Automatic oil return device of refrigeration system

A refrigeration system, self-returning technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as insufficient lubrication, compressor oil shortage, compressor operation failure, etc., to achieve easy production operation, simple control, Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

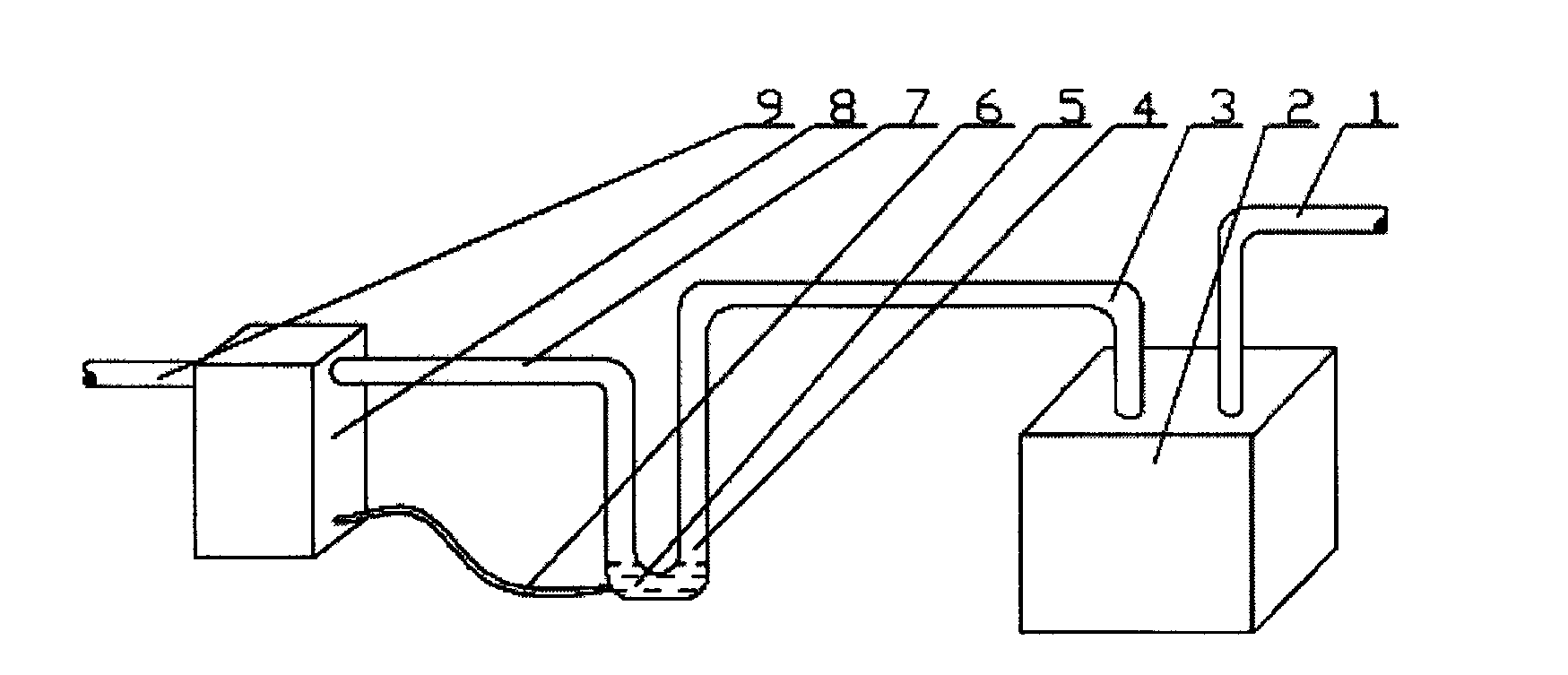

[0013] combine figure 1 The specific embodiment of the present invention is further described:

[0014] According to the technical solution provided by the present invention, a self-oil return device for a refrigeration system includes an exhaust pipe 1, a compressor 2, a suction pipe 3, an oil trap 4, lubricating oil 5, an oil return pipe 6, and an oil collecting bag outlet pipe 7. Oil collecting bag 8, oil collecting bag inlet pipe 9, the compressor 2 is connected in closed loop with the condenser, expansion valve, evaporator, and oil trap 4 in sequence, and the oil collecting bag 8 is installed on the evaporator lowest point.

[0015] The oil return pipe 6 connects the bottom of the oil collecting bag 8 and the bottom of the oil trap 4 , and the bottom of the oil trap 4 is lower than the lowest point of the oil collecting bag 8 .

[0016] Working process of the present invention is:

[0017] In the refrigeration system, the compressor 2 is closed-loop connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com