A cold storage board edge milling machine

A cold storage board and edge milling machine technology, which is applied in the direction of milling cutters, milling machine equipment, milling machine equipment details, etc., can solve problems such as thermal insulation performance degradation, insertion quality defects, plate insertion interface deformation, etc., to achieve tight insertion and save repairing The effect of time on the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

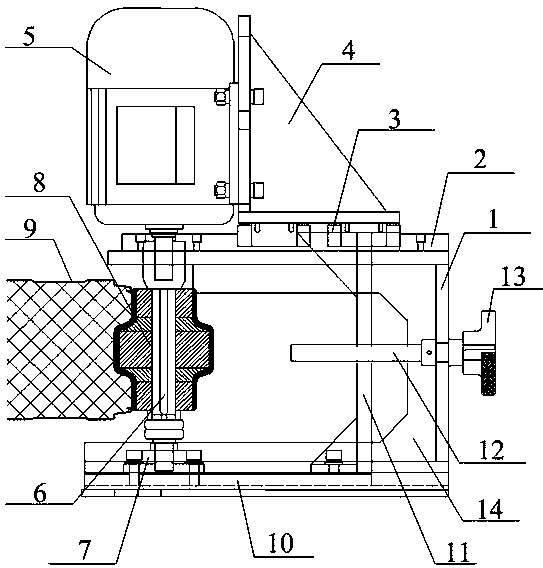

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises frame 1, and iron plate reinforcing rib 14 is welded in frame 1, and described frame 1 is the rectangular frame of one end opening, and described frame 1 top is provided with linear slide rail 2, and linear slide rail 2 A slidable slider 3 is arranged on the top, the motor mount 4 is fixed on the slider 3, the motor 5 is fixed on one side of the motor mount 4, the motor mount 4 is a right triangle, and the motor 5 is vertically fixed on the motor mount. On the right angle side of seat 4, rotating shaft 6 is vertically installed directly below motor 5, milling cutter 8 is installed on rotating shaft 6, and the lower end of rotating shaft 4 is installed on bearing seat 7, and described frame 1 below is provided with groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com