Device for automatically inducting and tightly sucking micro-channel side boards

An automatic sensing and micro-channel technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of not being able to automatically sense whether the side plate is placed, there is no simple installation and fixing method, increasing costs, etc. Simple, highly automated, highly reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

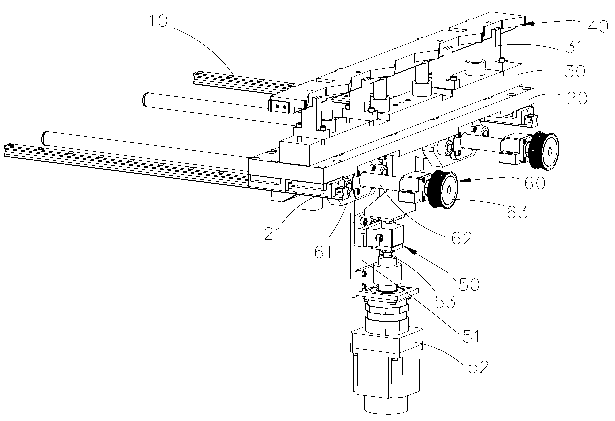

[0018] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] see Figure 1 to Figure 5 , the micro-channel side plate automatic induction suction device of the present invention is fixed on the frame (not shown in the figure), and the frame is provided with parallel guide rails 10, and the guide rails 10 hold the base 20, and the base Sliders 21 are arranged under both sides of the seat 20, and the sliders 21 are clamped on the guide rail 10, the base 20 can move back and forth along the guide rail 10, and a support seat 30 is arranged above the base 20 , above the support base 30 are fixed support blocks 31 arranged at intervals.

[0020] The microchannel side plate automatic induction suction device includes a suction mechanism 40, a lifting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com