Touch control graphics structure for embedded capacitive touch screen

一种电容触控屏、图形结构的技术,应用在电数字数据处理、数据处理的输入/输出过程、仪器等方向,能够解决无法满足内嵌式电容触控屏触控灵敏度要求等问题,达到增大触控灵敏度、加大互电容作用、易于检测的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

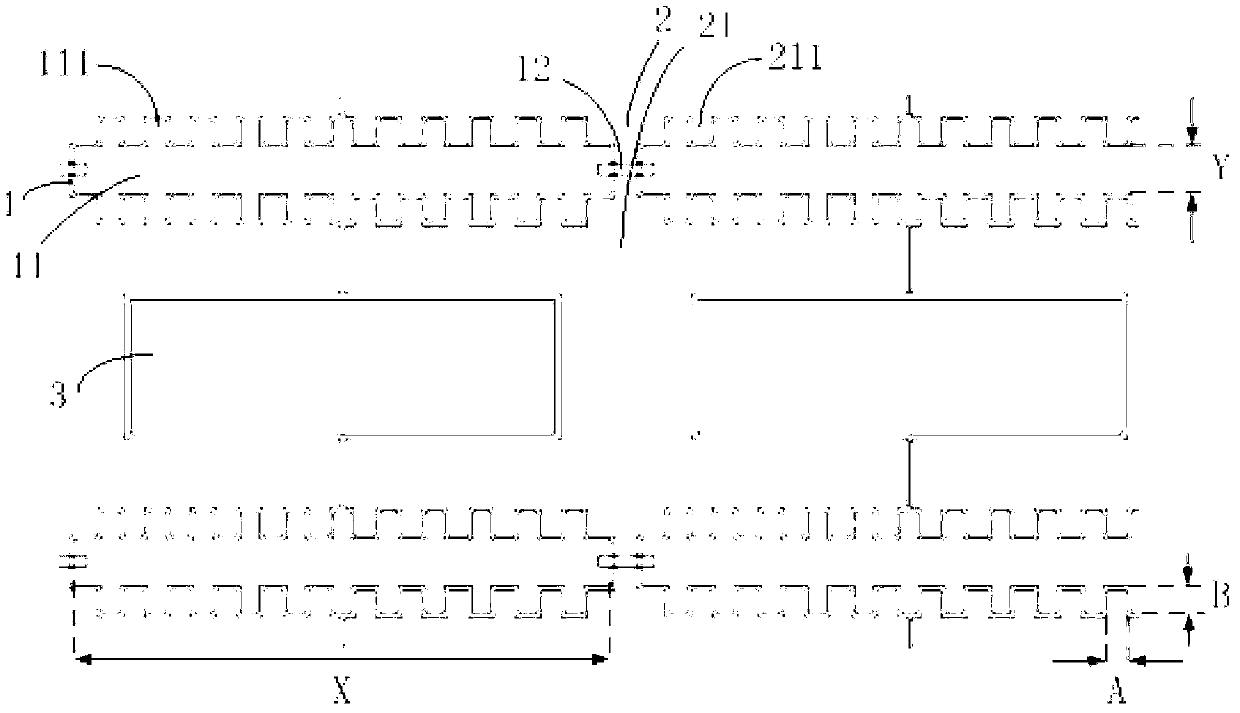

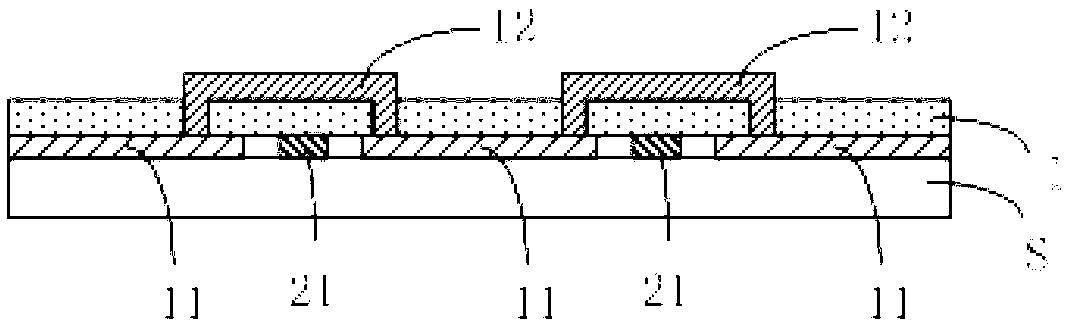

[0042] Please refer to figure 2 , figure 2 It is a schematic diagram of the touch pattern structure of the in-cell capacitive touch screen provided by the first embodiment of the present invention. From figure 2It can be seen from the figure that the touch pattern structure of the embedded capacitive touch screen includes a plurality of mutually insulated driving lines 2 along the first direction, and the driving lines 2 include a plurality of driving electrodes 21 whose overall image is in the shape of an "I" , and the adjacent drive electrodes 21 are electrically connected. The touch graphic structure of the embedded capacitive touch screen further includes a plurality of mutually insulated sensing lines 1 along the second direction, and the sensing lines 1 include a plurality of sensing electrodes 11 and wires 12 connecting adjacent sensing electrodes 11 . At the same time, there is an etching groove between the driving line 2 and the sensing line 1 to insulate each o...

no. 2 example

[0058] Please refer to Figure 6 , Figure 6 It is a schematic diagram of the touch pattern structure of the in-cell capacitive touch screen provided by the second embodiment of the present invention. From Figure 6 It can be seen from the figure that the touch graphic structure of the embedded capacitive touch screen includes a plurality of mutually insulated driving lines 5 along the first direction, and the driving lines 5 include a plurality of driving electrodes whose overall image is in the shape of an "I" 51. In this embodiment, the adjacent driving electrodes 51 are electrically connected to each other so that all the driving electrodes 51 form a whole (that is, the driving line 5). The touch graphic structure of the embedded capacitive touch screen also includes a plurality of mutually insulated sensing lines 4 along the second direction. connect. The driving line 5 and the sensing line 4 are insulated from each other. image 3 Although not shown in , both the dr...

no. 3 example

[0065] Please refer to Figure 7 , Figure 7 It is a schematic diagram of the touch graphic structure of the in-cell capacitive touch screen provided by the third embodiment of the present invention. From Figure 7 It can be seen from the figure that the touch graphic structure of the embedded capacitive touch screen includes a plurality of mutually insulated driving lines 8 along the first direction, and the driving lines 8 include a plurality of driving electrodes 81, and the overall shape of the driving electrodes 81 is similar to The shape of the word "king". In this embodiment, adjacent driving electrodes 81 are electrically connected to each other so that the driving electrodes 81 form a whole (that is, the driving line 8 ). The touch graphic structure of the embedded capacitive touch screen also includes a plurality of mutually insulated sensing lines 7 along the second direction, the sensing lines 7 include a plurality of sensing electrodes 71, and a wire 72 is pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com