Control method capable of preventing strip steel of galvanizing unit from deflection and belt braking in operation

A control method and strip technology, applied in the directions of transportation and packaging, coiling strips, thin material handling, etc., can solve the problems of unit shutdown, strip broken, scrap and defective products, etc., to prevent strip broken, The effect of reducing strip edge defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

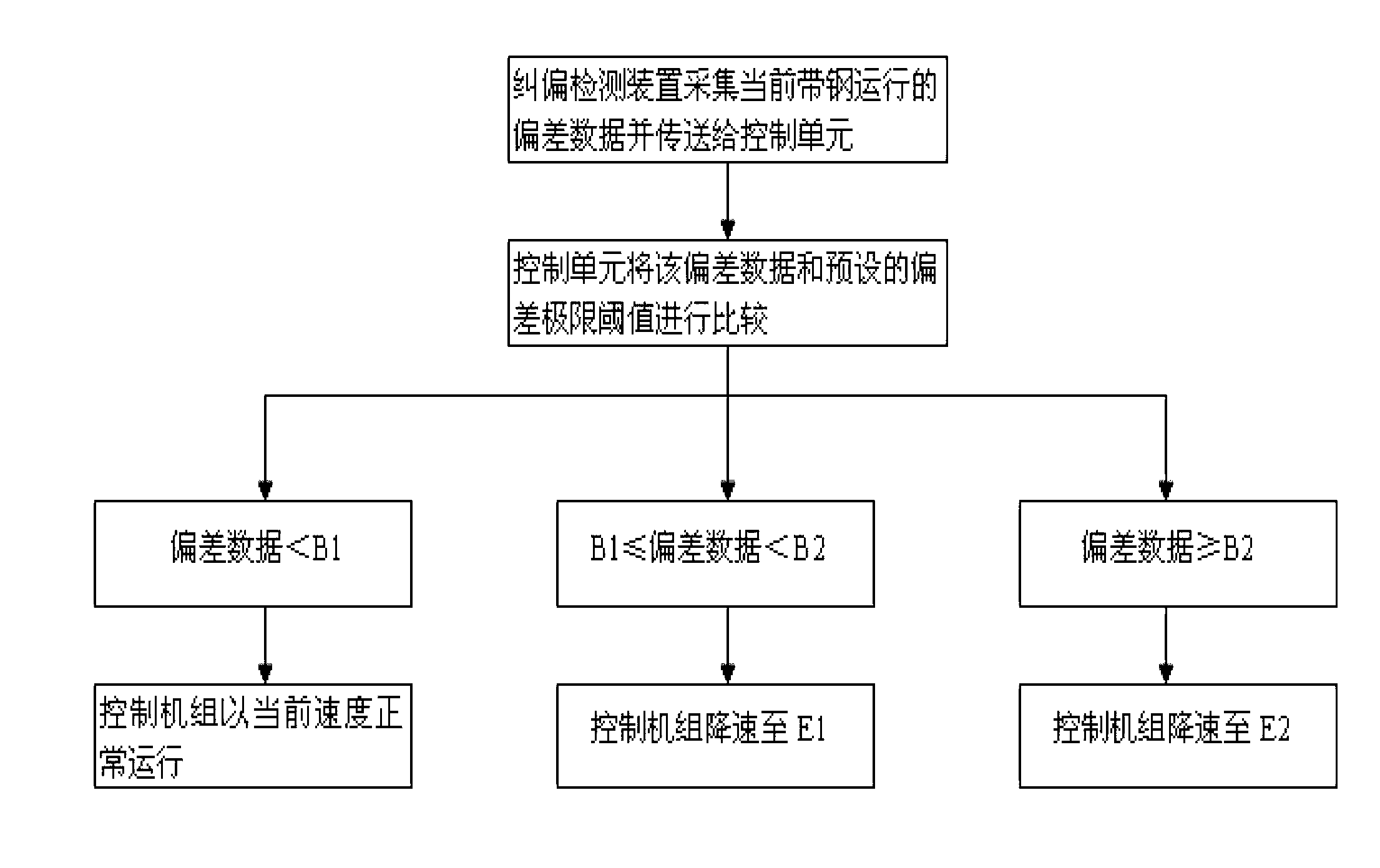

Method used

Image

Examples

Embodiment Construction

[0013] In the galvanizing production process, the annealing furnace section is a very important link. Due to factors such as the material of the strip steel and the temperature in the furnace, when the strip steel runs in the annealing furnace, it often deviates, and the edge of the strip steel is hung in the furnace. Cracks, resulting in broken belts in the furnace. Therefore, in the traditional technology, a deviation correction detection device is specially configured in the annealing furnace section. However, in the original design program of the traditional technology, the unit is not considered to automatically reduce the speed of the unit when the strip is seriously deviated, and the strip is still running at high speed. When the operator finds out, the edge of the steel strip is often cracked or even broken, causing the unit to stop passively, which has a great impact on production and operation, and produces a large amount of waste and defective products. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com