A compressor flow regulation system based on clearance regulation

A technology of flow regulation and flow regulation device, applied in the field of compressors, can solve the problems of increasing system complexity and complex system structure, and achieve the effect of simplifying the system structure and control scheme, and avoiding installation and debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

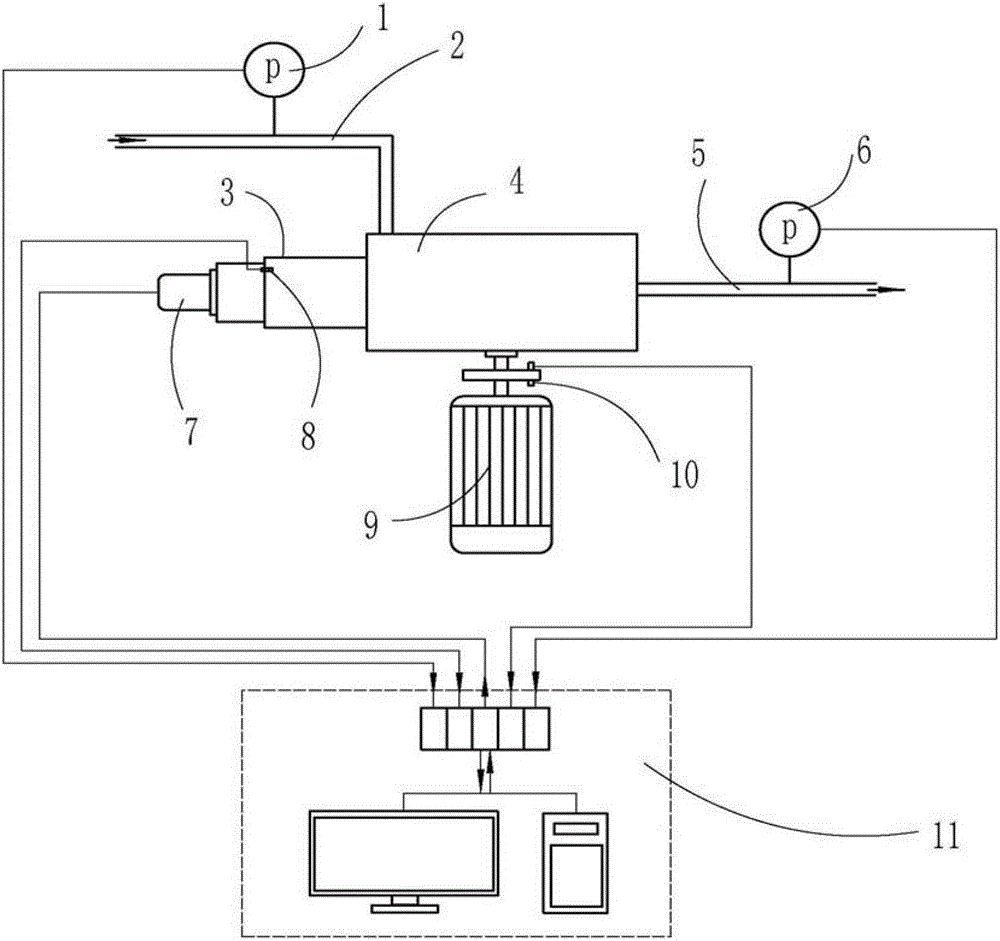

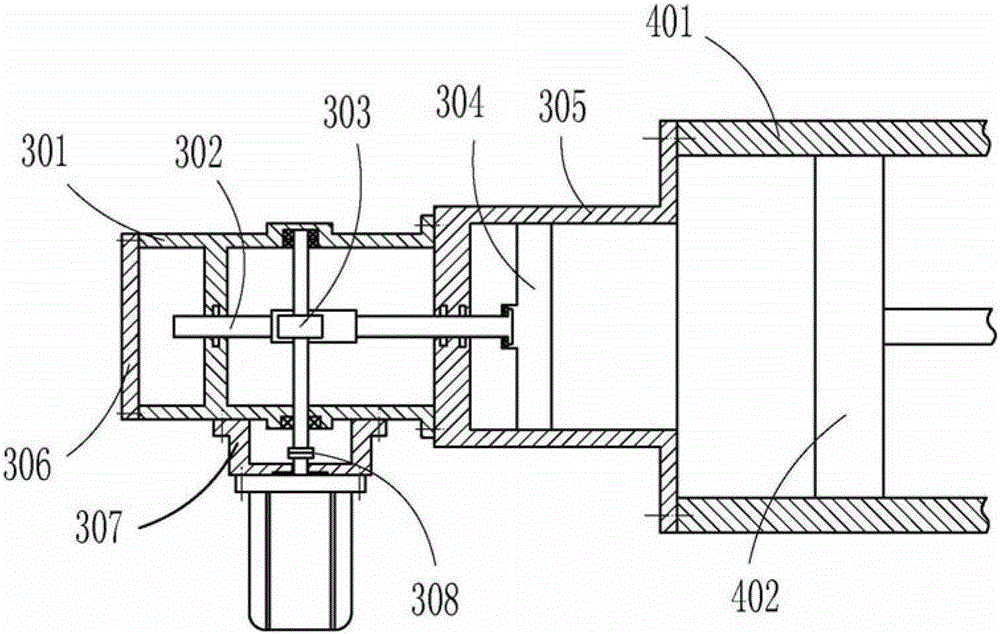

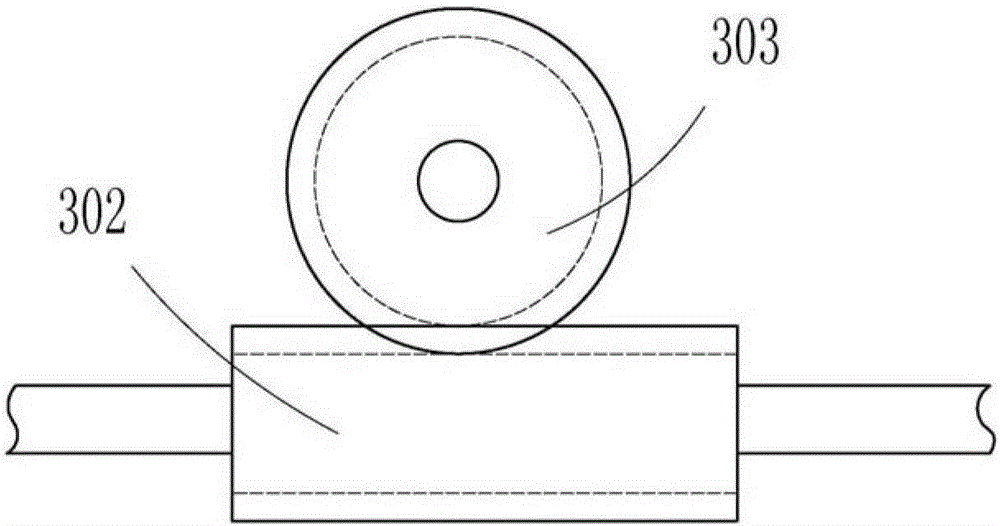

[0027] see figure 1 , the compressor flow regulation system based on clearance adjustment in this embodiment is to install the flow regulating device 3 on the compressor cylinder 4, and use the monitoring system 11 to drive the actuator motor 7 to control the movement of the regulating piston 304 in the flow regulating device 3, so as to realize The volume change of the regulating cylinder 305 in the flow regulating device 3 is used to control the clearance volume of the compressor cylinder 4 by the volume change of the flow regulating cylinder 305, so as to realize the automatic stepless regulation of the flow of the compressor.

[0028] Setting up a monitoring system includes:

[0029] The suction pressure sensor 1 installed on the compressor suction pipe 2 is used to detect the compressor suction pressure in real time;

[0030] The discharge pressure sensor 6 installed on the compressor discharge pipeline 5 is used to detect the compressor discharge pressure in real time; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com