Foam magnesium oxychloride cementitious composite material for prefabricated partition wallboards and preparation method of foam magnesium oxychloride cementitious composite material

A composite material and a technology of magnesium oxychloride, which are applied in the field of foamed magnesium oxychloride cementitious composite materials and their preparation, can solve the problems of warping deformation, poor water resistance, large volume and the like, and achieve the improvement of toughness, reduction of production cost and strength. And the effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

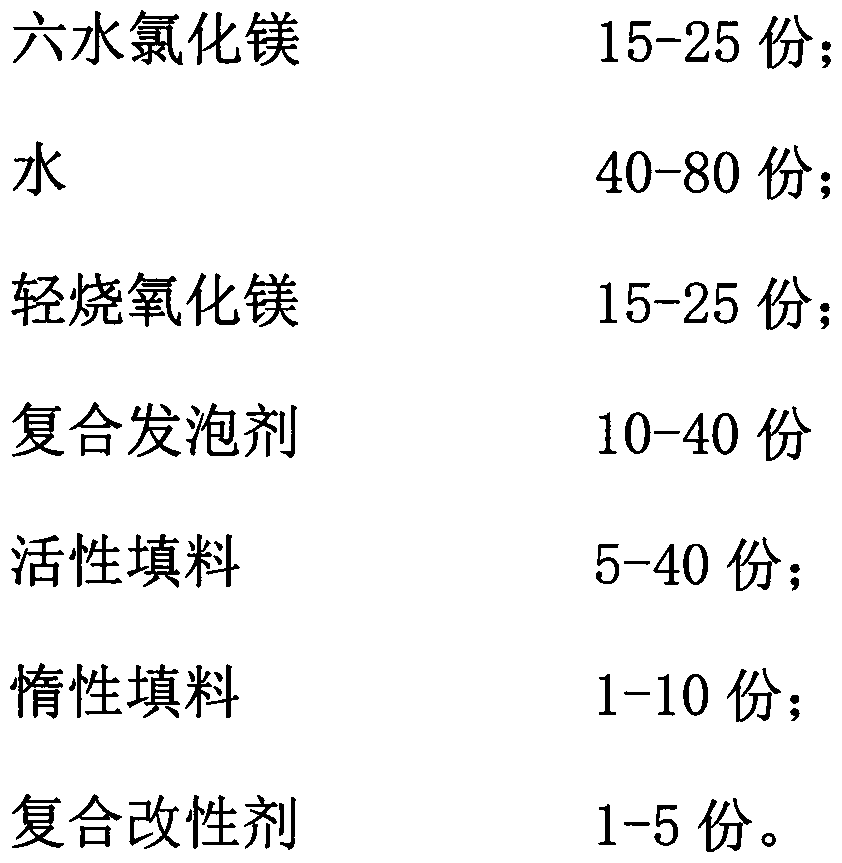

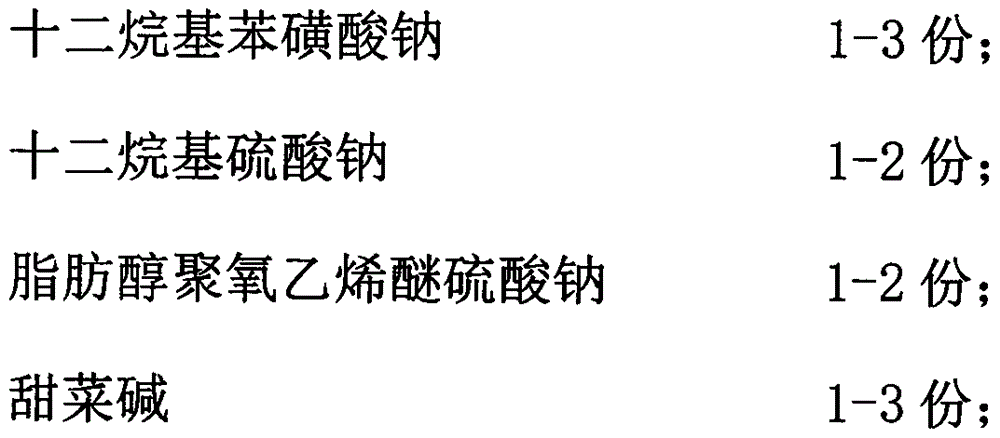

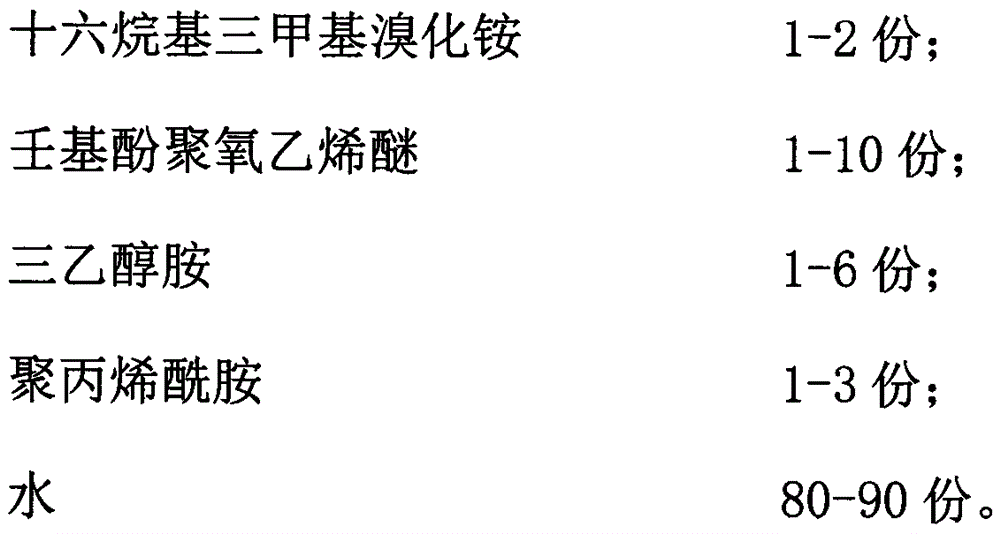

Method used

Image

Examples

Embodiment 1

[0023] A foamed magnesium oxychloride cementitious composite material for prefabricated partition walls, comprising 16 parts of magnesium chloride hexahydrate, 56 parts of water, 80 parts of light-burned magnesium oxide, 20 parts of composite foaming agent, 25 parts of active fillers, inert 2 parts of filler and 2 parts of compound modifier.

[0024] Preparation of a foamed magnesium oxychloride cementitious composite material for prefabricated partition wall panels:

[0025] A. Mix 16 parts of magnesium chloride hexahydrate and 56 parts of water into an aqueous solution of magnesium chloride with a specific gravity of 1.23, mix with 80 parts of light-burned magnesium oxide and 25 parts of active fillers, stir for 5 minutes and then add 2 parts of composite modifier and inert filler 2 in sequence After stirring for 15 minutes, the foam prefabricated by 25 parts of composite foaming agent was added, and after stirring for 5 minutes, the foamed magnesium oxychloride cemented composit...

Embodiment 2

[0031] A magnesium oxychloride cementitious composite material for prefabricated partition wall panels, comprising 20 parts of magnesium chloride hexahydrate, 57 parts of water, 100 parts of light burnt magnesium oxide, 30 parts of composite foaming agent, 20 parts of active filler, and 3 parts of inert filler Parts and 3 parts of compound modifier.

[0032] Preparation of a foamed magnesium oxychloride cementitious composite material for prefabricated partition wall panels:

[0033] A. Mix 20 parts of magnesium chloride hexahydrate and 57 parts of water into an aqueous solution of magnesium chloride with a specific gravity of 1.24, add 100 parts of light-burned magnesium oxide and 20 parts of active fillers to mix, stir for 5 minutes and then add 3 parts of composite modifier and 3 parts of inert fillers in sequence After stirring for 20 minutes, add 30 parts of foam prefabricated by composite foaming agent, and stir for 3 minutes to obtain the foamed magnesium oxychloride cementi...

Embodiment 3

[0039] According to the formula and preparation method described in Example 2, the addition amount of the composite foaming agent was changed to prepare a series of foamed magnesium oxychloride cementitious composite materials, and the effect of the addition amount of the composite foaming agent on the performance of the cementitious composite material was investigated.

[0040] Table 3 The effect of different compound modifiers

[0041]

[0042] According to the formula and preparation process described in Example 2, the addition amount of the composite foaming agent was changed, and the resulting foamed magnesium oxychloride cementitious composite material had a smooth and even surface, no warpage, deformation, frost cracking, etc., and all had relatively high mechanical strength. High and low bulk density, it can be seen that the foamed magnesium oxychloride cementitious composite materials prepared with different compound foaming agent addition amounts can meet the requirements ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com