Split-type measuring glass on packaging machine

A split type, packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of difficult weight adjustment, weight can not be adjusted, etc., to achieve high efficiency, waste, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

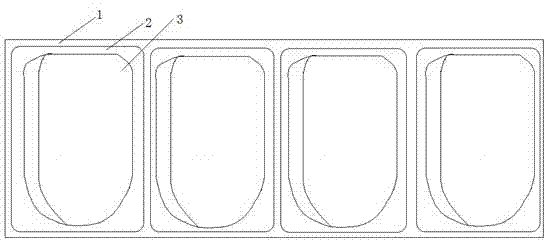

[0015] see figure 1 As shown, a split measuring cup on a packaging machine includes a base 1, a chassis 2, and a measuring cup main body 3. The base 1 is provided with a chassis 2, and the chassis 2 is provided with a measuring cup main body 3. The measuring cup main body (3 ) has a footprint-shaped structure, there are four chassis 2, and four measuring cup bodies 3, the chassis 2 and the measuring cup bodies 3 are respectively connected and integrated, and each of the measuring cup bodies 3 is a separate body , the depth of the main body 3 of the measuring cup is 5cm-8cm.

[0016] To sum up, the present invention decomposes the original four integrated measuring cups into four individual measuring cups, and the replacement time is increased to only 3 minutes. This design solves the waste of measuring cup materials, and has the advantages of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com