Method of leading Yellow River silt to fill reclamation coal mining subsidence land

A technology for mining subsidence and filling coal mining, applied in soil protection, water resources protection, construction and other directions, can solve the problems of difficult production management, long drainage and consolidation time, high initial investment, and shorten the reclamation time. , Shorten the reclamation period, and the effect of high sand extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

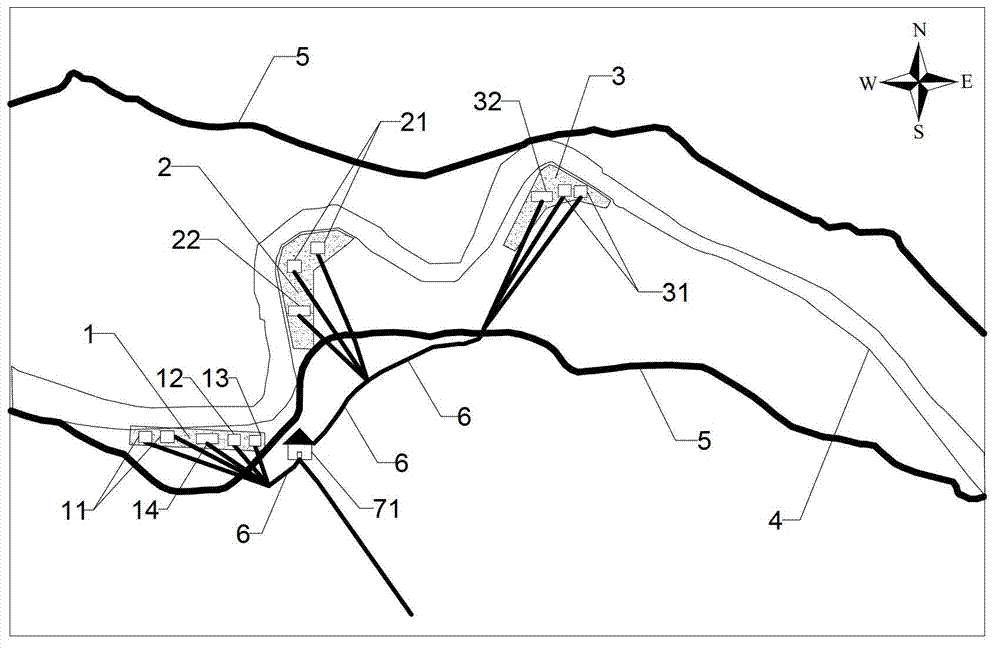

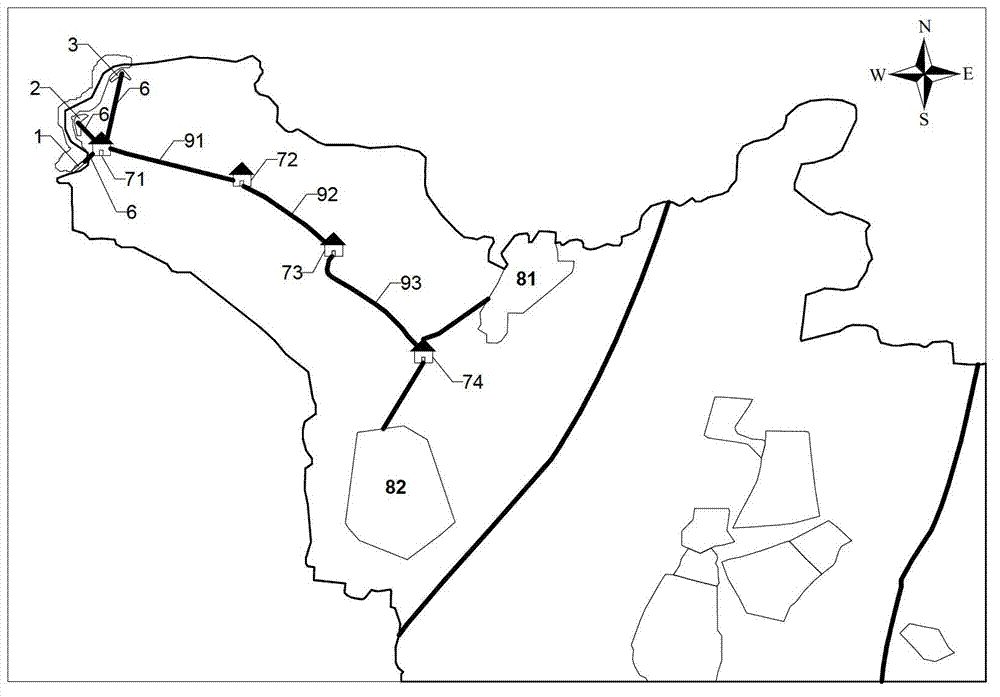

[0020] The method of long-distance diversion of Yellow River silt filling and reclamation coal mining subsidence proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

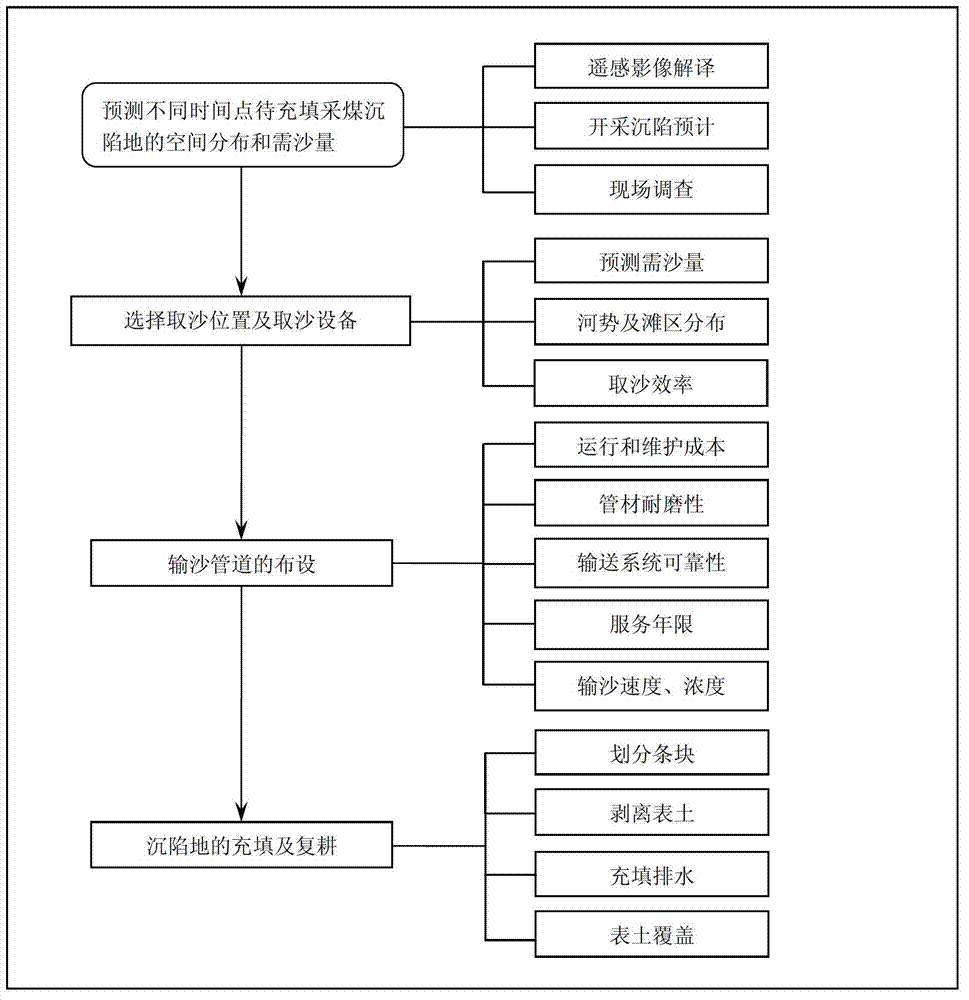

[0021] The method proposed by the present invention for long-distance diversion of Yellow River silt filling to reclaim coal mining subsidence land, such as figure 1 As shown, it is characterized in that the filling of the coal mining subsidence is restored to cultivated land, and the long distance is that the distance of transporting the filling is greater than 30km; it includes the following steps:

[0022] (1) Predict the spatial distribution and sand demand of coal mining subsidence to be filled at different time points: through remote sensing image interpretation, mining subsidence prediction, and on-site investigation methods, the spatial distribution and total subsidence of coal mining subsidence at different time points are dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com