Electric connection terminal and assembly having the electric connection terminal

An electrical connection and terminal technology, applied in the field of components including the terminal, achieves the effects of reducing the quantity, reducing the price and cost, and having a simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

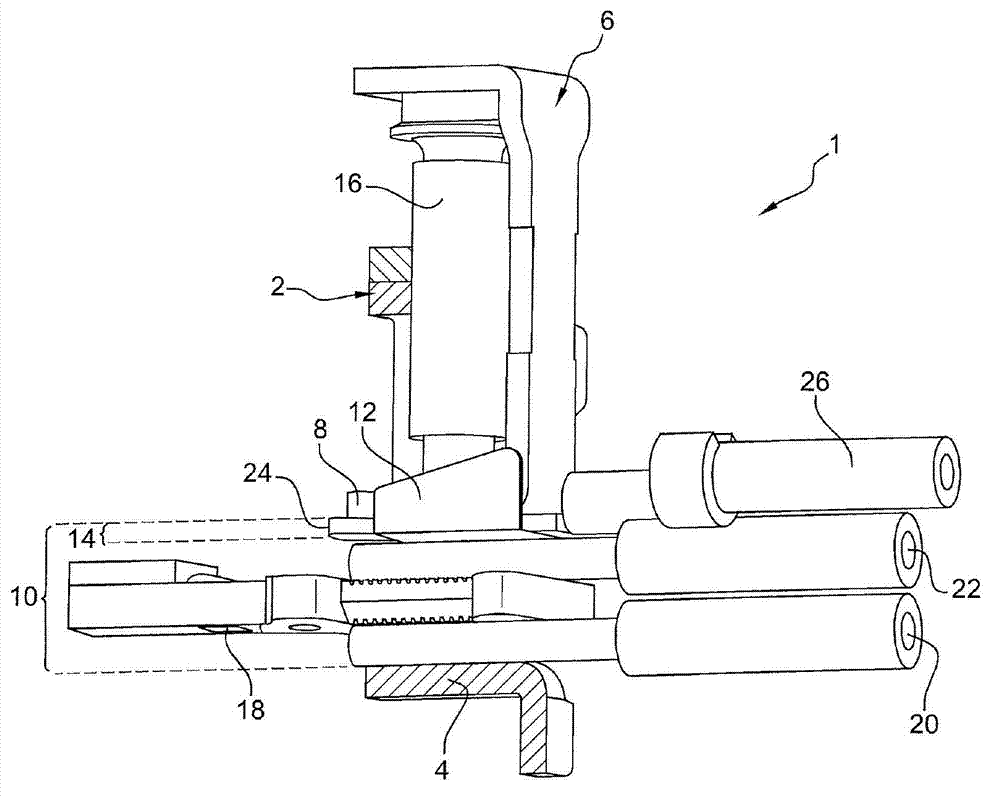

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

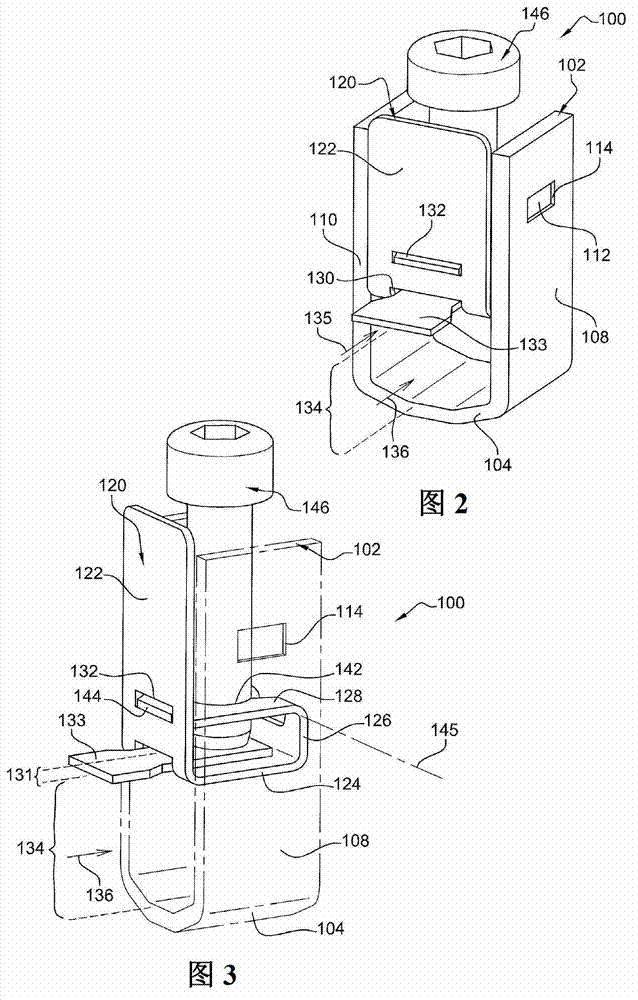

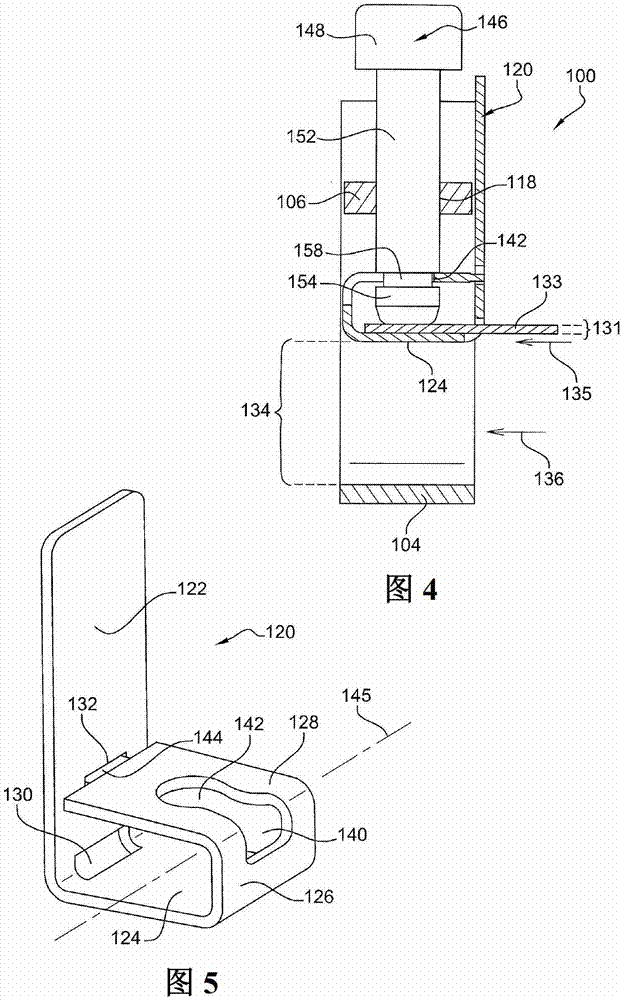

[0062] Figure 2 to 4 The electrical connection terminal 100 according to the present invention is shown. The terminal 100 includes a holder 102, which includes:

[0063] -Anti-support wall 104;

[0064] -The screw wall 106 opposite to the anti-support wall 104 (in Figure 4 Shown in); and

[0065] -Connect the counter-support wall 104 to the connecting walls 108 and 110 of the screwing wall 106.

[0066] The holder 102 is made by plastic deformation of a metal sheet, so the first part of the blade forms the connecting wall 108, the second part forms the counter-support wall 104, and the third part forms the connecting wall 110.

[0067] The screwing wall 106 is added and attached to the connecting walls 108 and 110. For this purpose, the screwing wall 106 includes two protrusions 112, and each of the connecting walls 108 and 110 includes a recess 114 into which a respective protrusion 112 is engaged.

[0068] The screwing wall 106 is provided with a threaded hole 118.

[0069] The term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com