Vending mechanism of vending machine

A technology for vending machines and goods, which is applied in the direction of instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items. Convenience and other problems, achieve the effect of coherent and stable cargo transportation, reduce the failure rate of cargo lanes, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

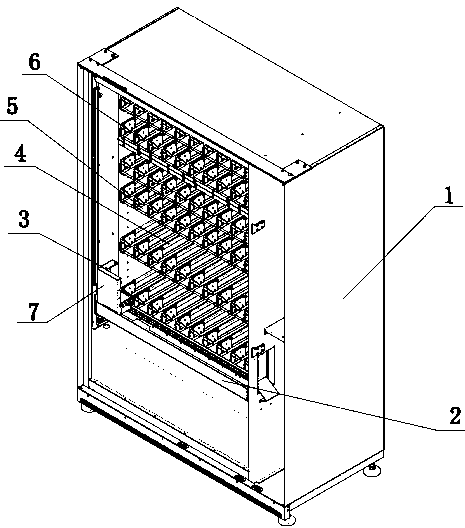

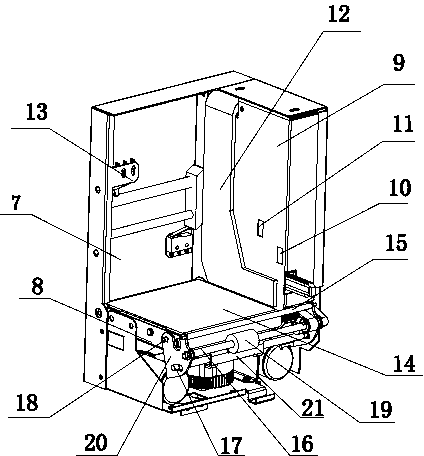

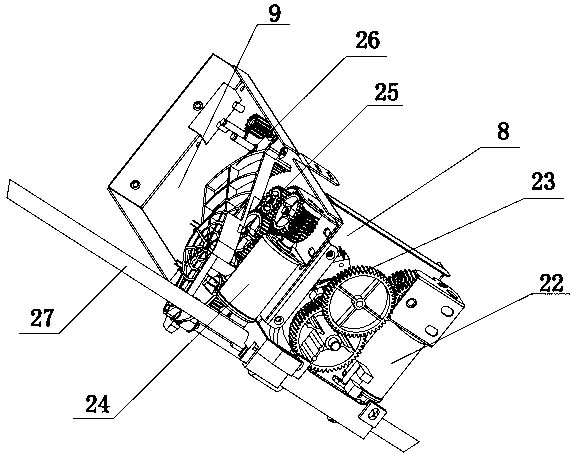

[0025] As shown in the figure, a vending mechanism for a vending machine includes a goods supply unit, a pick-up unit, and a delivery unit arranged in the vending machine cabinet 1, and the goods supply unit includes a cargo lane 5 co-located in the cabinet 1 , the side plates 4 on both sides of the goods lane 5 are fixedly arranged, the baffle plate 6 arranged at the front end of the side plate 4 and the socket used in conjunction with the baffle plate 6, the baffle plate 6 is used to block the goods, and the pick-up unit includes a cooperating arrangement on the The lifting platform 2 in the cabinet 1 and the pick-up device 3 cooperating with the lifting platform 2, the lifting platform 2 is fixedly provided with a traverse guide rail 27 and a traverse motor, and the traverse guide rail 27 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com