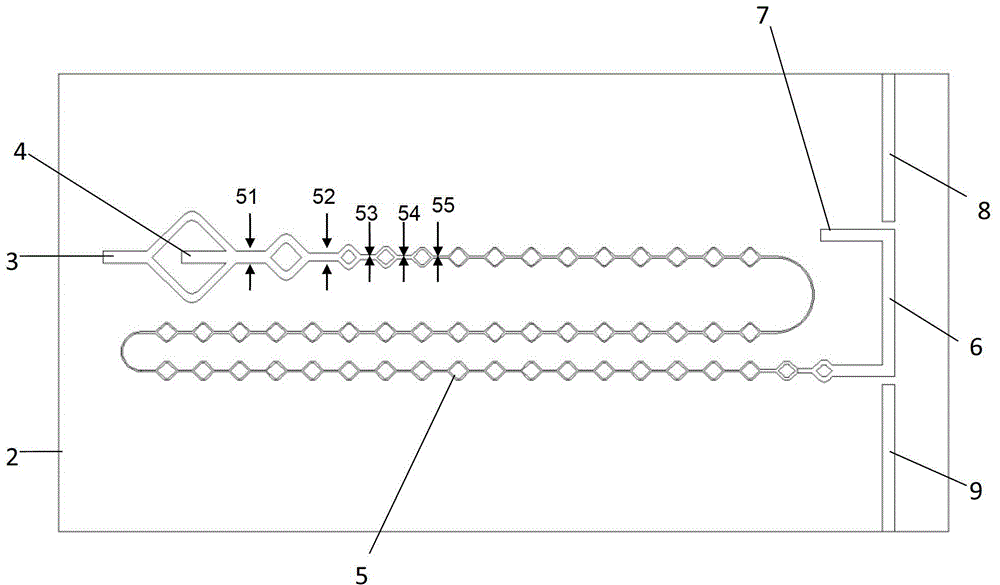

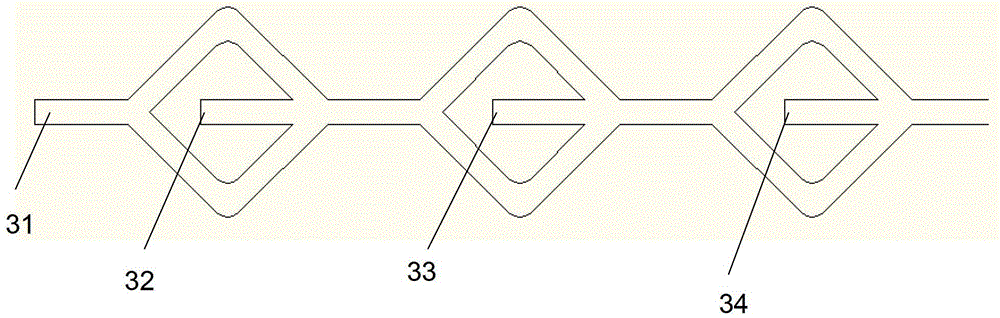

[0018] Such as figure 1 with figure 2 As shown, the embodiment of the micro-mix detection chip of the present invention has two inlets 3, 4 and one outlet 7, and two optical fiber channels 8, 9. This embodiment includes: a cover sheet 1 , a substrate 2 , inlets 3 and 4 , an outlet 7 , a detection channel 6 , optical fiber channels 8 and 9 , and a mixing channel 5 . The first inlet 3 is located at the front end of the second inlet 4, and the two inlets are located on the same straight line and communicate with the mixing channel. The mixing channel at the first inlet 3 is divided into two branches, which merge into the main mixing channel from both sides of the second inlet 4 . The two inlets 3 and 4 communicate with one end of the mixing channel 5, and the liquid A flowing in from the first inlet 3 is divided into two branches after the first inlet 3 flows in, and merges into the trunk of the mixing channel on both sides of the second inlet 4 , mixed with liquid B flowing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com