Special water spray fire resisting shutter device for tunnel

A fire shutter, water spray technology, applied in mining devices, safety devices, fire prevention and other directions, can solve the problems of fire shutters not suitable for tunnels, fire-resistant limit temperature is not high, increasing shutter manufacturing costs, etc., to prevent The effect of fire spread, lower fire resistance limit temperature and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing:

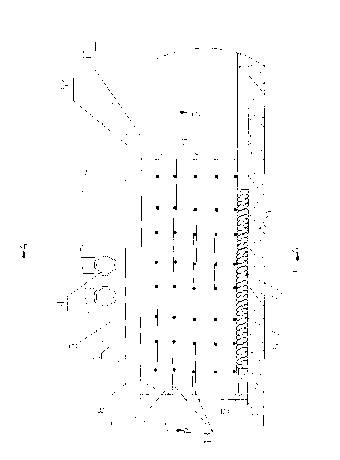

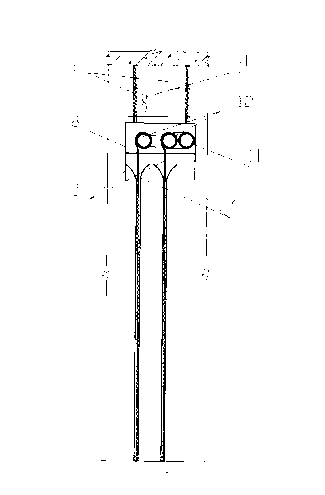

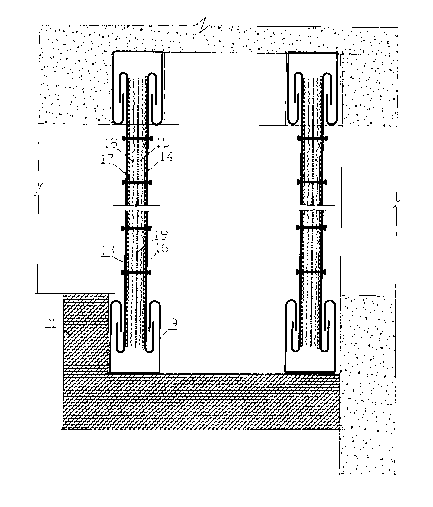

[0015] Special water spray fire-proof roller shutter device for tunnels, including fixed curtain 3, movable roller shutter 2, roller shutter box 8, roller shutter motorized box 22, reversible smoke exhaust fan 4, fire water supply main pipe 27, water distribution branch pipe 24 and water spray nozzle 23. The fire-proof roller shutter is set at the connection between the tunnel parking belt 10 and the tunnel driving belt 20 and two lines are arranged, and a fireproof board 21 is arranged at the connection between the fire-proof roller shutter and the parking belt. A fixed curtain 3 is arranged between the arched cave roofs, and a movable roller shutter 2 is arranged under the shutter box 8; a reversible smoke exhaust fan 4 is arranged between two semicircular arc-shaped fixed curtains to realize the closed Smoke exhaust or air supply of the tunnel; on the two vertical tunnel walls under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com