Preparation method of antibacterial polypiperazine-amide nanofiltration membrane

An antibacterial, polypiperazine technology is applied in the field of preparation of antibacterial polypiperazine amide nanofiltration membranes, which can solve problems such as fouling membranes, achieve easy operation, simple preparation method, improve pollution resistance and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Configure a mass concentration of 0.2% trimesoyl chloride (TMC) and a mass concentration of 0.005% 2,4,6-trichlorophenoxycarbonyl chloride mixed uniform IsoparG oil solution; the polysulfone base film is immersed in a mass concentration of 0.1 % piperazine aqueous solution (containing sodium dodecylsulfonate with a mass concentration of 0.008%) for 80s, take it out and dry it in the air, wherein; after the solution is dried, contact with the mixed organic phase solution for 40s; The sheet was placed in a vacuum oven at 90° C. for 10 minutes and then taken out.

[0016] Use 2000ppm of sodium sulfate aqueous solution and sodium chloride aqueous solution to test the initial performance of the membrane under 1MPa pressure. 2 SO 4 The desalination rates of NaCl and NaCl are 98.7% and 51.9%, respectively, and the flux is 58.56L / m 2 .h.

Embodiment 2

[0018] Membrane antibacterial performance test: According to the guiding principles of the second part of the "Chinese Pharmacopoeia" 2010 edition microbial limit, a certain CFU of bacterial liquid is fixed on the membrane sample to be tested by the method of filtration, and then pasted on a suitable medium. After 24 hours of cultivation, the membrane was removed, printed and dyed to a disposable sterile filter membrane, and the filter membrane was transferred to a culture plate for 48 hours according to the method of microbial limit determination, and the antibacterial activity of the membrane was investigated by microbial counting.

[0019] Test results: The contact inhibition rate of the membrane against Aspergillus niger was 52.1%, and the contact inhibition rate against Escherichia coli was 53.7%.

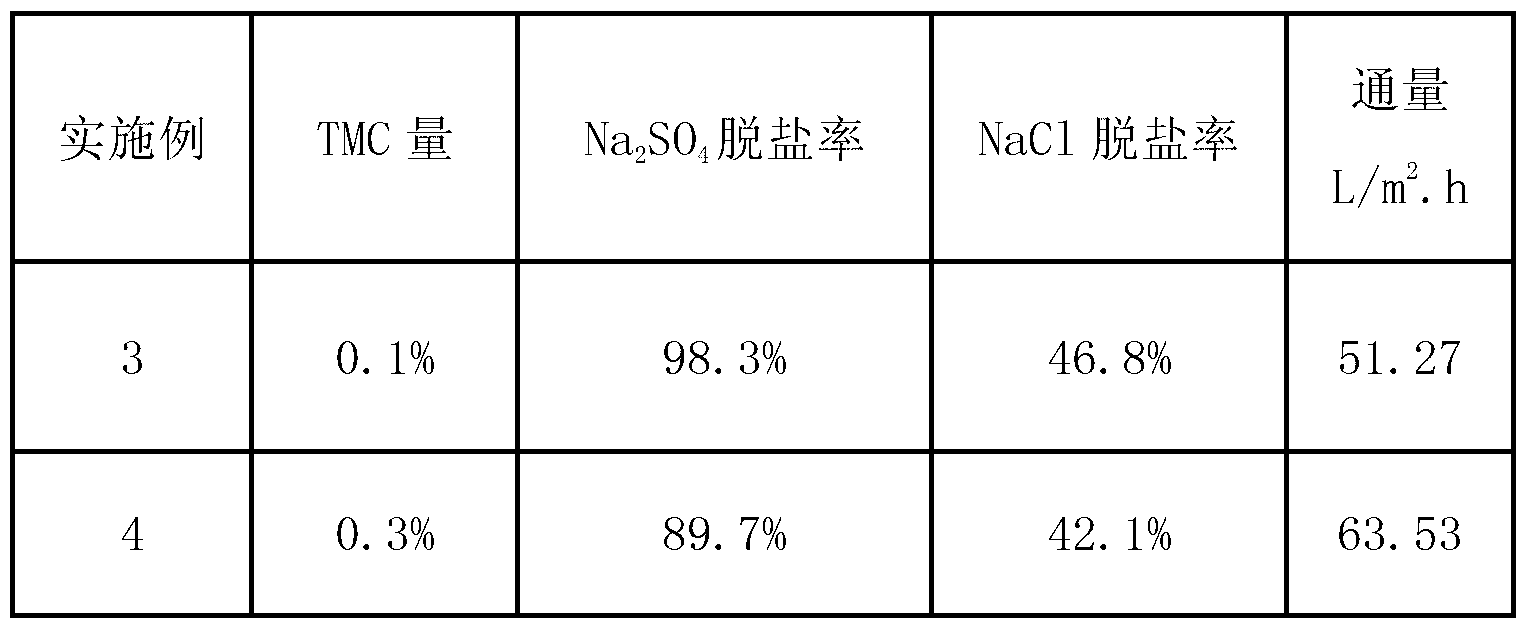

Embodiment 3-4

[0021] Change the amount of trimesoyl chloride added in the oil phase, and the other steps are the same as in Example 1 to prepare a composite film and test it. The results are as follows:

[0022]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap