Rotary column type portal crane slewing anchoring device

A portal crane and slewing anchoring technology, applied in cranes and other directions, can solve the problems of passive rotation of cranes and hidden dangers of equipment safety, and achieve the effect of improving the scope of use and improving the safety of wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

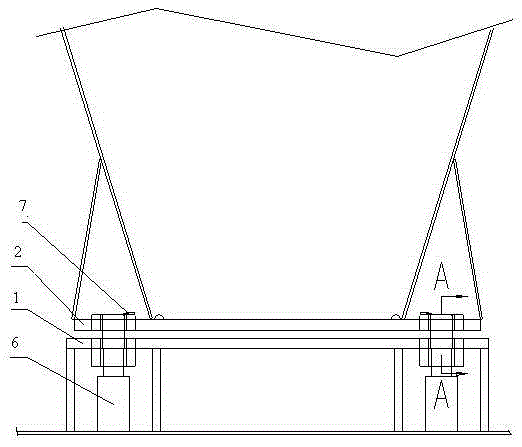

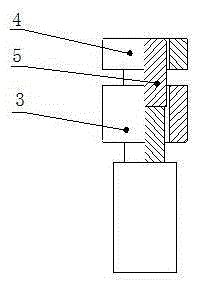

[0017] see figure 1 — figure 2 , the present invention relates to a rotary anchoring device for a column type portal crane, comprising a fixed base 1 and a rotating base 2, the rotating base 2 is welded to the lower column of the portal crane, the fixed base 1 is connected to the door of the portal crane frame welding, the rotating base 2 is located above the fixed base 1, and the lower guide rod seat 3 and the upper guide rod seat 4 are respectively installed on the corresponding positions of the fixed base 1 and the rotating base 2. A guide rod 5 is arranged in the seat 3 and the upper guide rod seat 4, and the guide rod 5 is connected with the hydraulic push rod 6 installed on the fixed base 1, and the guide rod 5 can be guided on the upper guide rod seat 4 and the lower guide rod seat. Rod base 3 moves inside, and a limit switch 7 is installed on the upper guide rod base 4. When the rotary column portal crane is not working, the boom of the crane is first rotated in plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com