Reactive cationic polyacrylate emulsion and preparation method and application thereof

A technology of polyacrylate emulsion and butyl acrylate, which is applied in the direction of adding water repellent and reinforcing agent to improve water resistance, paper strength, water resistance and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] The steps of the preparation method of following embodiment are as follows:

[0034] 1. Preparation of cationic polyacrylate emulsion

[0035] In a constant temperature water bath at a temperature of 50-70°C, add protective colloid polyvinyl alcohol (PVA), cationic emulsifier cetyltrimethylammonium chloride (1631), nonionic emulsifier alkylphenol polyoxyethylene Ether-10 (OP-10), reactive emulsifier allyloxy nonylphenol polyoxyethylene (ANPEO-10), functional monomer acrylamide (AM), cationic monomer diallyl dimethyl chloride Ammonium (DMDAAC), hard segment monomer styrene (St) and soft segment monomer butyl acrylate (BA) are pre-emulsified in the reactor, the pre-emulsification stirring time is 0.5-1.0h, and the stirrer speed is 400- 1000r / min to obtain a pre-emulsified mixture.

[0036] Four-fifths of the above pre-emulsified mixture was withdrawn and the remaining one-fifth was left in the reactor. Set the temperature of the water bath at 80-85°C. After the tempera...

Example Embodiment

[0051] Example 1

[0052] Reactive cationic polyacrylates are prepared through the following steps:

[0053] 1. Synthesis and properties of cationic polyacrylate emulsion

[0054] The polymerization formula of the cationic polyacrylate emulsion is: the amount of the mixture of styrene (St) / butyl acrylate (BA) with a mass ratio of 1:1 is 88% of the total monomer amount, and the amount of acrylamide (AM) is the total The amount of monomer is 7%, the amount of diallyl dimethyl ammonium chloride (DMDAAC) is 5% of the total monomer amount, the amount of protective colloid polyvinyl alcohol is 0.3% of the total monomer amount, cationic emulsification The amount of cetyltrimethylammonium chloride (1631) is 2% of the total monomer amount, and the amount of nonionic emulsifier alkylphenol polyoxyethylene ether-10 (OP-10) is 3% of the total monomer amount. %, the reactive emulsifier allyloxy nonylphenol polyoxyethylene (ANPEO) is 7% of the total monomer amount, and the initiator potas...

Example Embodiment

[0070] Example 2

[0071] The preparation and properties of the reactive cationic polyacrylate emulsion in Example 2 are the same as those in Example 1.

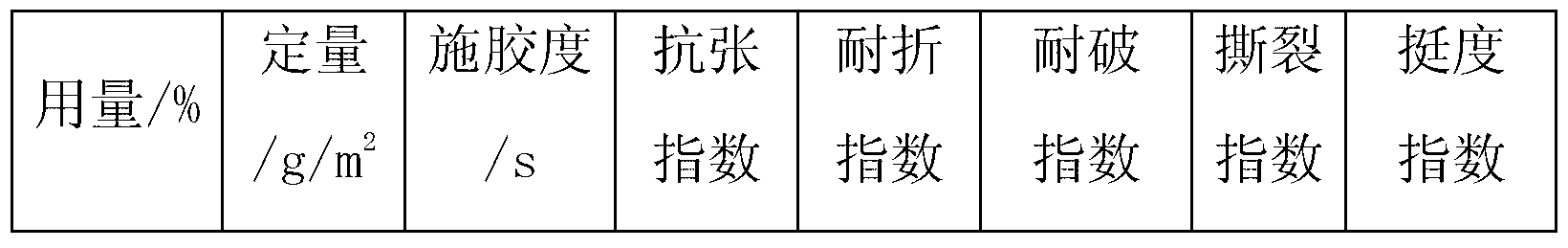

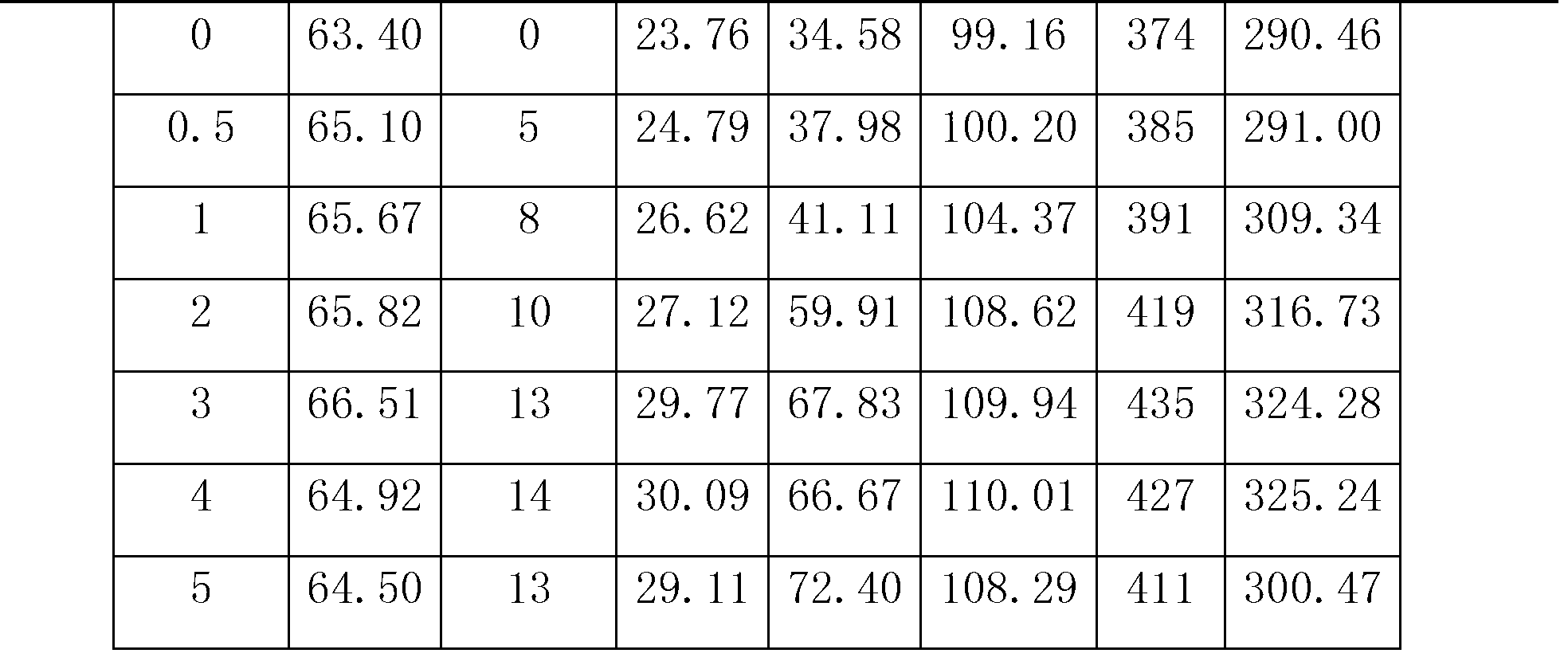

[0072] The reactive cationic polyacrylate emulsion is used in paper coating, and the specific implementation method is: the paper is fixed on the Endupap multifunctional coating machine table. Set the drying temperature to 80°C, the drying time to 2min, the coating speed to 2m / min, and use the automatic mode for doctor blade coating. Put down the scraper, use a disposable straw to absorb an appropriate amount of reactive cationic polyacrylic acid emulsion, apply it evenly under the scraper, ensure that the amount can cover the entire paper, and press the start button to start coating. Each sample was coated with at least 10 sheets, and the performance of the coated paper was measured. The strength performance test results of the coated paper are listed in Table 2, and the printing performance of the coated paper is listed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap