Material classification device

A material classification and equipment technology, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

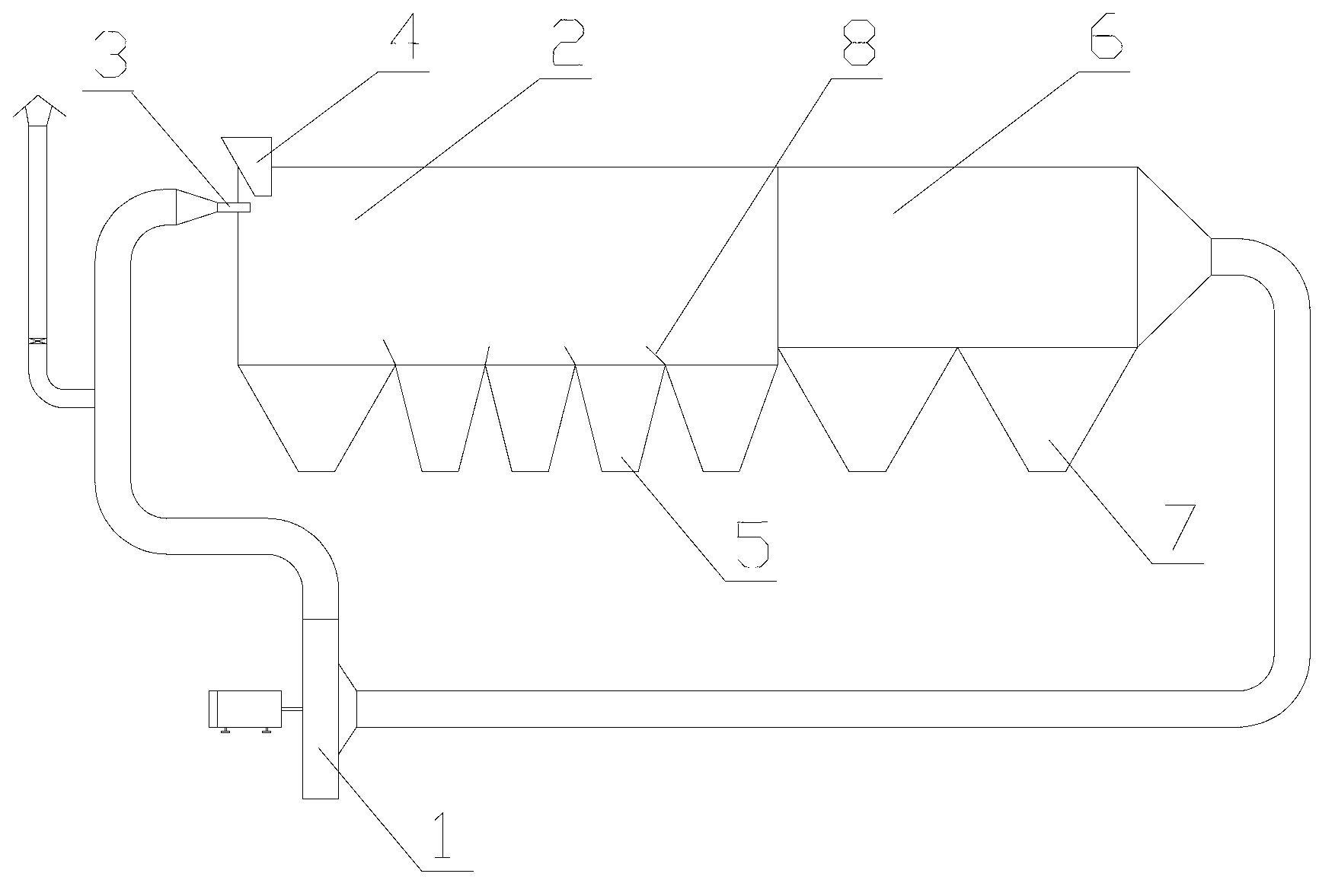

[0033] see figure 1 , one A kind of material classifying equipment, comprises blower fan 1, particle fraction drop chamber 2 and the air flow nozzle 3 and feed inlet 4 that are arranged on described particle fraction drop chamber 2 sidewalls, and described air flow nozzle 3 and described blower fan 1 connection, the straight line where the air flow nozzle 3 is located has an intersection with the straight line where the feed inlet 4 is located, and the straight line where the outlet of the air flow nozzle 3 is a horizontal line;

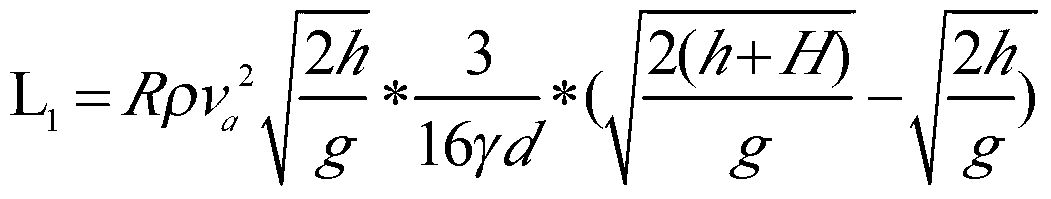

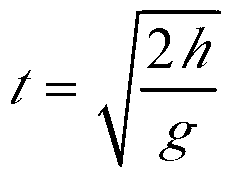

[0034] Several hoppers 5 are arranged at the bottom of the particle fraction falling chamber 2, and the hopper 5 closest to the feed inlet 4 is used as the first hopper, and the width of the first hopper is W 1 :

[0035] W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com