Honeybee royal jelly and honey mixed freeze-drying powder and production method thereof

A production method and technology of royal jelly, applied in the field of health care products, can solve the problems such as temperature should not be too low, inconsistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

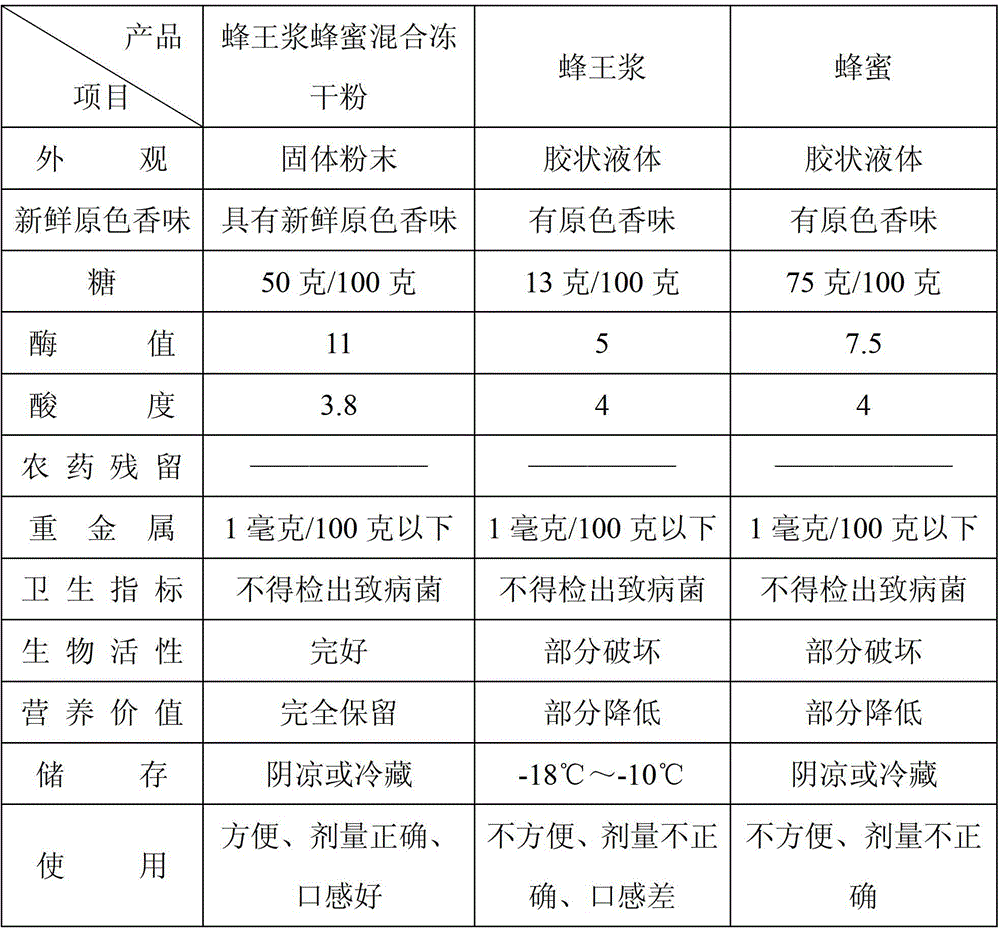

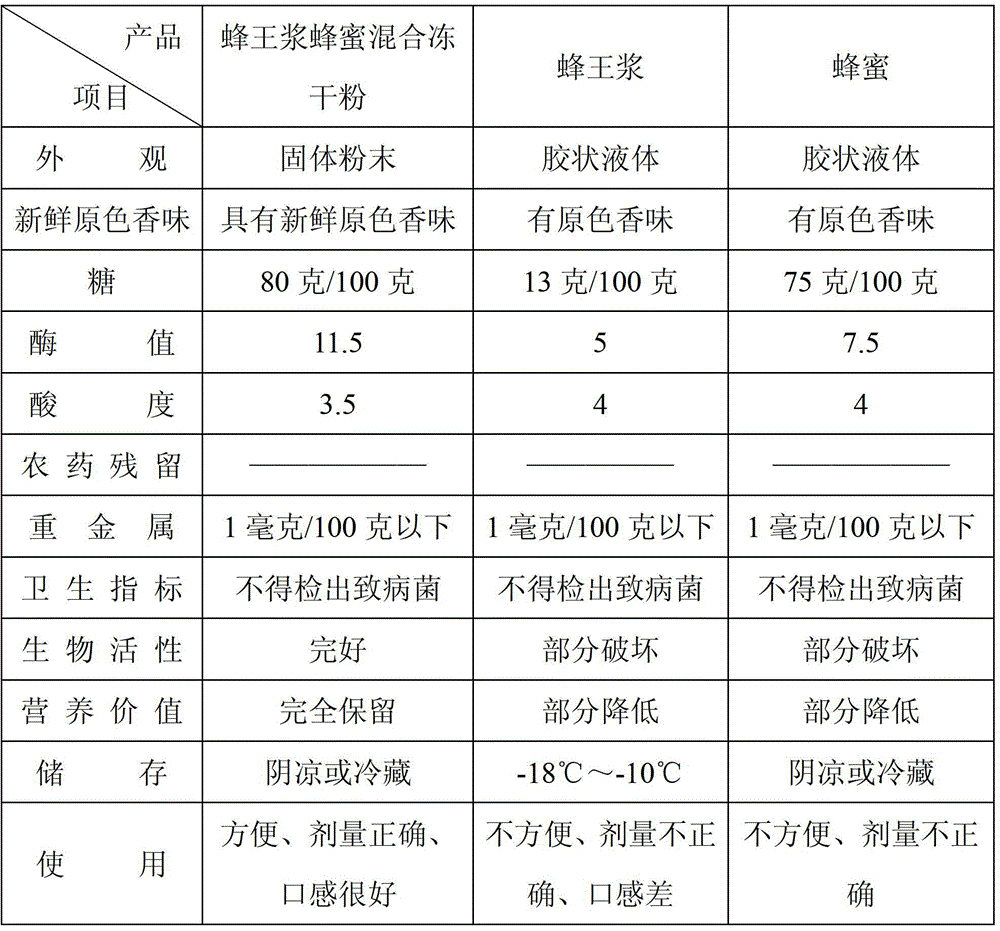

[0029] This implementation provides a kind of royal jelly honey mixed freeze-dried powder, which includes royal jelly and honey, and the described royal jelly and honey are in the state of freeze-dried powder that dissolves together, wherein the weight of royal jelly and honey The content ratio is: 50 parts by weight of liquid honey and 50 parts by weight of slurry royal jelly.

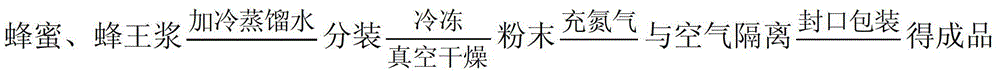

[0030] Such as figure 1 As shown, the production method of a royal jelly honey mixed freeze-dried powder provided in this embodiment is to uniformly mix 50 parts by weight of liquid honey with 50 parts by weight of slurry royal jelly, and then add cold distilled water to the water The content accounts for 30% of the weight of the mixed solution, and then the diluted mixed solution is divided into 20 ml bottles, and the bottle is put into a freeze-drying box, and the temperature is rapidly dropped to -15°C, so that the diluted mixed solution freezes. The ice forms an ice shelf structure and is then va...

Embodiment 2

[0033] This implementation provides a kind of royal jelly honey mixed freeze-dried powder, which includes royal jelly and honey, and the described royal jelly and honey are in the state of freeze-dried powder that dissolves together, wherein the weight of royal jelly and honey The content ratio is: 50 parts by weight of liquid honey and 10 parts by weight of slurry royal jelly.

[0034] The production method of a royal jelly honey mixed freeze-dried powder provided in this embodiment is to mix 50 parts by weight of liquid honey with 10 parts by weight of slurry royal jelly, and then add cold distilled water until the water content reaches 100%. 50% of the weight of the mixed solution, then divide the diluted mixed solution into 50 ml bottles, put the bottles in a freeze-drying box, and quickly drop the temperature to -40°C to freeze the diluted mixed solution to form ice frame structure, and then continuously dried under vacuum until the moisture content is less than 0.01%. F...

Embodiment 3

[0043] This implementation provides a kind of royal jelly honey mixed freeze-dried powder, which includes royal jelly and honey, and the described royal jelly and honey are in the state of freeze-dried powder that dissolves together, wherein the weight of royal jelly and honey The content ratio is: 50 parts by weight of liquid honey and 5 parts by weight of slurry royal jelly.

[0044] The production method of a royal jelly honey mixed freeze-dried powder provided by the invention is characterized in that 50 parts by weight of liquid honey and 5 parts by weight of slurry royal jelly are uniformly mixed, and then cold distilled water is added to reach the water content Accounting for 70% of the weight of the mixed solution, then the mixed solution is divided into 100 milliliters of bottles, and the bottle is put into a freeze-drying box to carry out ultra-low temperature freeze-drying. First, the mixed solution after cooling to the dilution freezes to form an ice shelf structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com