Gravity shuttling type intensive warehousing method and device

A shuttle-type and gravity technology, which is applied to the storage method and equipment field of intensive warehouses, can solve the problems of low delivery efficiency, and achieve the effects of high delivery efficiency, good stability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

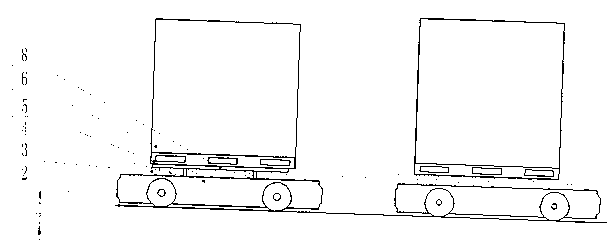

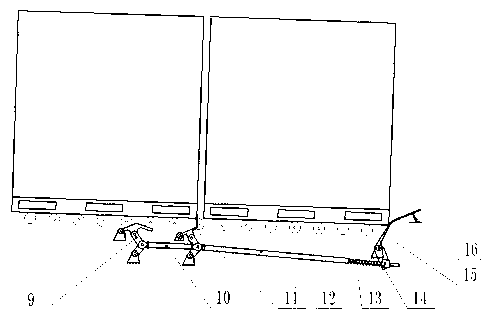

[0048] Embodiment 1, the deceleration and separation device of the mechanical transmission structure, see the attached Figure 1-5 .

[0049] 1. Storage

[0050] The pallet 5 and the unit goods 6 are placed on the flat shuttle car 4 with the jacking function by a forklift or a stacker. At this time, the shuttle car jacking device 8 is in the jacking position, and the flat shuttle car 4 with the jacking function will After the pallet is transported to the designated cargo space, the shuttle car jacking device 8 falls, and the pallet 5 together with the unit cargo 6 is placed on the unpowered roller table.

[0051] 2. storage

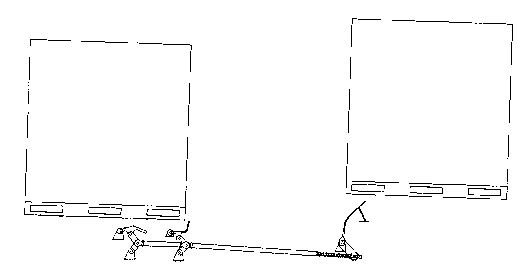

[0052] When storing the first loaded pallet, the flatbed shuttle 4 with jacking function stops at a pallet position in front of the deceleration and separation device 7, and the shuttle jacking device 8 falls. At this time, the pallet 5 together with the unit cargo 6 is placed on the unpowered On the roller table 3, the pallet 5 and the unit cargo ...

Embodiment 2

[0056] Embodiment 2, the deceleration and separation device of the hydraulic transmission structure, see the attached Figure 1-3 ,6-8.

[0057] The deceleration and separation device of the hydraulic transmission structure includes a rocker arm driven by a cargo pallet, an active hydraulic cylinder connected to the rocker arm, and two parallel slave hydraulic cylinders driven by the active hydraulic cylinder. The two slave hydraulic cylinders They are respectively connected with the decelerating and blocking mechanisms.

[0058] 1. Storage

[0059] The pallet 5 and the unit goods 6 are placed on the flat shuttle car 4 with the jacking function by a forklift or a stacker. At this time, the shuttle car jacking device 8 is in the jacking position, and the flat shuttle car 4 with the jacking function will After the pallet is transported to the designated cargo space, the shuttle car jacking device 8 falls, and the pallet 5 together with the unit cargo 6 is placed on the unpowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com