Electric tailgate speed control method and device

A speed control, tailgate technology, applied in the field of automation, can solve problems such as door lock damage, reduced safety factor, support structure damage, etc., to achieve the effect of stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

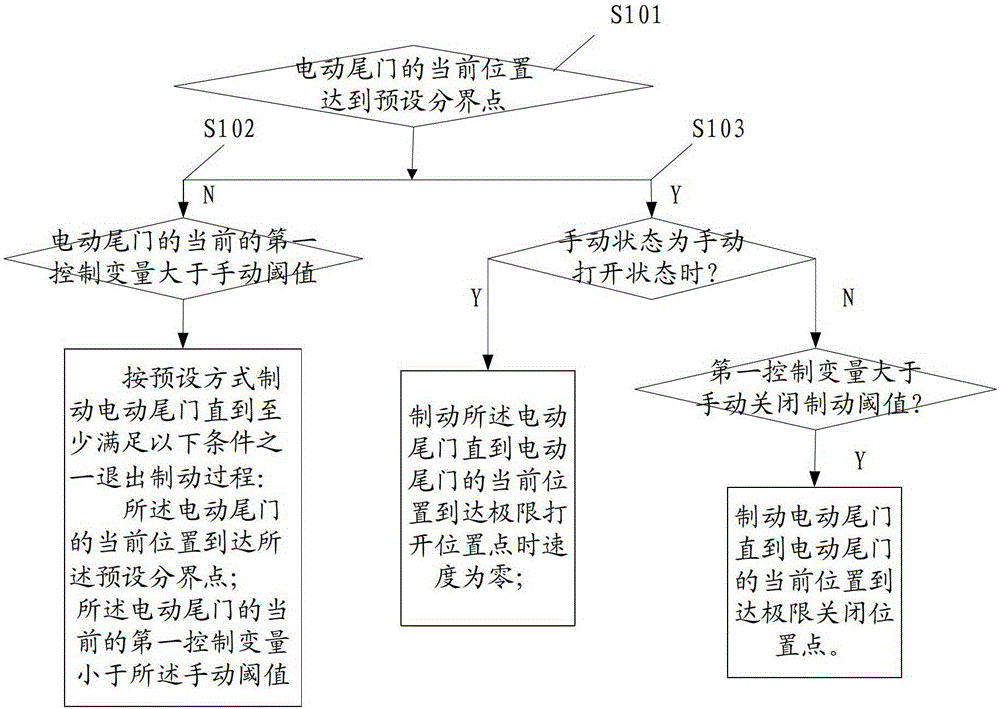

[0120] Such as Figure 9 As shown, the present invention provides a second embodiment of the electric tailgate speed control method, including:

[0121] Step S301: The electric tailgate enters the manual state from the control command of the stop state, and determines whether the manual state is the manual open state? If it is in the manual open state, then enter step S302;

[0122] Step S302: When the manual state is the manual open state, judge whether the current position of the electric tailgate has reached the preset opening threshold; if the current position of the electric tailgate has not reached the preset opening threshold, enter Step S303, if the current position of the electric tailgate reaches the preset opening threshold, go to step S305;

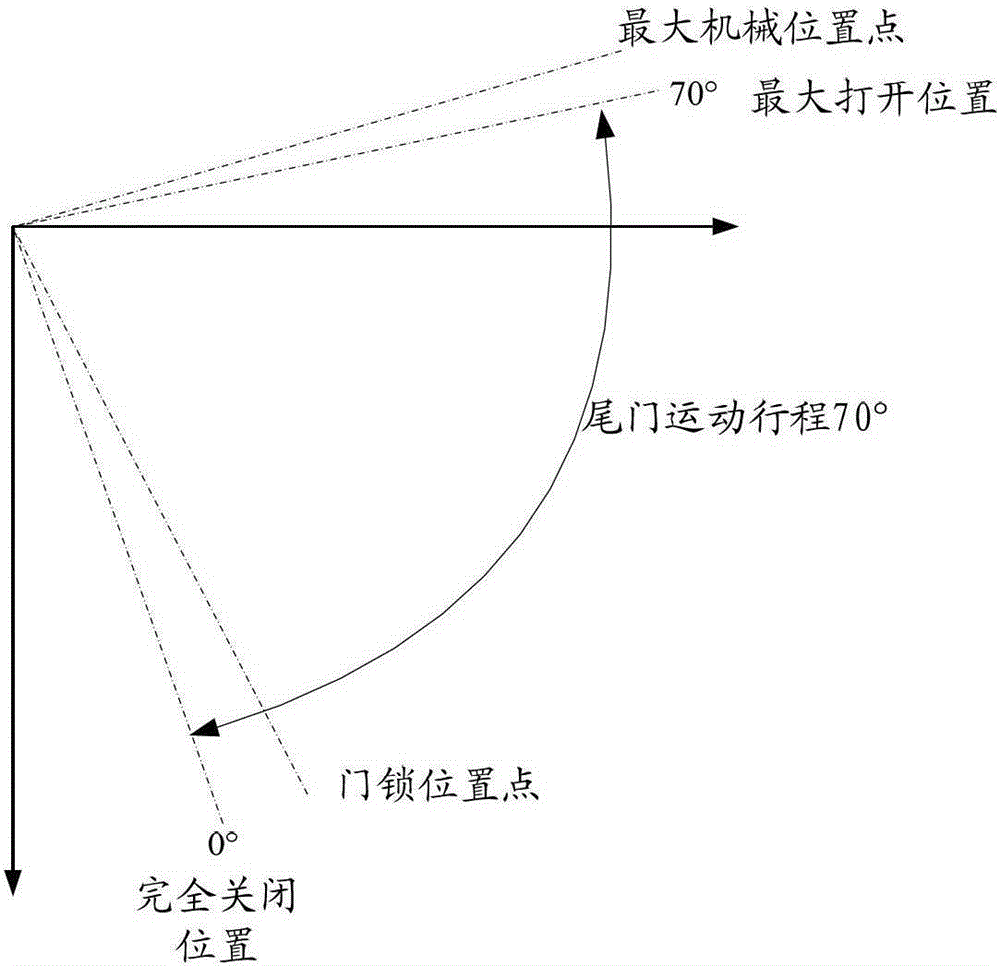

[0123] Such as Figure 10 As shown, it is a schematic diagram of the preset dividing point of the electric tailgate, and the preset opening dividing point is a position 10° away from the maximum position point.

[0124] St...

no. 3 example

[0129] Such as Figure 11 As shown, the present invention provides a third embodiment of the electric tailgate speed control method, including:

[0130] Step S401: The electric tailgate enters the manual state from the control command of the stopped state, and determines whether the manual state is the manually closed state? If it is in the manual closing state, enter step S402;

[0131] Step S402: When the manual state is the manual closing state, judge whether the current position of the electric tailgate has reached the preset closing threshold; if the current position of the electric tailgate has not reached the preset closing threshold, enter Step S403, if the current position of the electric tailgate reaches the preset closing threshold, go to step S405;

[0132] Such as Figure 10 As shown, it is a schematic diagram of the preset dividing point of the electric tailgate, and the preset closing dividing point is a position 20° away from the minimum position point.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com