Prediction Method of Drum Strength of Sintered Ore

A technology of drum strength and prediction method, applied in the field of prediction, can solve the problems of poor generalization of topology structure and inability to take into account the prediction accuracy and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

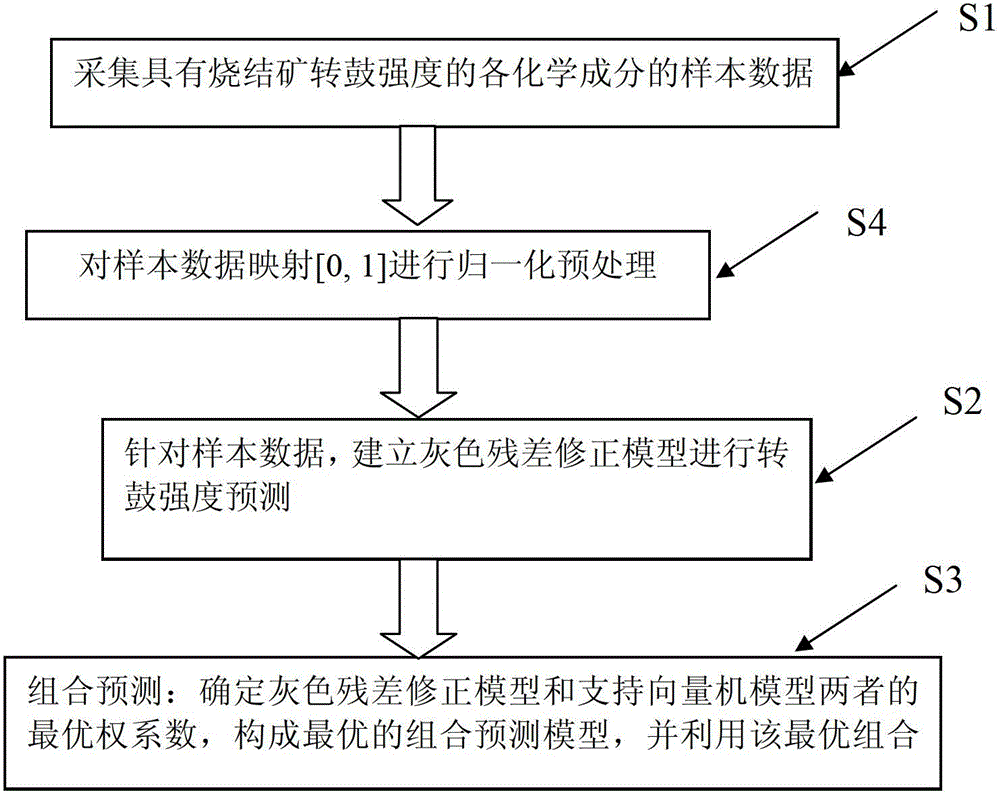

[0053] refer to figure 1 , the present invention is a method for predicting the strength of a sinter drum, comprising two steps of establishing a prediction model and using the established prediction model to predict the strength of the drum, and the method for establishing a prediction model includes

[0054] S1. Collect sample data of various chemical components with sinter drum strength;

[0055] S2. Based on the sample data, a gray residual correction model is established to predict the strength of the drum;

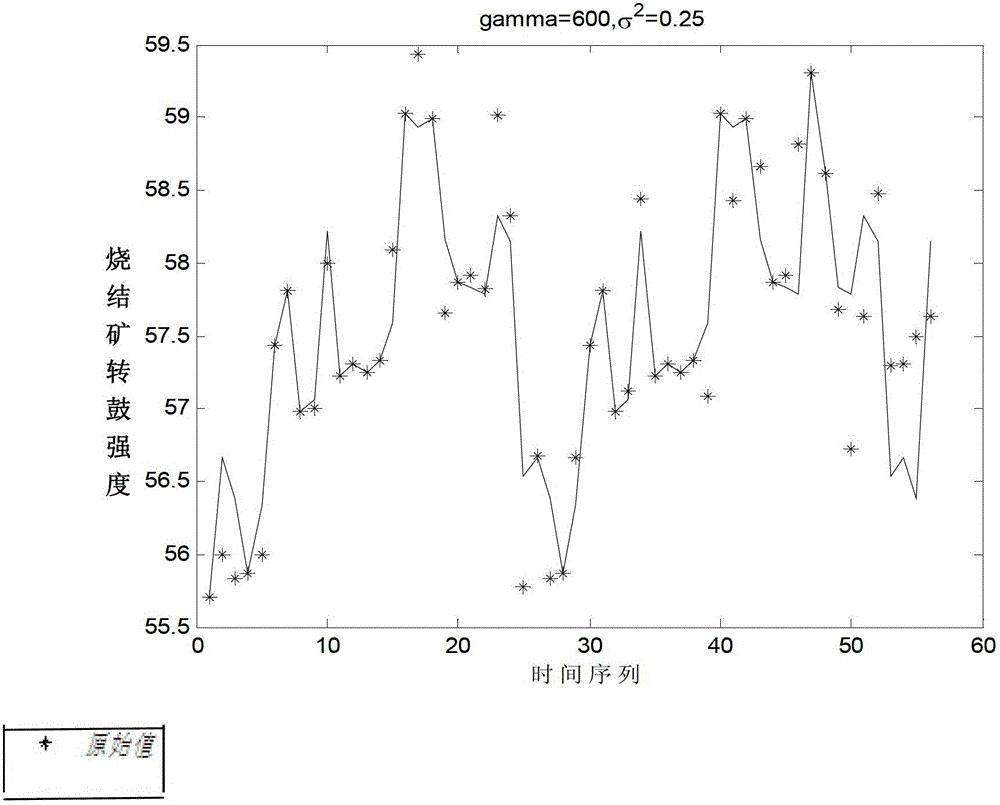

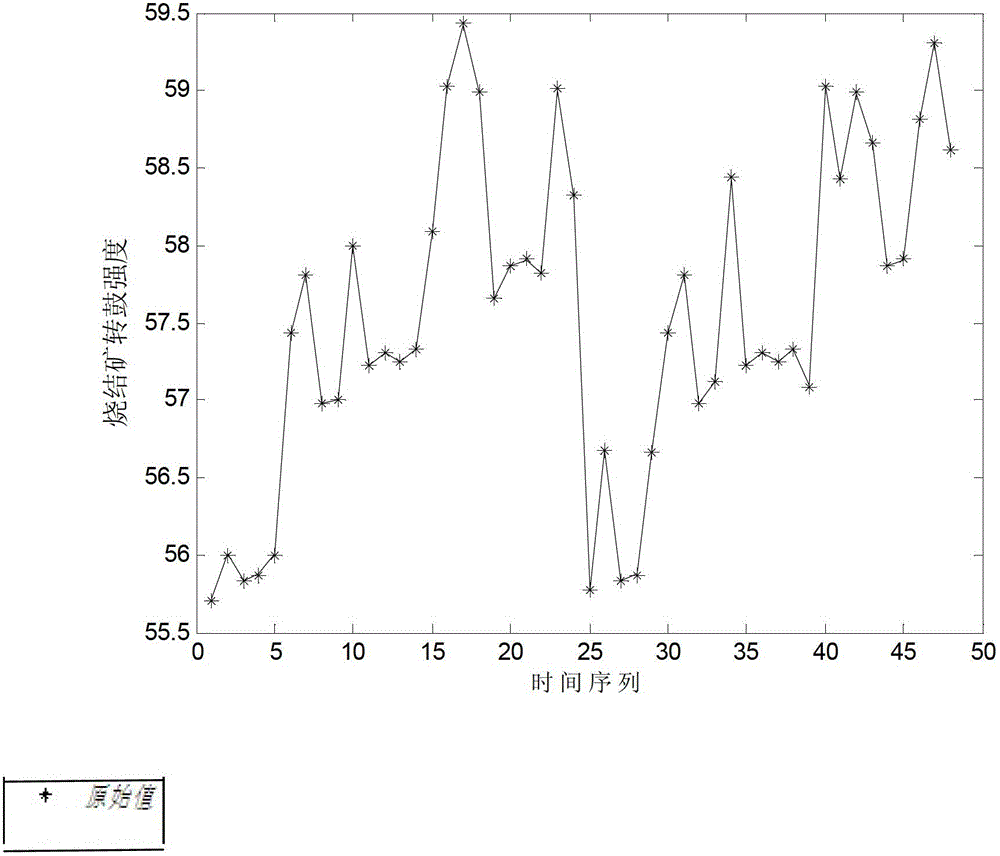

[0056] The gray residual correction model (Grey Model), referred to as GM model, is the basic model of gray system theory and the foundation and core of gray theory. It is based on the gray module (the so-called module refers to the continuous curve of the time series X(0) on the time data plane or the area enclosed by the approximate curve and the time axis), and is abbreviated by the differential fitting method. In the gray residual correction model, the part bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com