Device for connecting plug and socket

A technology for connecting plugs and sockets, which is applied in the field of motor cable equipment design to achieve tight plugging, avoid poor contact or stress damage, and achieve the effect of parallel force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

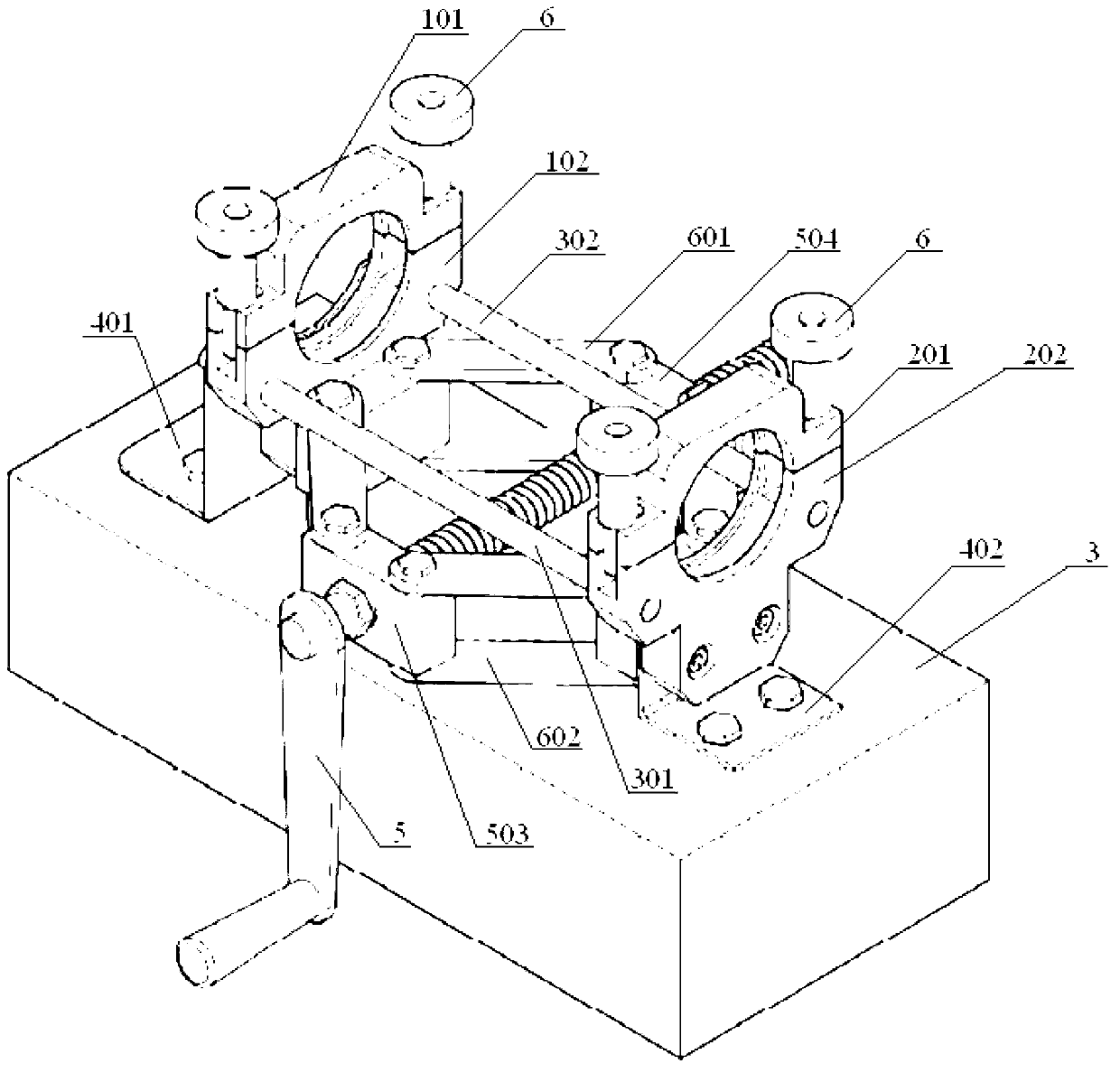

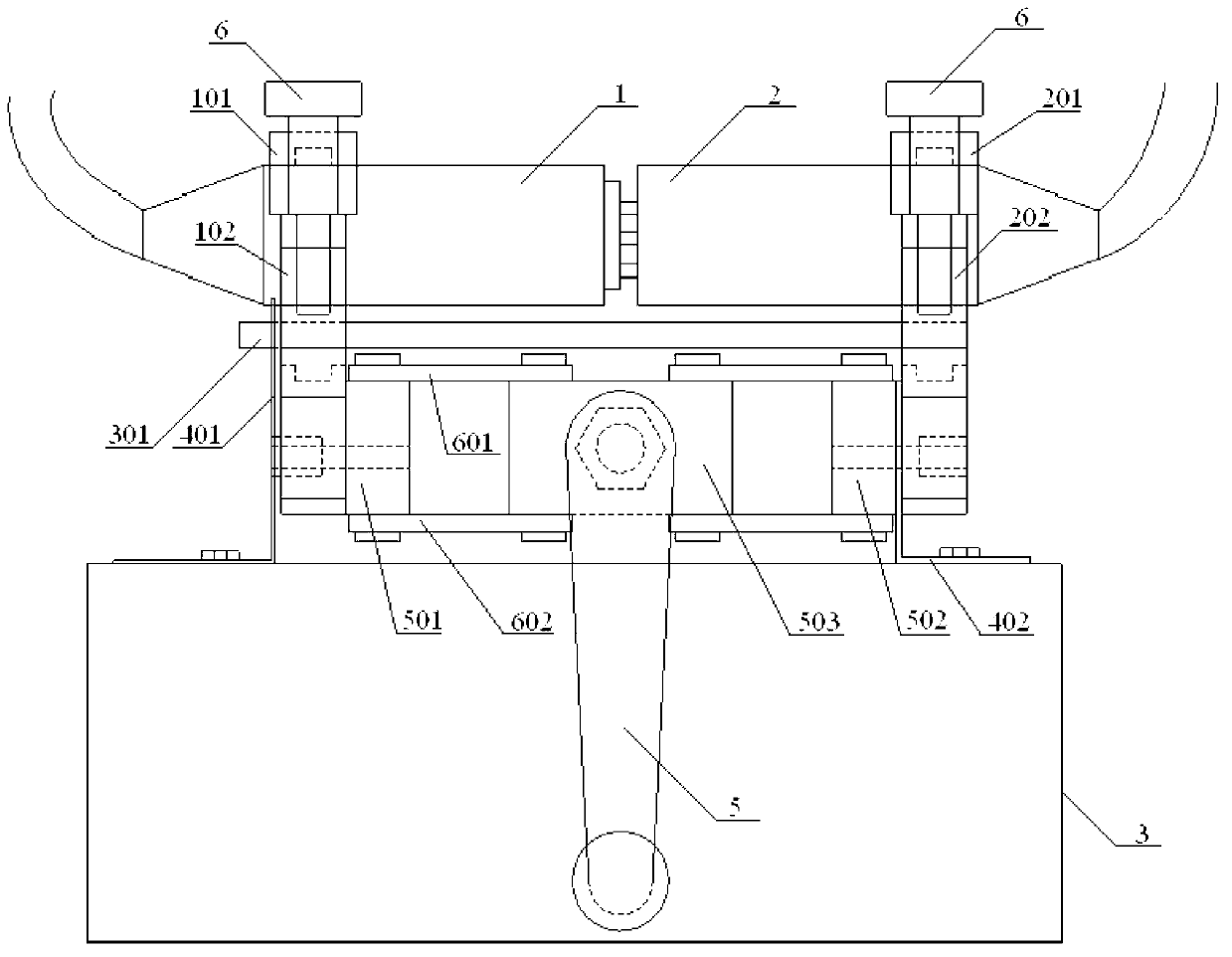

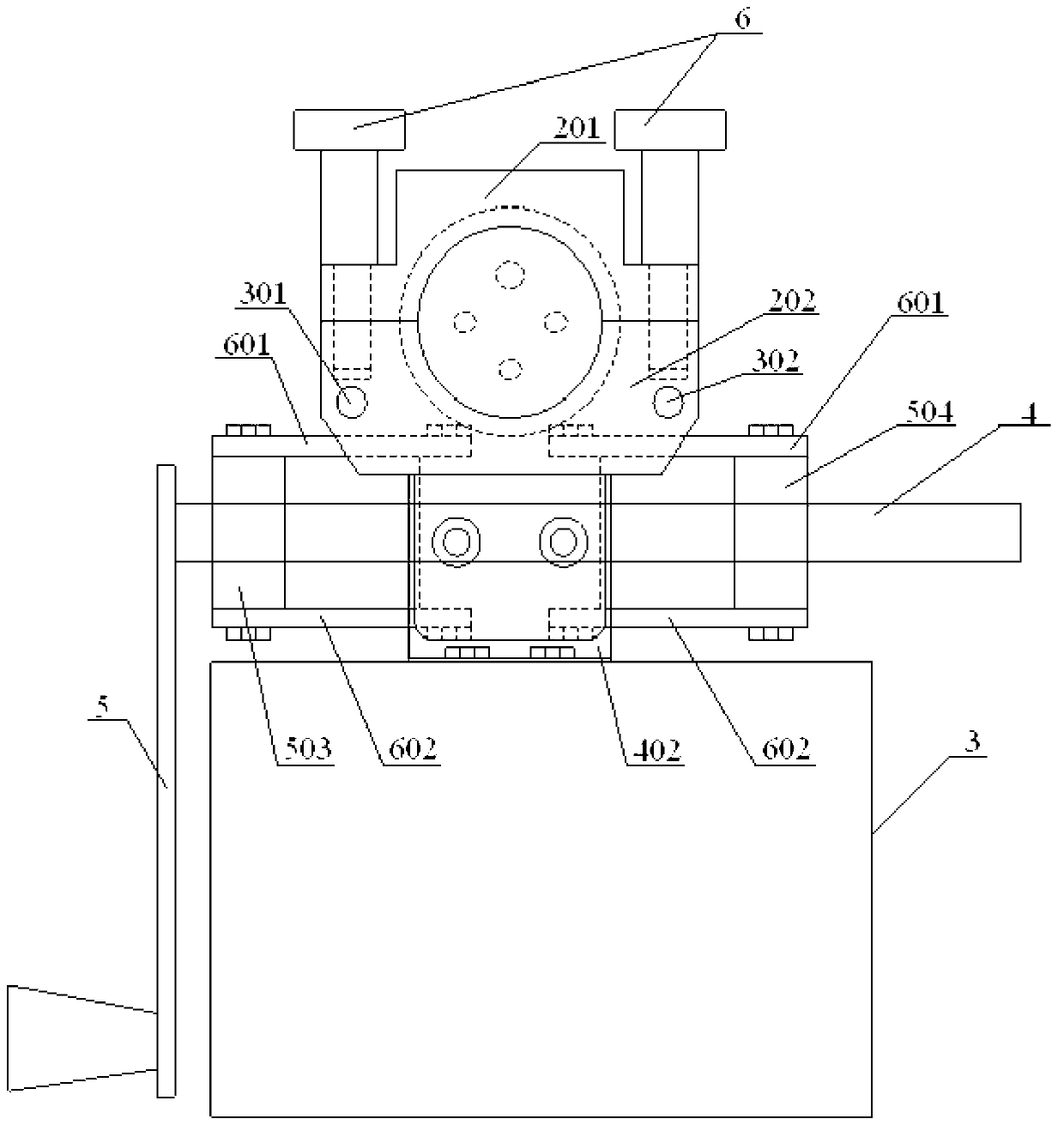

[0021] The specific implementation manners provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] see Figure 1-4 , a device for connecting a plug and a socket provided by an embodiment of the present invention includes: a first snap ring seat for fastening the plug 1 or the socket 2, a second snap ring for fastening the socket 2 or the plug 1 Seat, guide rail mechanism for sliding the first snap ring seat, support mechanism for fastening the guide rail mechanism and the second snap ring seat, force applying mechanism and base for controlling the relative sliding of the first snap ring seat along the guide rail mechanism 3 . Wherein, the first clasp seat is slidably connected with the guide rail mechanism, and the two can realize relative sliding in the actual working process. At the same time, one end of the guide rail mechanism is fixedly connected to the supporting mechanism, and the other end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com