Aquaculture turn-scoop-type wave generator

A technology for aquaculture and generators, applied in the fields of application, fish farming, climate change adaptation, etc., can solve problems such as poor efficiency, low energy conversion efficiency, and waste of electric energy, so as to promote uniform distribution, reduce farming costs, and improve farming effect of effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

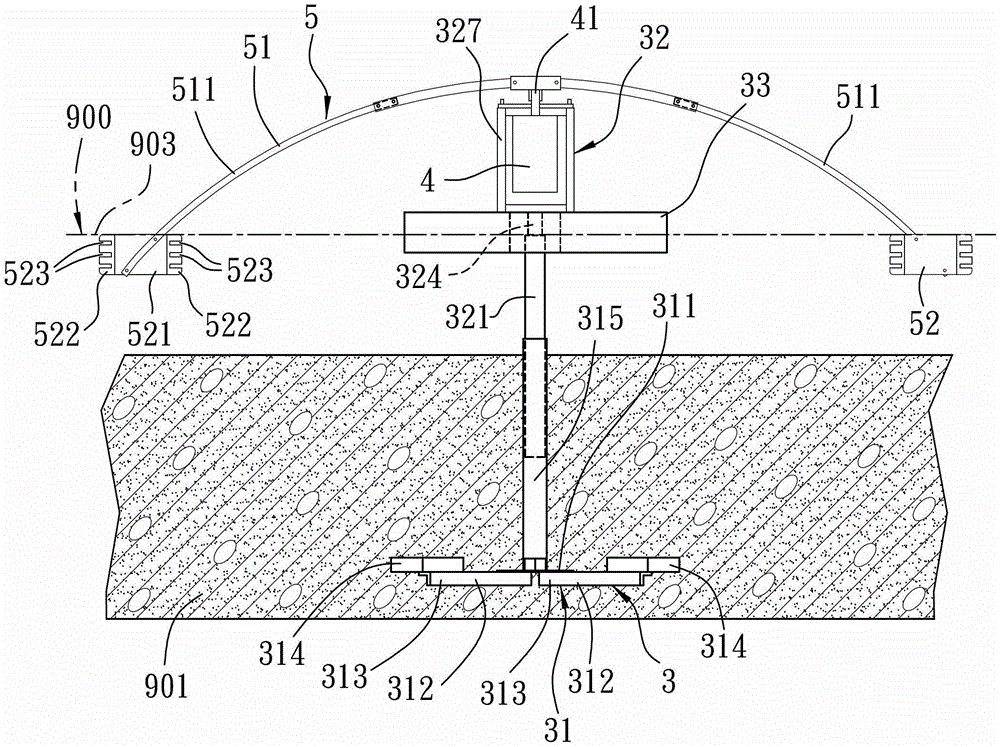

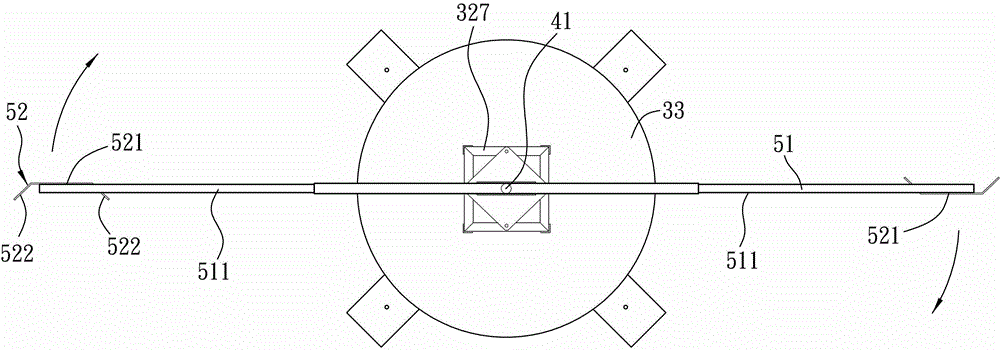

[0023] Such as figure 1 , 2 As shown, the preferred embodiment of the rotary dipper type water wave generator for aquaculture of the present invention is suitable for being installed in a culture pond 900, and piled on the pond bottom soil layer 901 at the bottom of the culture pond 900, and can be used to promote cultivation The pool water in the pool produces currents and waves.

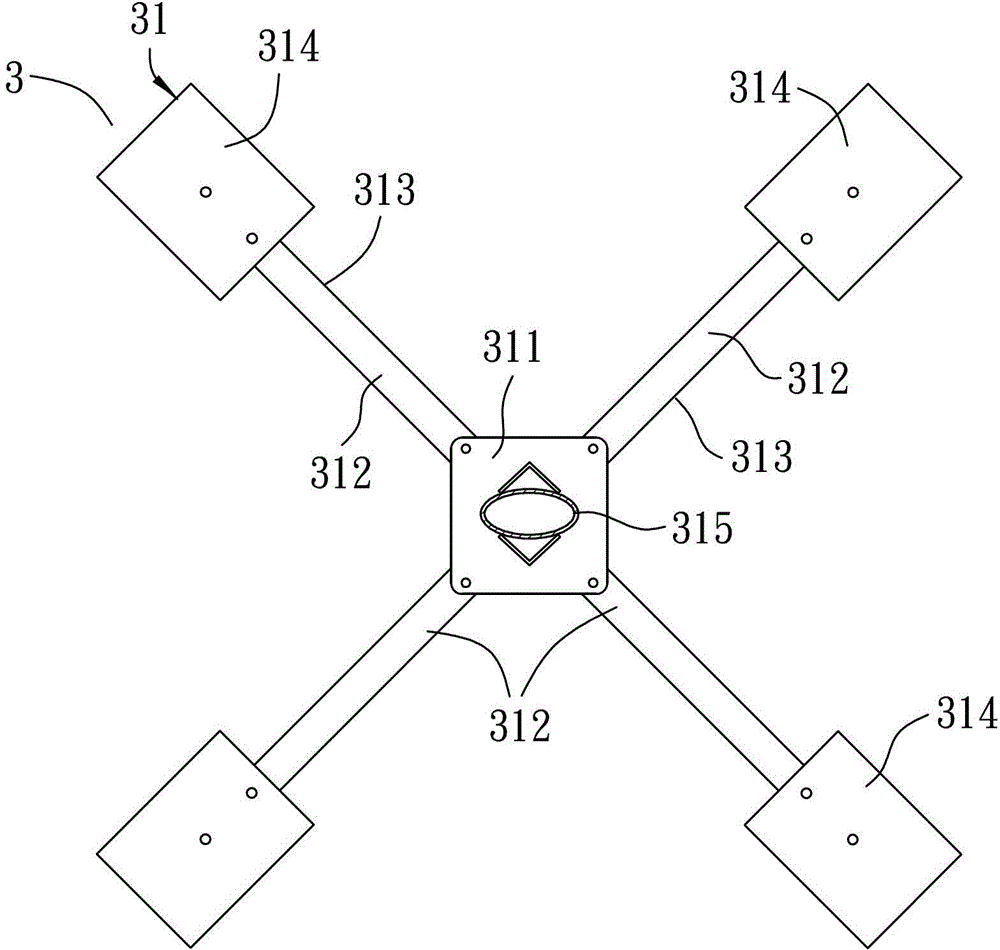

[0024] The aquaculture rotating dipper type water wave generator includes a floating support mechanism 3 fixed on the bottom soil layer 901 and extending upwards out of the pool surface 903, and a floating support mechanism 3 fixed on the floating support mechanism 3 and located on the pond surface of the aquaculture pond. The reduction motor 4 above 903, and a water wave generating mechanism 5 installed on the reduction motor 4 and extending under the pool surface 903 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com