Track-type loose sand transferring device capable of ascending and descending freely and using method of track-type loose sand transferring device

A moving device and track-type technology, which is applied in the field of sand extraction, can solve the problems of unsuitable offshore safety operations and low sand extraction efficiency, and achieve the effects of simple operation, stable operation, and high sand extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

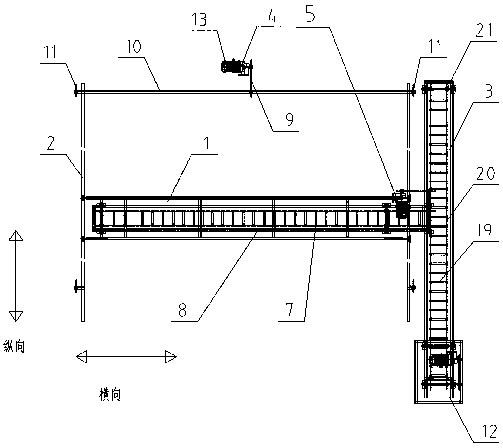

[0022] Embodiment 1, a free-rising rail-type bulk sand transfer device, mainly composed of a horizontal scraper conveying mechanism 1, a track 2, a longitudinal scraper conveying mechanism 3, a longitudinal traction mechanism 4, a hydraulic lifting mechanism 22, and a sand bin 12 Composition: The horizontal scraper conveying mechanism 1 is installed above the track 2, and the transverse scraper conveying mechanism 1 translates on the track 2 through the supporting frame 15. The transverse scraper conveying mechanism 1 includes a horizontal closed rotary circuit, and the horizontal closed rotary circuit The head of the machine is guided upwards to the top of the longitudinal scraper conveying mechanism 3, and the scraper A7 is installed on the horizontal closed rotary circuit; Connected, the longitudinal scraper conveying mechanism 3 includes a longitudinal closed rotary circuit, the head of the longitudinal closed rotary circuit guides upwards to the top of the sand silo 12, an...

Embodiment 2

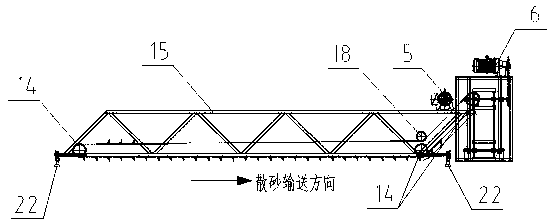

[0023] Embodiment 2, further on the basis of Embodiment 1: the horizontal closed rotary circuit of the horizontal scraper conveying mechanism 1 includes a chain A8, a sprocket A14, the chain A8 and the scraper A7 form a horizontal scraper chain, and the sprocket A14 Form a closed rotary circuit with the horizontal scraper chain; the horizontal scraper conveying mechanism 1 also includes a motor A5 and a support frame 15, the entire horizontal closed rotary circuit is installed and fixed in the support frame 15, and the motor A5 is installed above the support frame 15, The motor A5 drives the sprocket A14 to rotate.

Embodiment 3

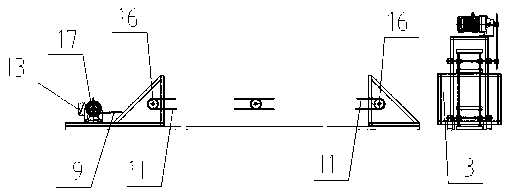

[0024] Embodiment 3, further on the basis of Embodiment 2: the longitudinal closed rotary circuit of the longitudinal scraper conveying mechanism 3 includes a chain B20, a sprocket E21 and a motor B6, and the chain B20 and the scraper B19 form a longitudinal scraper chain, The sprocket E21 and the longitudinal scraper chain form a closed rotation loop, and the sprocket E21 is connected with the motor B6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com