High torque automatic fastening device

A high-torque, automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inaccurate readings of flowmeters, inconsistent flow of flowmeters, wear of bolt thread holes, etc., to ensure accuracy and high efficiency , Protect the normal service life and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

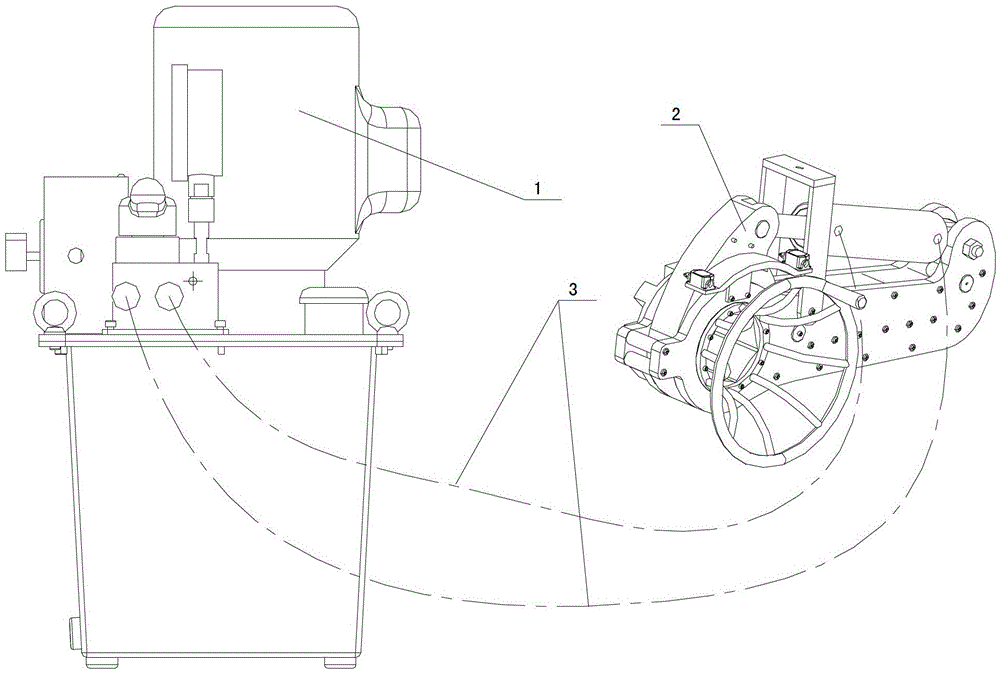

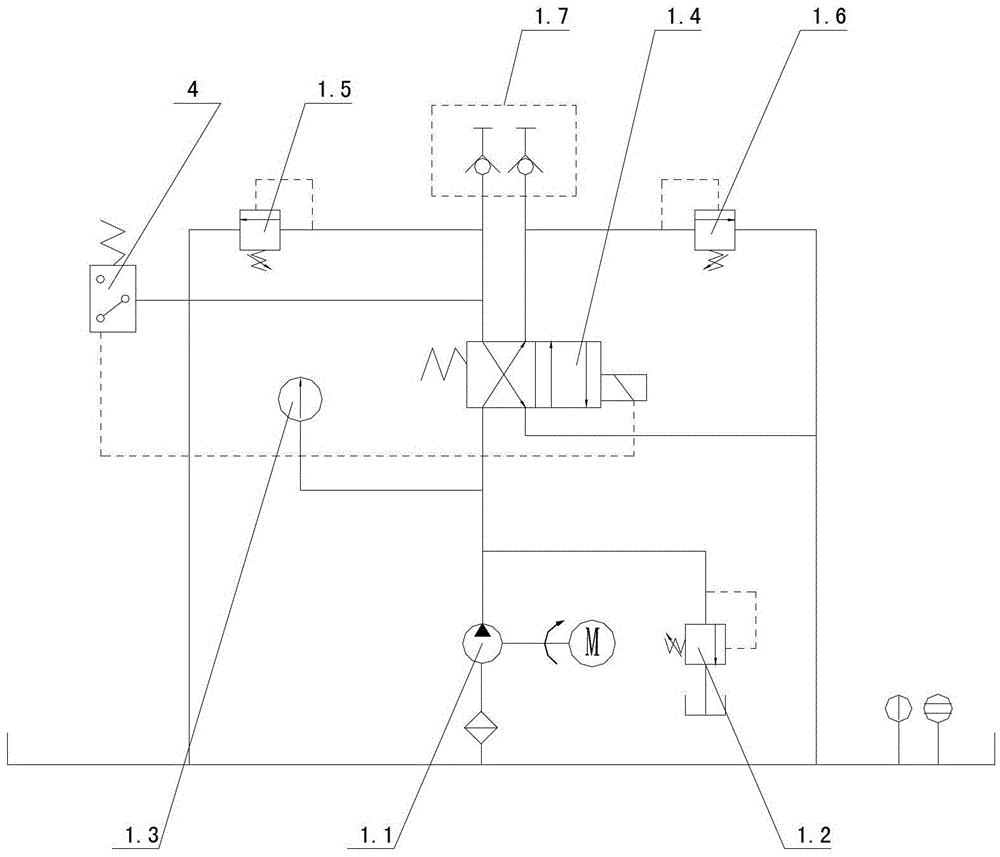

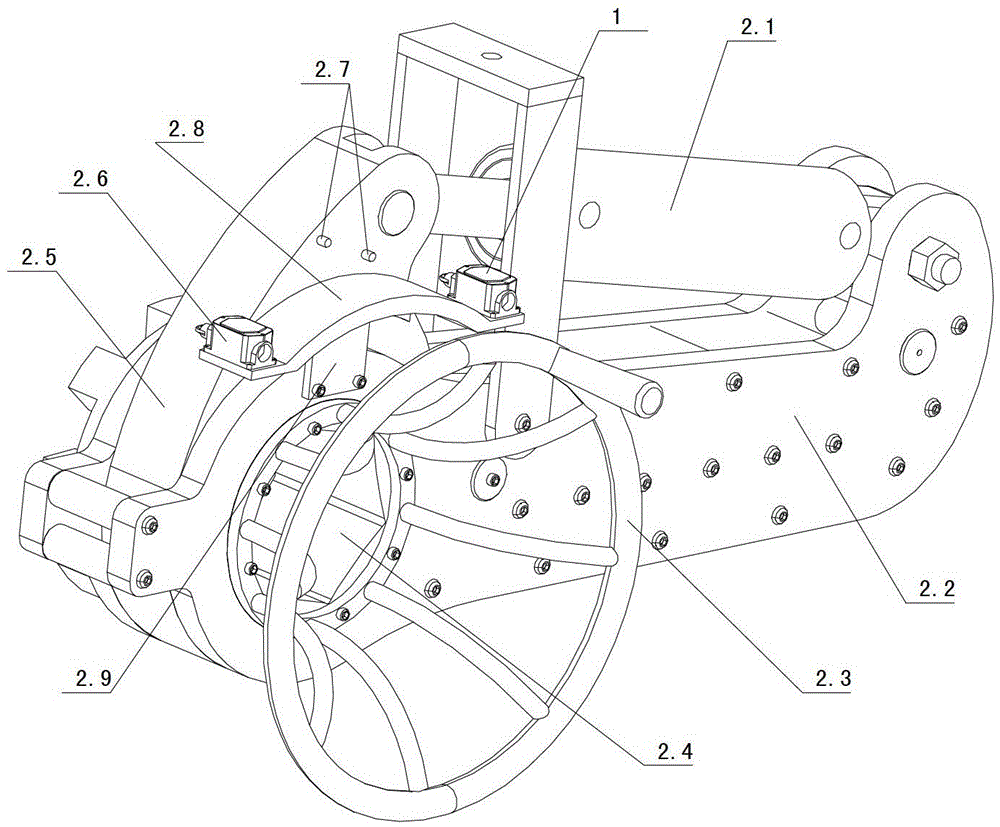

[0020] Depend on Figure 1 to Figure 4 It can be seen from the schematic structural diagram of the large torque automatic fastening device of the present invention that it includes an electro-hydraulic pump station 1 and a hydraulic wrench 2. The electro-hydraulic pump station 1 communicates with the hydraulic wrench 2 through an oil pipe 3. The oil outlet of the pump station 1 is connected with a pressure relay 4, the oil inlet of the pressure relay 4 is connected with the high-pressure output oil circuit of the electromagnetic reversing valve 1.4 in the electrohydraulic pump station 1, and the control port of the pressure relay 4 is connected with the electromagnetic reversing valve. The electromagnet of the valve 1.4 is electrically connected and controlled; the hydraulic wrench 2 is provided with a stroke control device capable of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap