wall pile frame structure

A frame structure and frame technology, applied in water conservancy engineering, marine engineering, construction, etc., can solve problems such as high requirements for foundation conditions, large amount of sand and gravel materials, and increased construction difficulty, and achieve strong foundation adaptability and component pre-system. High, overcoming poor durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

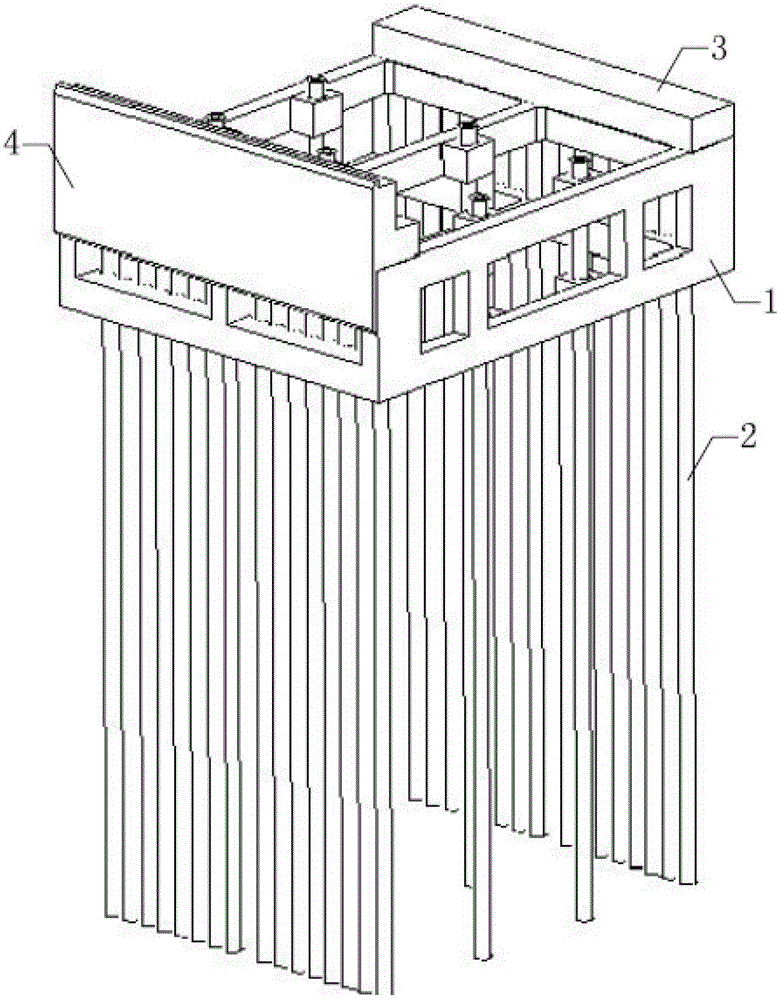

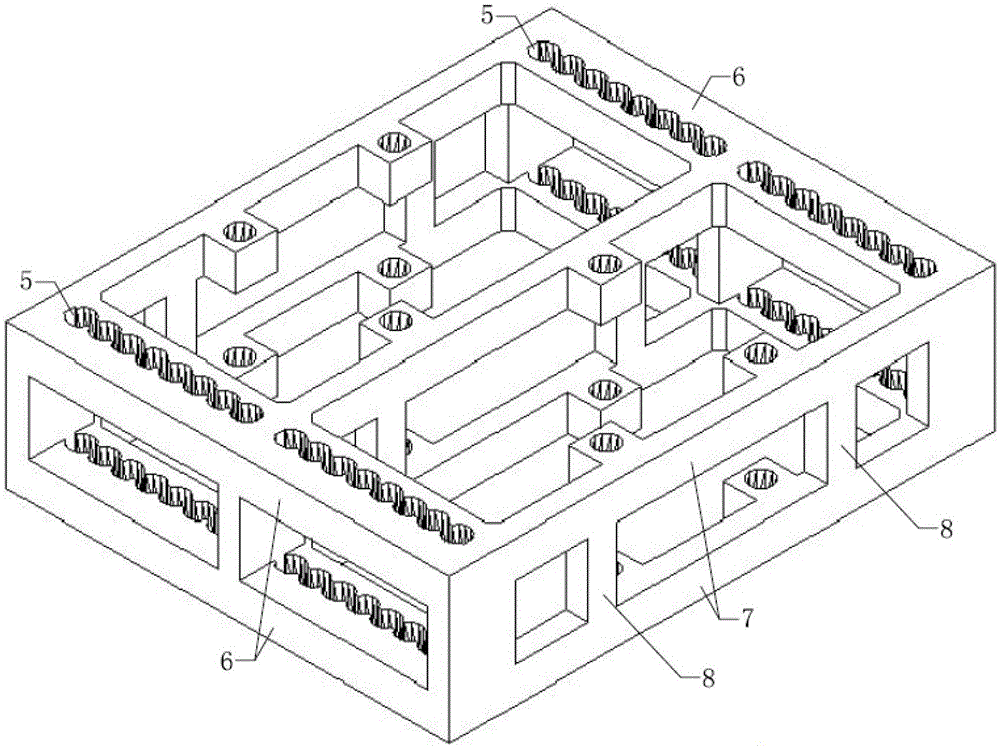

[0022] See accompanying drawing for details, the technical solution of the present invention is to provide a kind of wall pile frame structure, comprise prefabricated concrete frame 1 and wall pile 2, be provided with several wall pile holes 5 along its longitudinal direction on the front and rear end beams of precast concrete frame, wall pile Several prefabricated piles penetrate through the wall pile holes and connect to form the wall pile foundation. The prefabricated concrete frame is placed on the upper part of the wall pile, and backfill soil or sand and gravel materials 14 are placed inside the prefabricated concrete frame. The cast-in-place concrete cap beam 3 and breast wall 4 on the top of the wall pile make the wall pile and the prefabricated concrete frame form an integral structure. The wall pile i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com