A kind of antibacterial filter paper and preparation method thereof

A filter paper and pretreatment technology, applied in filter paper, separation methods, chemical instruments and methods, etc., can solve the problems of no antibacterial effect and poor antibacterial effect, and achieve the effect of significant promotion value and stable antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

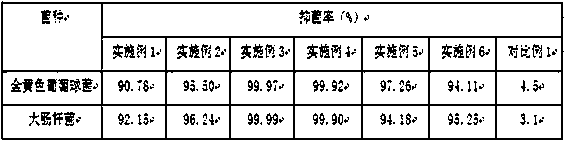

Examples

Embodiment 1

[0023] A preparation method of antibacterial filter paper, comprising the following steps:

[0024] (1) Filter paper pretreatment: add the filter paper to the aqueous solution of silane coupling agent KH-550, the mass-to-volume ratio (g / mL) of the filter paper and the silane coupling agent is 1:6, stir at low speed for 1 hour, take it out to dry, and then Put it in a vacuum drying box, first dry it at 50 °C for 2 hours, and then dry it at 80 °C for 1 hour to obtain a pretreated filter paper; the filter paper is glass fiber filter paper, and the glass fiber content accounts for more than 50% of the total mass of the filter paper. ;

[0025] (2) Styrene grafting: adding the pretreated filter paper in step (1) into the solvent 1,2-dichlorobenzene, stirring evenly, then adding the catalyst and styrene, and stirring for 2 hours to carry out the grafting reaction; the catalyst is CuBr / bipyridine, and the mass / volume / volume ratio (g / mL / mL) of filter paper, 1,2-dichlorobenzene and st...

Embodiment 2

[0028] A preparation method of antibacterial filter paper, comprising the following steps:

[0029] (1) Pretreatment of filter paper: Add the filter paper to the aqueous solution of silane coupling agent KH-550, the mass-volume ratio (g / mL) of filter paper and silane coupling agent is 1:7, stir at low speed for 1.5h, take it out to dry, Then it was placed in a vacuum drying box, first dried at 50 °C for 2.5 hours, and then dried at 80 °C for 2 hours to obtain pretreated filter paper; the filter paper was glass fiber filter paper, and the glass fiber content accounted for 50% of the total mass of the filter paper. %above;

[0030](2) Styrene grafting: adding the pretreated filter paper in step (1) into the solvent 1,2-dichlorobenzene, stirring evenly, then adding catalyst and styrene, and stirring for 2.5 hours to carry out the grafting reaction; The catalyst is CuBr / bipyridine, and the mass / volume / volume ratio (g / mL / mL) of filter paper, 1,2-dichlorobenzene and styrene (g / mL / m...

Embodiment 3

[0033] A preparation method of antibacterial filter paper, comprising the following steps:

[0034] (1) Pretreatment of filter paper: Add the filter paper to the aqueous solution of silane coupling agent KH-550, the mass-volume ratio (g / mL) of filter paper and silane coupling agent is 1:8, stir at low speed for 2 hours, take it out to dry, and then It is placed in a vacuum drying box, first dried at 55 °C for 2.5 hours, and then dried at 85 °C for 1 hour to obtain pretreated filter paper; the filter paper is glass fiber filter paper, and the glass fiber content accounts for 50% of the total mass of the filter paper. above;

[0035] (2) Styrene grafting: adding the pretreated filter paper in step (1) into the solvent 1,2-dichlorobenzene, stirring evenly, then adding catalyst and styrene, and stirring for 3 hours to carry out the grafting reaction; the catalyst is CuBr / bipyridine, and the mass / volume / volume ratio (g / mL / mL) of filter paper, 1,2-dichlorobenzene and styrene is 1:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com