A cable rack

A pay-off frame and cable technology, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of hidden dangers in production safety, high labor intensity of construction personnel, and complicated conditions of electric power construction sites, etc., and achieve reduction The effect of labor intensity, avoiding scattering and intertwining, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

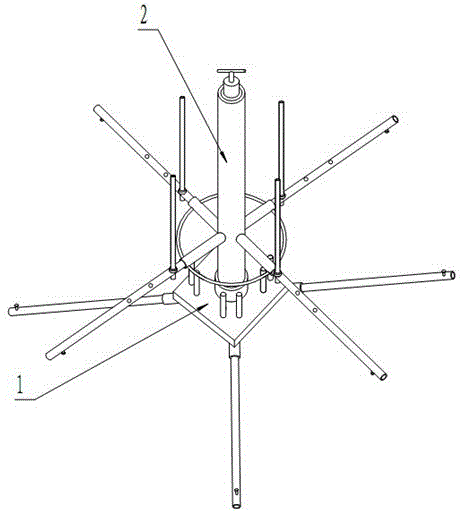

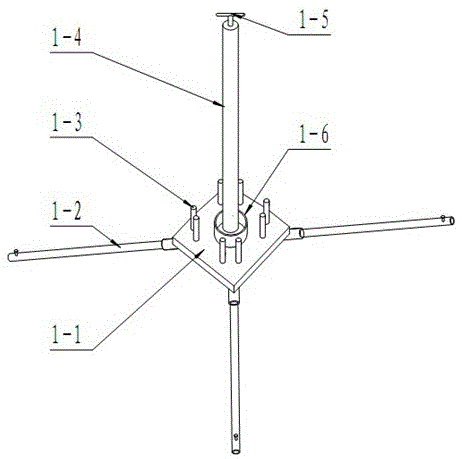

[0022] see figure 1 , the present invention includes a rotating part 2 and a fixed part 1.

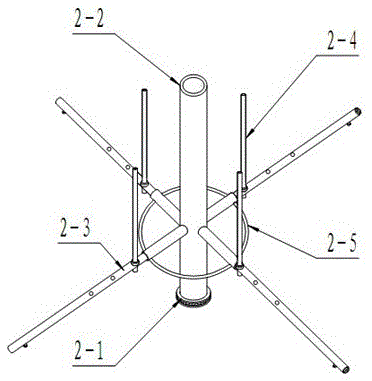

[0023] see image 3 , Figure 4 , Figure 5 , the rotating part 2 of the present invention is composed of a sleeve 2-2, a pressure bearing 2-1, a support seat 2-5, a support arm 2-3 and a limit arm 2-4, and the bottom of the sleeve 2-2 is installed with a pressure Bearing 2-1, the pressure bearing 2-1 is set on the outside of the sleeve 2-2, and it is assembled with the outer wall of the sleeve 2-2 in an interference fit manner, and the support seat 2-5 is fixed on the sleeve 2-2 On the outer wall, a group of support arms 2-3 are evenly distributed along the circumferential direction of the support base 2-5. The support arms 2-3 are detachable structures, and the number thereof is not less than four. Each support arm 2-3 3 are provided with a set of limit arm assembly holes 2-3-1, the number of the limit arm assembly holes 2-3-1 is not less than three, and welding is provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com